10-19

HRX217HYA • HRX217HZA CAM PULLEY/CRANKSHAFT/ PISTON/CYLINDER

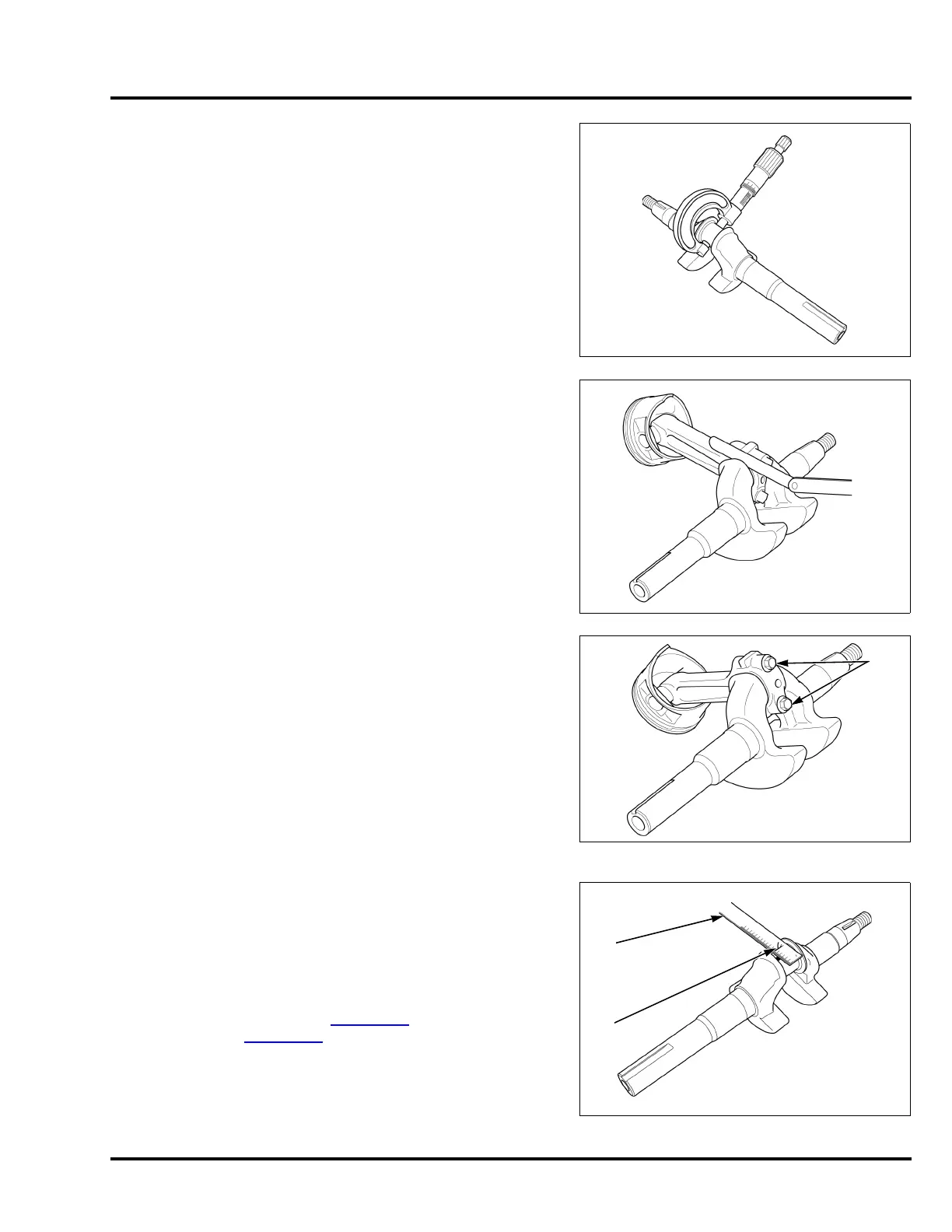

CRANKPIN O.D.

Measure the crankpin O.D. of the crankshaft.

If the measurement is less than the service limit, replace the

crankshaft.

CONNECTING ROD BIG END AXIAL CLEARANCE

Measure the clearance between the connecting rod big end and

crankshaft using a feeler gauge.

If the measurement is more than the service limit, replace the

connecting rod and recheck the clearance.

If the clearance is still more than the service limit with the new

connecting rod, replace the crankshaft.

