<7. Startup>

7-2

IM 11M12G01-02EN 1sh Edition : Mar. 25, 2021-00

7.2 Checking Piping and Wiring Connections

Check that the piping and wiring connections have been properly completed in accordance with

Chapter

“4. Piping” and Chapter “5. Wiring”

7.3 Checking Valve Setup

Set up valves and associated components used in the analyzer system as follows:

(1) If a stop valve is used in the detector’s calibration gas inlet, fully close this valve.

(2) If instrument air is used as the reference gas, adjust the air-set secondary pressure so that

plus approx. 150 kPa when a check valve is used, maximum pressure rating is 300 kPa) is

completing the valve setup, be sure to tighten the lock nut.

NOTE

unit.

7.4 Supplying Power to the Converter

CAUTION

To avoid temperature changes around the detector, it is recommended that (rather than turning it

where it is used periodically.

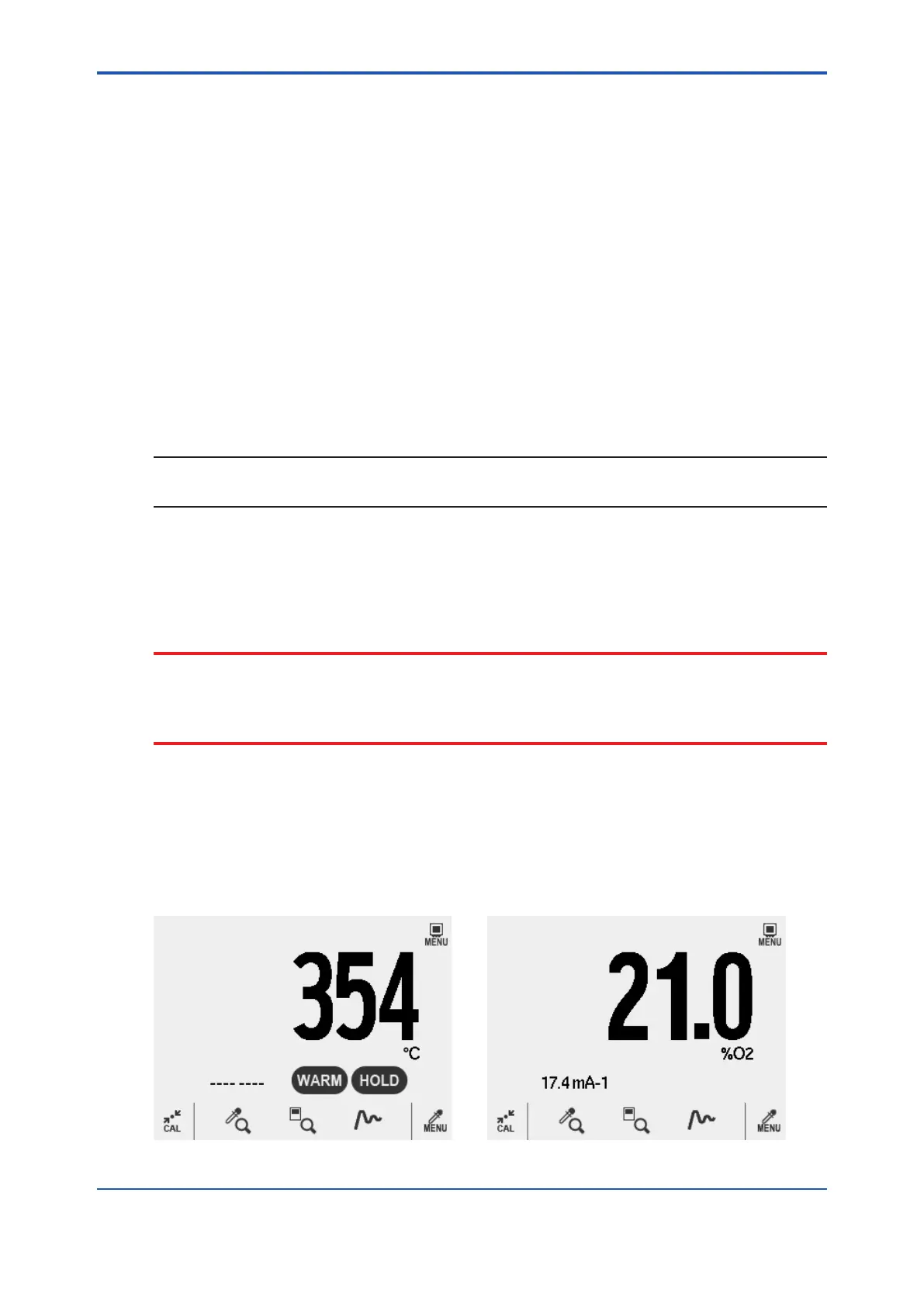

Supply power to the converter. A display as in Figure 7.2, which indicates the detector’s sensor

temperature, then appears. As the heat in the sensor increases, the temperature gradually rises

to 750°C. This takes about 20 minutes after the power is turned on, depending somewhat on the

ambient temperature and the sample gas temperature.

