9-47

9 Motion Control Functions

NJ/NX-series CPU Unit Motion Control User’s Manual (W507)

9-5 Common Functions for Single-axis Control

9

9-5-7 Multi-execution of Motion Control Instructions (Buffer

Mode)

You can execute another motion control instruction while an axis is moving. In the PLCopen

®

technical

specifications, this functionality is defined as Buffer Mode, but in the MC Function Module this is some-

times referred to as multi-execution of instructions. You can use multi-execution of instructions to exe-

cute multiple motion control instructions in sequence without stopping the overall motion.

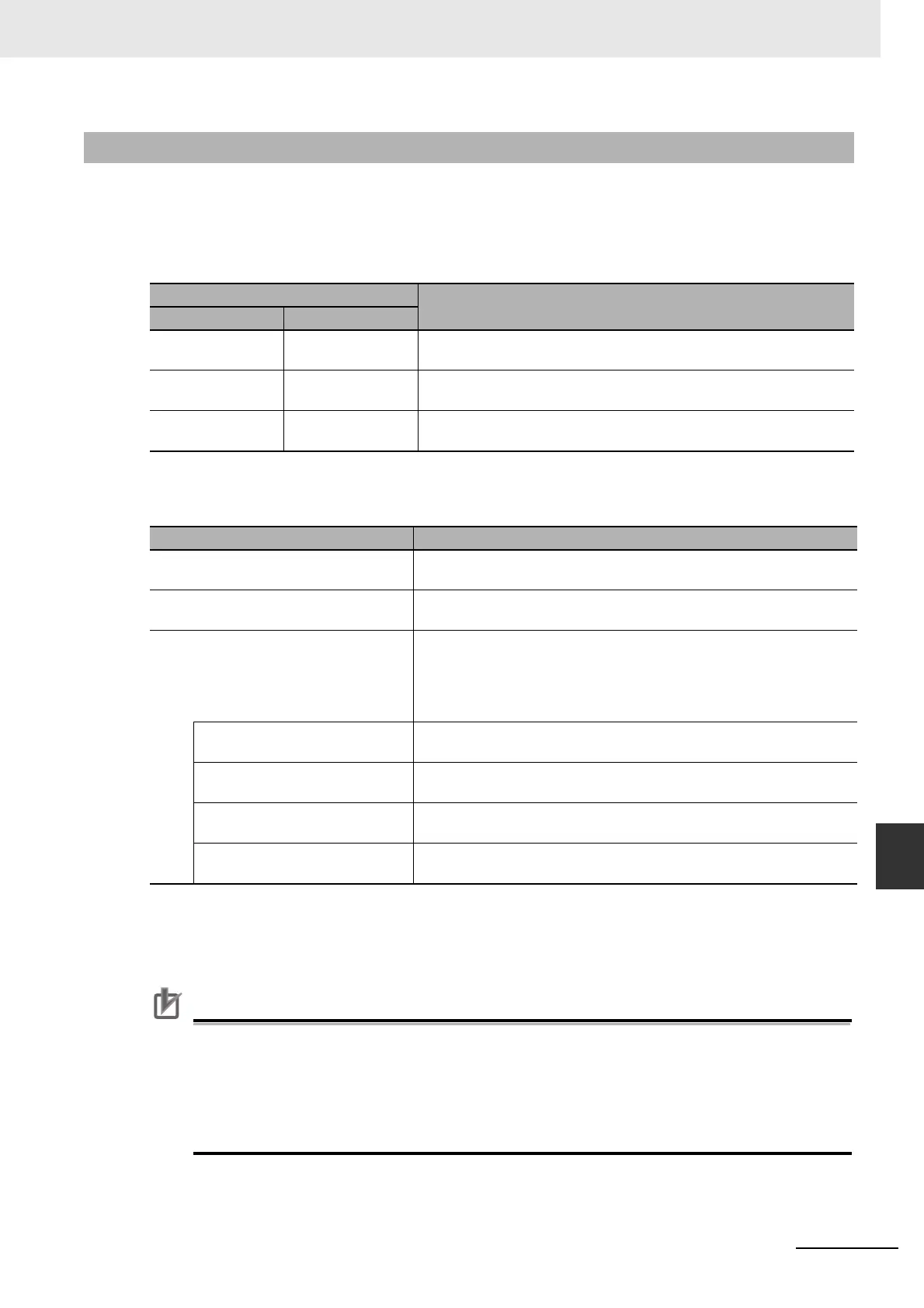

The following terms are used in relation to multi-execution of instructions in the MC Function Module.

