SV-DA200 series AC servo drive Function codes

-100-

Numerator of 1

st

electronic gear ratio

Denominator of the

electronic gear ratio

Numerator of 2

nd

electronic gear ratio

Numerator of 3

rd

electronic gear ratio

Numerator of 4

th

electronic gear ratio

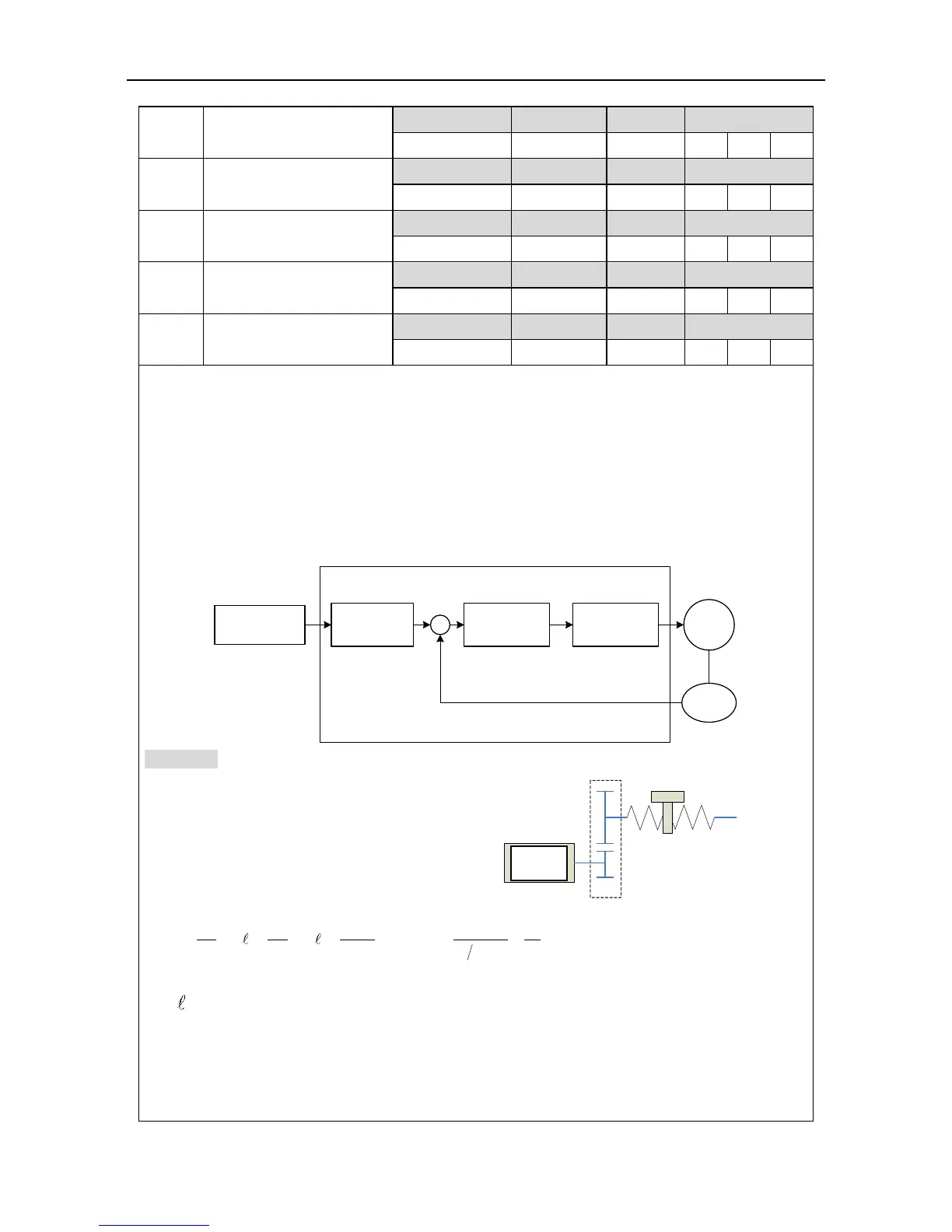

Concept of the electronic gears: for any pulse input, the number and frequency of the pulse

actually received by the drive can be changed by multiplying a certain coefficient and this

coefficient is electronic gear ratio. It can be indicated in two parts: numerator and denominator:

Electronic gear ratio = g1/ g2;

Of which

g1: The numerator of the electronic gear ratio;

g2: The denominator of the electronic gear ratio;

Below is the schematic diagram of the electronic gear ratio in the system:

Deviation

counter

Motor

Encoder

Intermediate

link

Electrical gear

ratio

Input pulse train

Feedback pulse

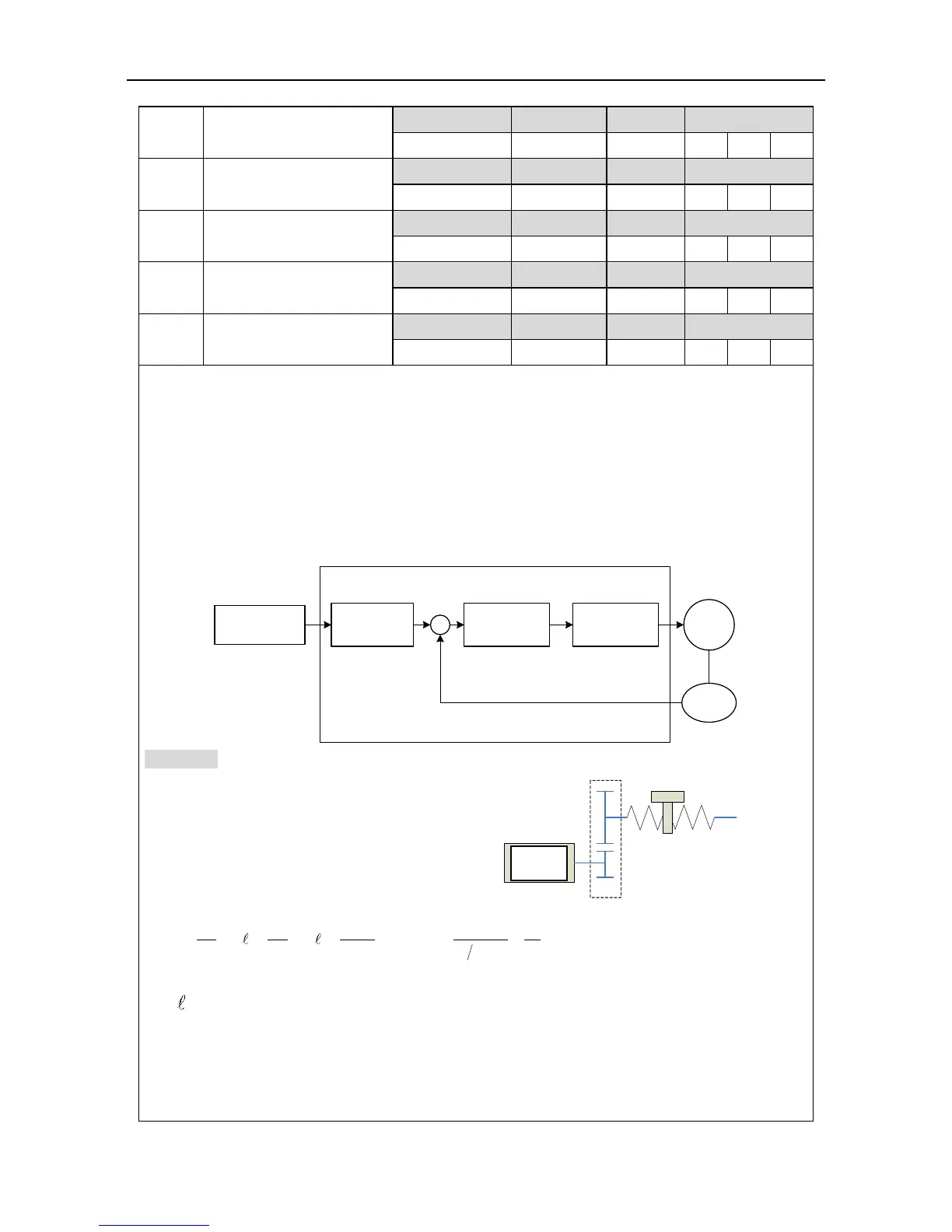

Example: Below is a case where 1 pulse is

equivalent to a feed rate of 10μm

Mechanical specifications:

Feed of the ball screw Pb =10mm;

Reduction ratio n=3/5;

Resolution of the servo motor encoder =10000;

At this time calculate the electronic gear ratio:

3

00

1 10000 50

10 10

2 (3 5) 10 3

g Pt Pt

g S n Pb

· · ·

: Feed rate corresponding to each pulse (mm/pulse);

: Feed rate corresponding to each rotation of the motor (mm/rot).

i.e. in this example, g1=50, g2=3.

Set P0.25 to 50 and P0.26 to 3.

The servo drive has 4 groups of electric gear ratio: P0.25, P0.26, P0.27 and P0.28, P0.29 can

Loading...

Loading...