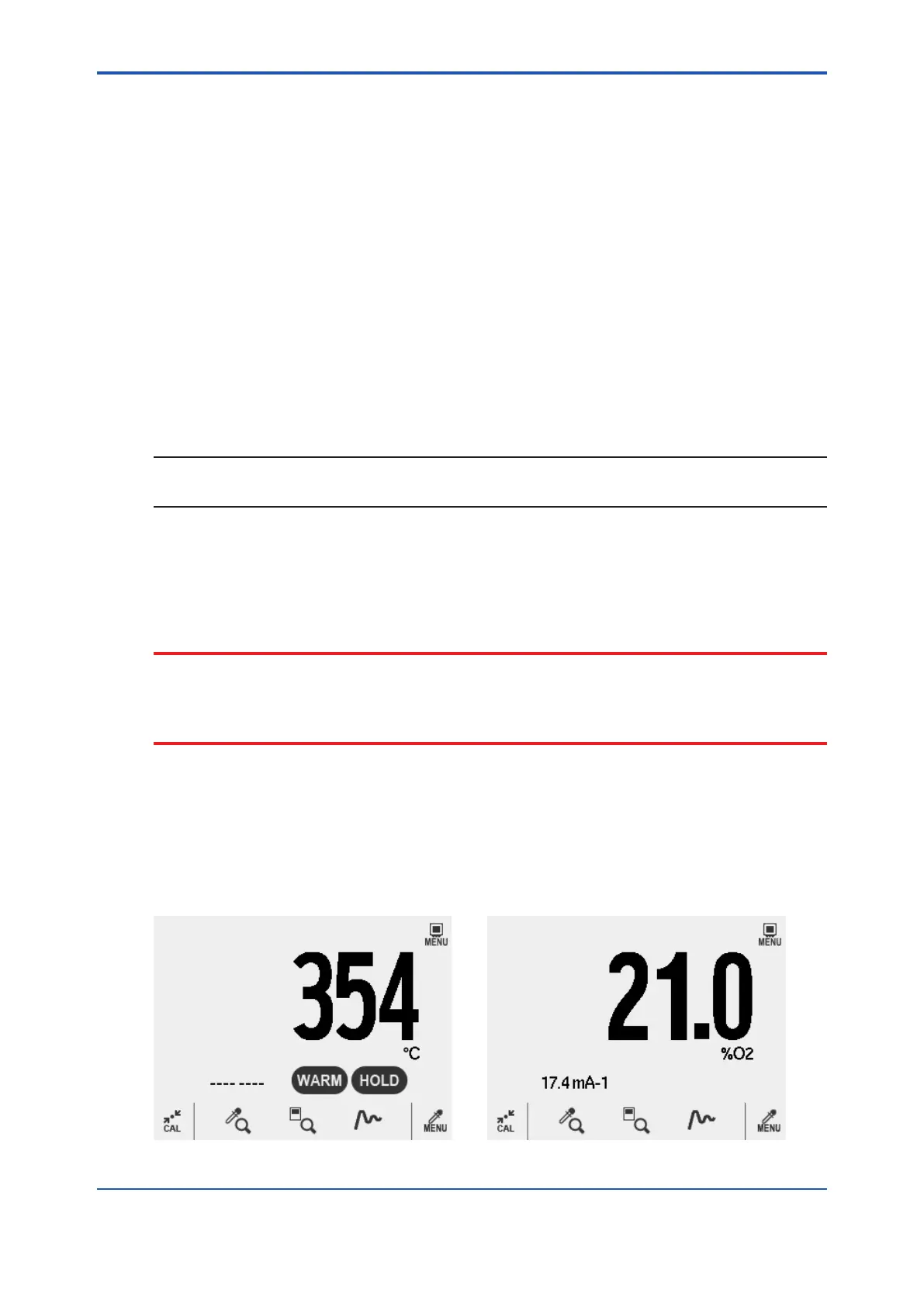

After the sensor temperature has stabilized at 750°C, the converter is in measurement mode.

The display panel then displays the oxygen concentration as in Figure 7.3. This is called Home

screen.

Figure 7.2 Display During Warm-up Figure 7.3 Measurement Mode Display

Loading...

Loading...