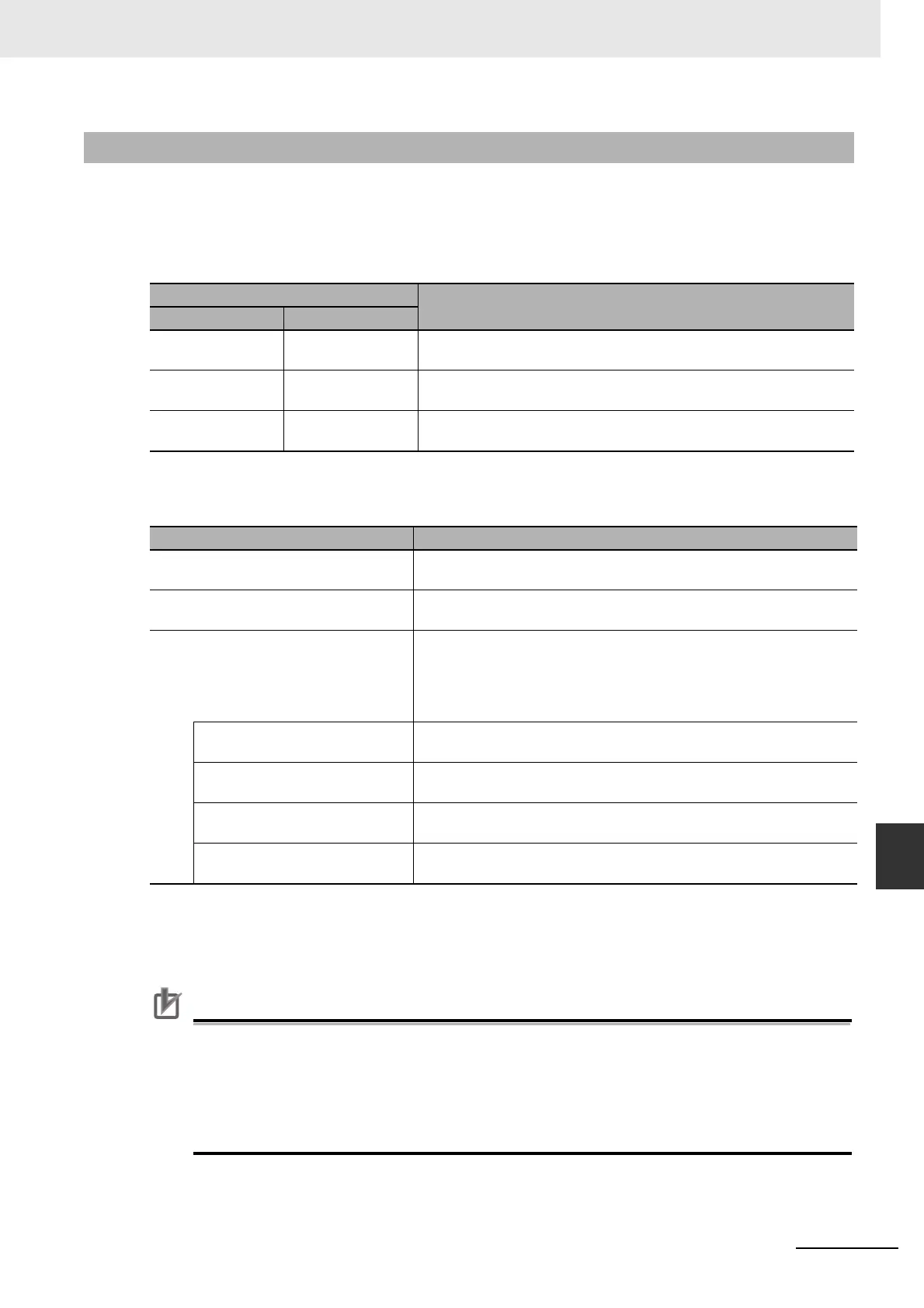

You can set the BufferMode (Buffer Mode Selection) input variable to motion control instruction to

select one of the following Buffer Modes. The main difference between these modes is the timing at

which the buffered instructions are executed and the transit velocity.

The multi-execution instruction is buffered in the MC Function Module and will be executed at the spec-

ified BufferMode timing and transit velocity for both buffered and blending modes. There is one buffer

for each axis. If aborting is specified, the instruction that was executed last is executed immediately, so

it is not buffered.

Precautions for Correct UsePrecautions for Correct Use

• Only one multi-execution instruction is buffered for each axis. If multi-execution is performed

for two or more instructions, an instruction error will occur.

• Multi-execution of multi-axes coordinated control instructions (axes group instructions) is not

possible for axes operating as a single axis. Similarly, multi-execution of single-axis control

instructions is not possible for axes operating under multi-axes coordinated control (axes

group instructions). An instruction error will occur if these rules are broken.

9-5-7 Multi-execution of Motion Control Instructions (Buffer Mode)

Term

Meaning

This manual PLCopen

®

Current instruction Previous function

block

The motion control instruction that was in operation just before exe-

cuting the multi-execution instruction.

Buffered instruction Next function block A motion control instruction that was executed during an axis motion

and is waiting to be executed.

Transit velocity Blending When blending is specified, it specifies the command velocity to use

by the current instruction to move to the specified target position.

Buffer Mode Description of operation

Aborting The current instruction is aborted and the multi-executed instruction is

executed.

Buffered The buffered instruction is executed after the operation for the current

instruction is normally finished.

Blending The buffered instruction is executed after the target position of the cur-

rent instruction is reached. In this mode, no stop is performed between

the current instruction and the buffered instruction. You can select

from the following transit velocities for when the current instruction

reaches the target position.

Blending Low (low velocity) The transit velocity is set to the target velocity of the current instruction

or the buffered instruction, whichever is lowest.

Blending Previous (previous

velocity)

The target velocity of the current instruction is used as the transit

velocity.

Blending Next (next velocity) The target velocity of the buffered instruction is used as the transit

velocity.

Blending High (high velocity) The transit velocity is set to the target velocity of the current instruction

or the buffered instruction, whichever is highest.

Loading...

Loading...