9 Motion Control Functions

9-14

NJ/NX-series CPU Unit Motion Control User’s Manual (W507)

For details on gear operation, refer to the MC_GearIn (Start Gear Operation), MC_GearOut (End Gear

Operation), and MC_Stop instructions in the NJ/NX-series Motion Control Instructions Reference Man-

ual (Cat. No. W508).

This function specifies the gear ratio between the master axis and the slave axis and starts operation.

Positioning gear operation allows you to set the positions of the master and slave axes at which to start

synchronization. Start positioning gear operation with the MC_GearInPos instruction. End synchroniza-

tion with the MC_GearOut instruction or the MC_Stop instruction.

You can set the gear ratio numerator, gear ratio denominator, position type, acceleration rate, and

deceleration rate for the slave axis to operate. For the master axis, you can specify the command posi-

tion, actual position, or most recent command position.

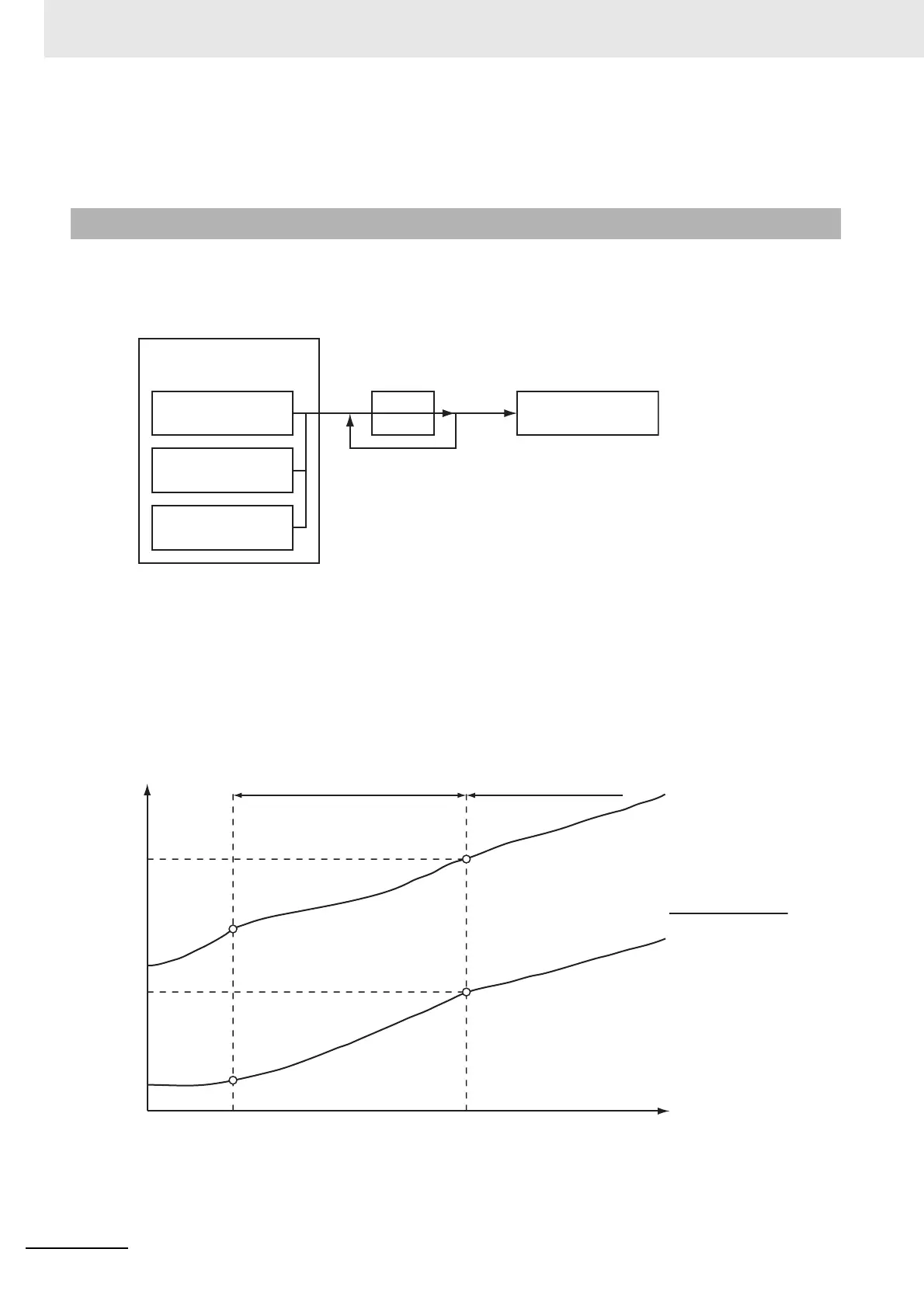

After operation starts, the slave axis uses the velocity of the master axis times the gear ratio for its tar-

get velocity, and accelerates/decelerates accordingly. The slave axis is in the catching phase until it

reaches the slave sync position. The slave axis enters the InSync phase after it reaches the slave sync

position. For either, the position of the slave axis is synchronized with the master axis. If the gear ratio

is positive, the slave axis and master axis move in the same direction. If the gear ratio is negative, the

slave axis and master axis move in the opposite directions. The following figure shows the operation

when the gear ratio is positive.

