9 Motion Control Functions

9-16

NJ/NX-series CPU Unit Motion Control User’s Manual (W507)

This section describes the cam tables that are used for cam operation.

9-2-5 Cam Tables

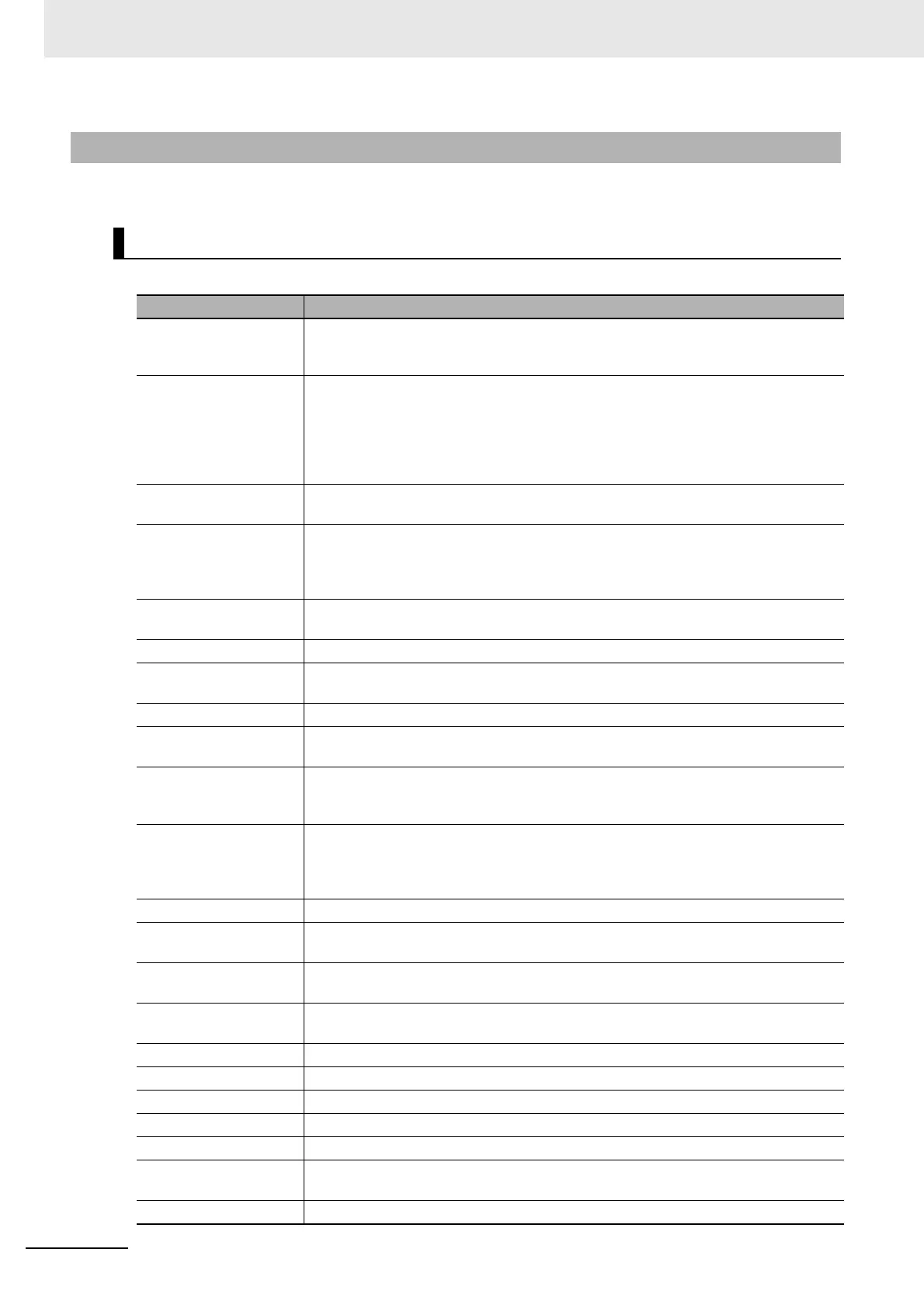

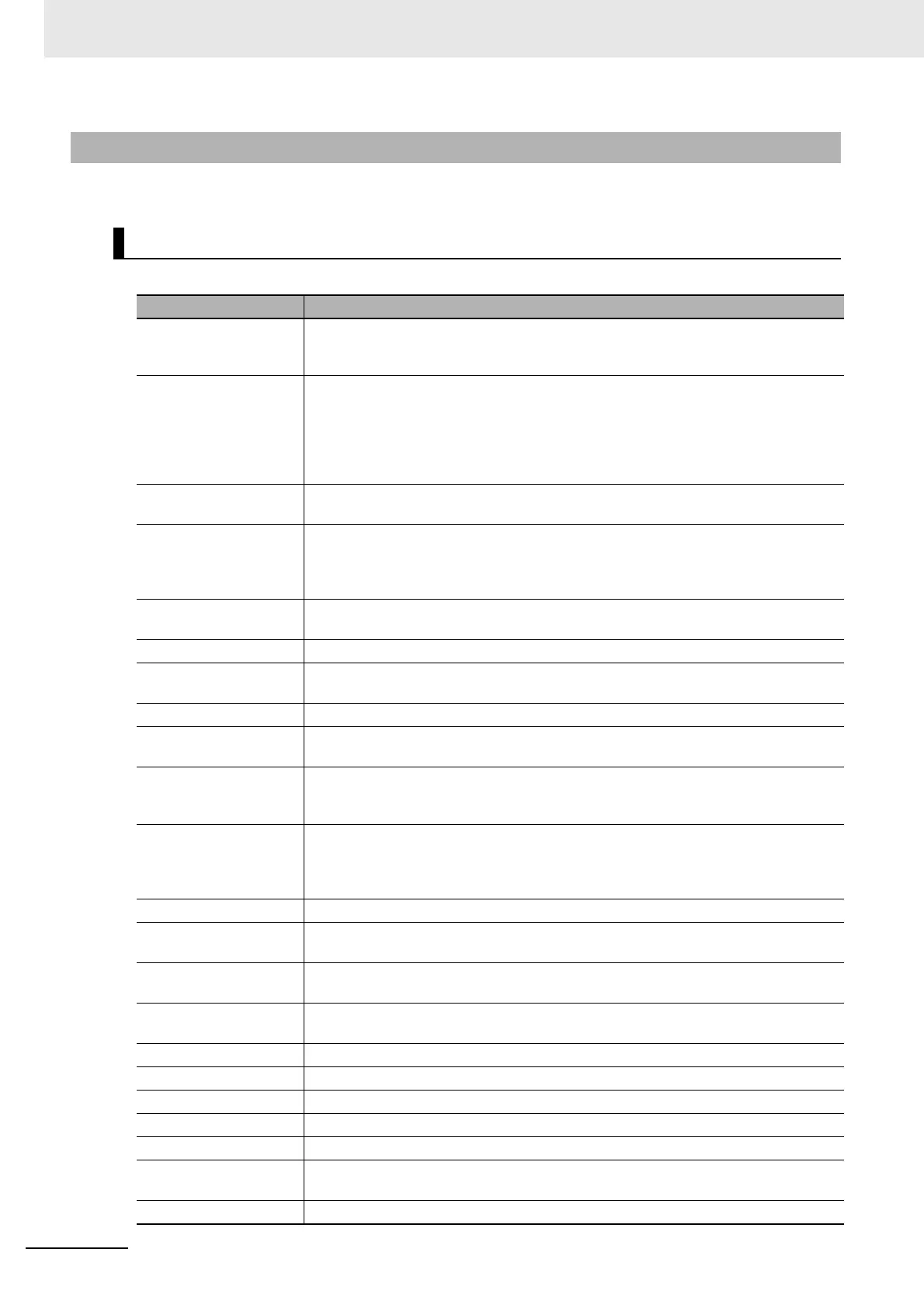

Cam Table Terminology

Term Description

cam operation An operation that takes one master axis and one slave axis and follows the cam pro-

file curve to derive the displacement of the slave axis from the phase of the master

axis.

cam profile curve A curve that shows the relationship between phases and displacements in a cam

operation.

The cam profile curve is created on the Sysmac Studio. You can use the cam profile

curve with a cam data variable after the cam profile curve is downloaded to the CPU

Unit. Use the Synchronization menu command of the Sysmac Studio to download the

project to the CPU Unit.

cam block You can select a cam curve in this block. It represents the area between the end point

of the previous cam block and the end point of the current cam block.

cam curve A curve that represents the cam characteristics. You can select a cam curve for each

cam block. The Sysmac Studio calculates the phase widths and displacement widths

from the specified points and creates the actual cam profile curve. You can choose

from different curves, such as straight line, parabolic, and trapecloid.

cam data Data made up of phases (master axis) and displacements (slave axis) for cam opera-

tion.

cam data variable A variable that represents the cam data as a structure array.

cam table A data table that contains cam data. If phase data is not in ascending order the cam

table is treated as an illegal cam table.

cam start point The first point in the cam data.