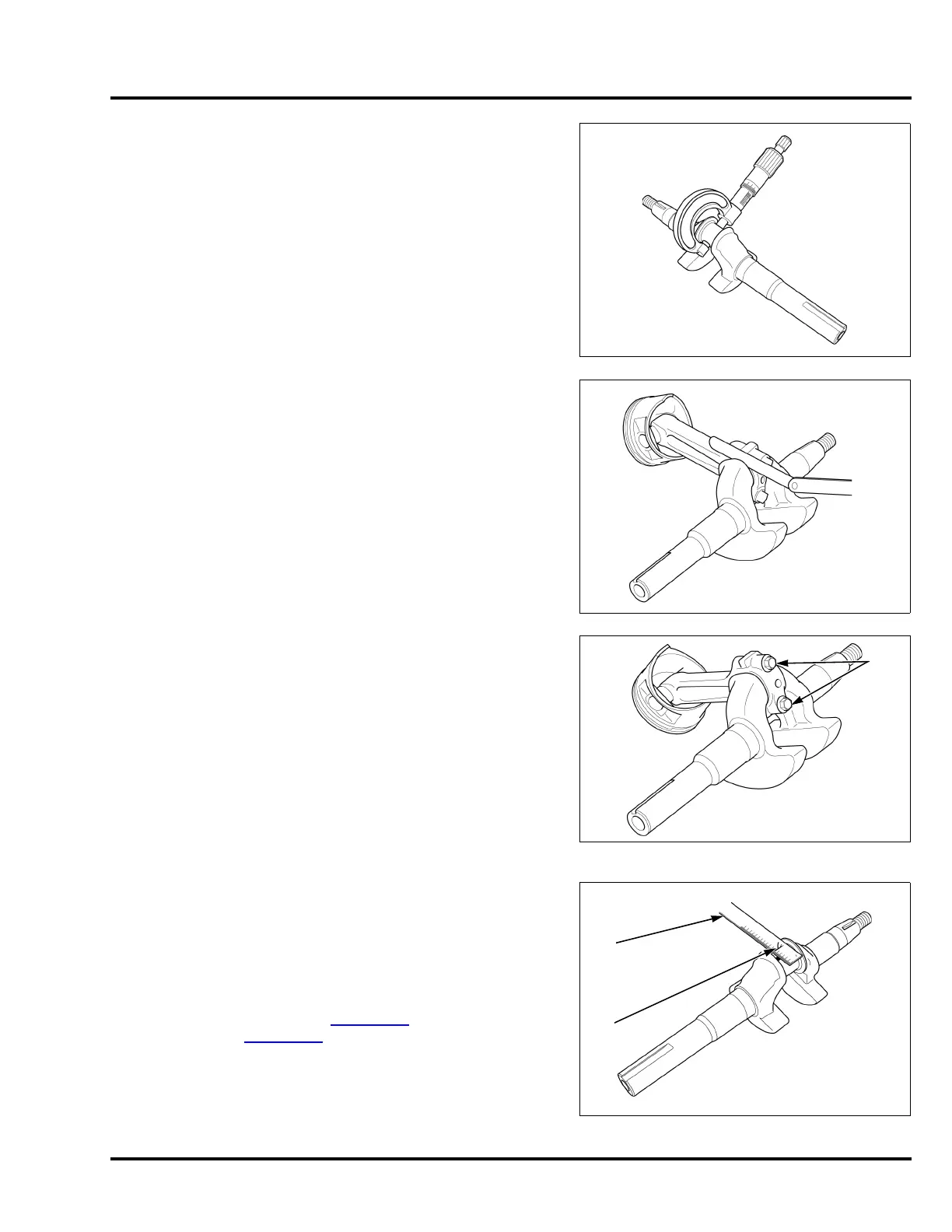

CONNECTING ROD BIG END OIL CLEARANCE

Clean all oil from the crank pin and connecting rod big end surface.

Place a piece of Plastigauge

®

on the crank pin axially, install the

connecting rod and the connecting rod cap.

Apply engine oil to the connecting rod bolt [1] threads and seating

surface.

Tighten the connecting rod bolts to the specified torque.

• Do not rotate the crankshaft while the Plastigauge is in place.

Remove the connecting rod cap and measure the Plastigauge [1]

using a Plastigauge scale [2].

If the clearance is more than the service limit, inspect the following:

– Connecting rod big end I.D. (page 10-18

)

– Crank pin O.D. (page 10-19

)

Replace any part that measures beyond the service limit.

STANDARD: 27.970 – 27.980 mm (1.1012 – 1.1016 in)

SERVICE LIMIT: 27.920 mm (1.0992 in)

STANDARD: 0.10 – 0.50 mm (0.004 – 0.020 in)

SERVICE LIMIT: 0.80 mm (0.031 in)

TORQUE: 12 N•m (9 ft-lb)

STANDARD: 0.040 – 0.063 mm (0.0016 – 0.0025 in)

SERVICE LIMIT: 0.120 mm (0.0047 in)

Loading...

Loading...