For details on positioning gear operation, refer to the MC_GearInPos (Positioning Gear Operation), the

MC_GearOut (End Gear Operation), and the MC_Stop instructions in the NJ/NX-series Motion Control

Instructions Reference Manual (Cat. No. W508).

9-2-3 Positioning Gear Operation

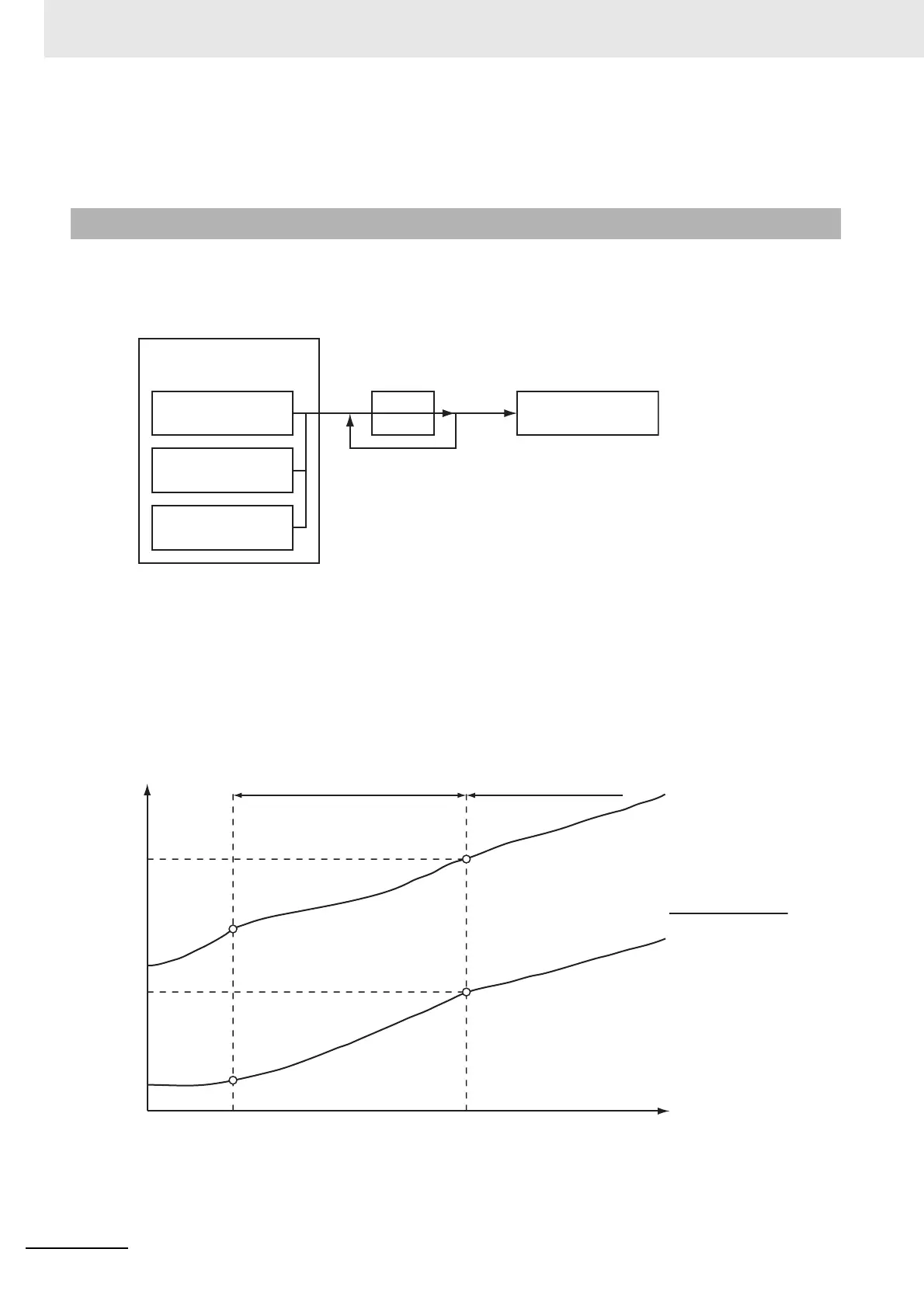

Command position

Remainder

Denominator

Numerator

Gear Operation

Most recent command

position

Command position

Actual position

Specify with

ReferenceType.

Execute

Catching Phase InSync phase

Master

Slave

RatioDenominator

RatioNumerator

Time

Travel distance of slave axis

= Travel distance of master axis ×

Position

Loading...

Loading...