cam end point The last point of valid cam data in the cam data. If the cam end point is less than the

number of cam data, all phases and displacements after the cam end point will be 0.

cam block start point The start point for a cam block. It is the same as the cam start point at the start of the

cam operation. If the cam profile curve continues, this will be the same as the cam

block end point.

cam block end point The end point for a cam block. It is the same as the cam end point at the end of the

cam operation. If the cam profile curve continues, this will be the same as the cam

block start point. The cam block end point is defined as (horizontal axis, vertical axis)

= (phase end point, displacement end point).

original cam data Cam data that is created by dividing up the cam profile curve in the Cam Editor.

program-modified cam

data

The cam data changed by the user program while the CPU Unit is in operation.

master axis The axis that serves as the input to the cam operation. You can specify either Linear

Mode or Rotary Mode.

slave axis The axis that serves as the output from the cam operation. You can specify either Lin-

ear Mode or Rotary Mode.

phase The relative distance on the master axis from the start point of the cam table.

displacement The relative distance on the slave axis from the master following distance.

valid cam data The cam data other than the cam start point and other than data where the phase is 0.

invalid cam data The cam data other than the cam start point where the phase is 0.

number of valid cam data The number of sets of cam data.

maximum number of

cam data

The maximum number of sets of cam data that the cam table can contain.

cam data index The number of the cam data that is executed.

Loading...

Loading...