<11. Inspection and Maintenance>

11-2

IM 11M12G01-02EN 1sh Edition : Mar. 25, 2021-00

(4) Clean the U-shaped pipe. The pipe can be rinsed with water. However, it should be dried out

thoroughly before reassembly.

(5) Restore all components you removed for cleaning. Follow Section 11.1.3 to restore all

components in their original positions. Be sure to replace the O-ring(s) with new ones.

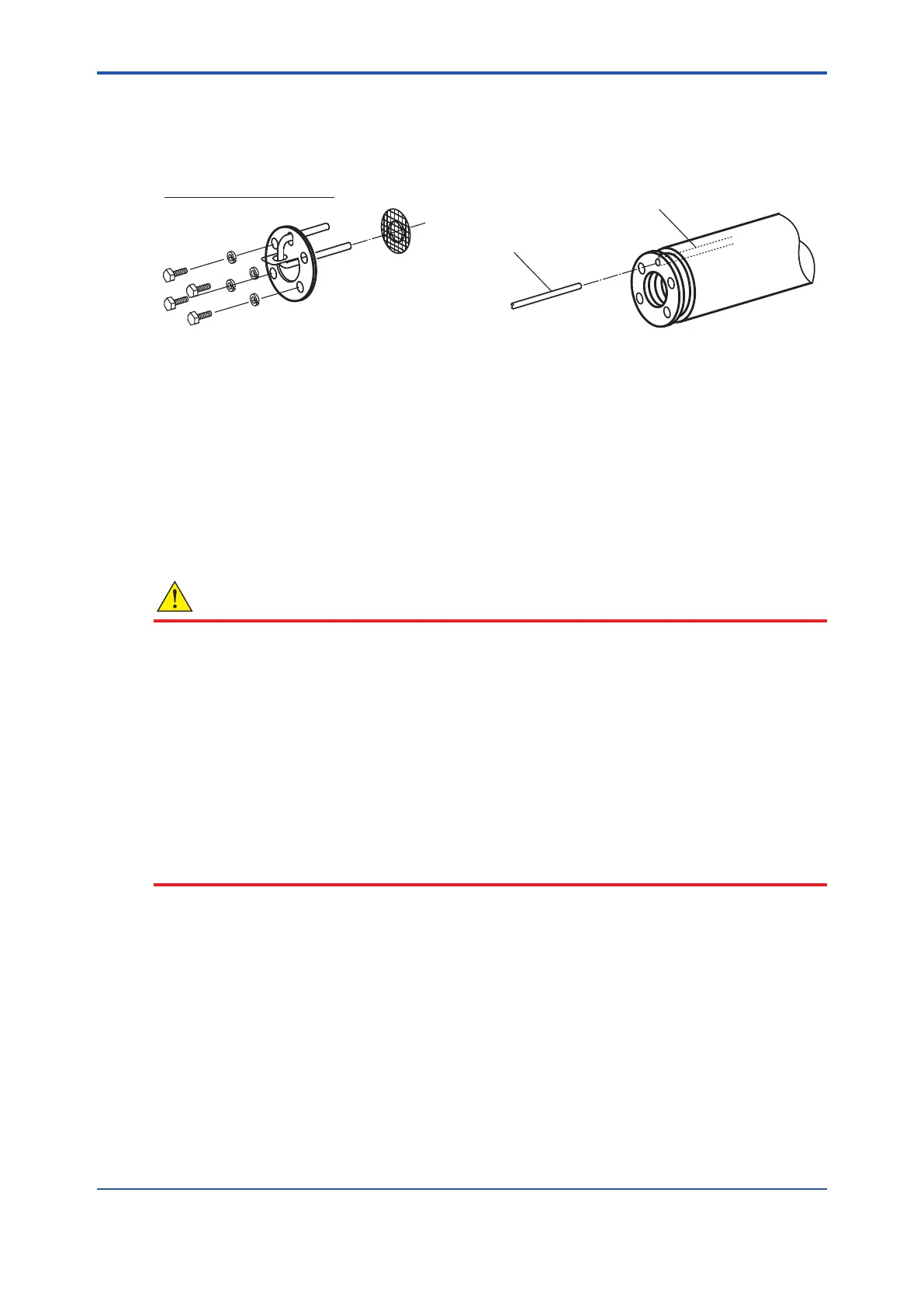

Calibration gas tube

Exploded view of components

Rod

(with outside diameter

of 2 to 2.5 mm)

Figure 11.1 Cleaning the Calibration Gas Tube

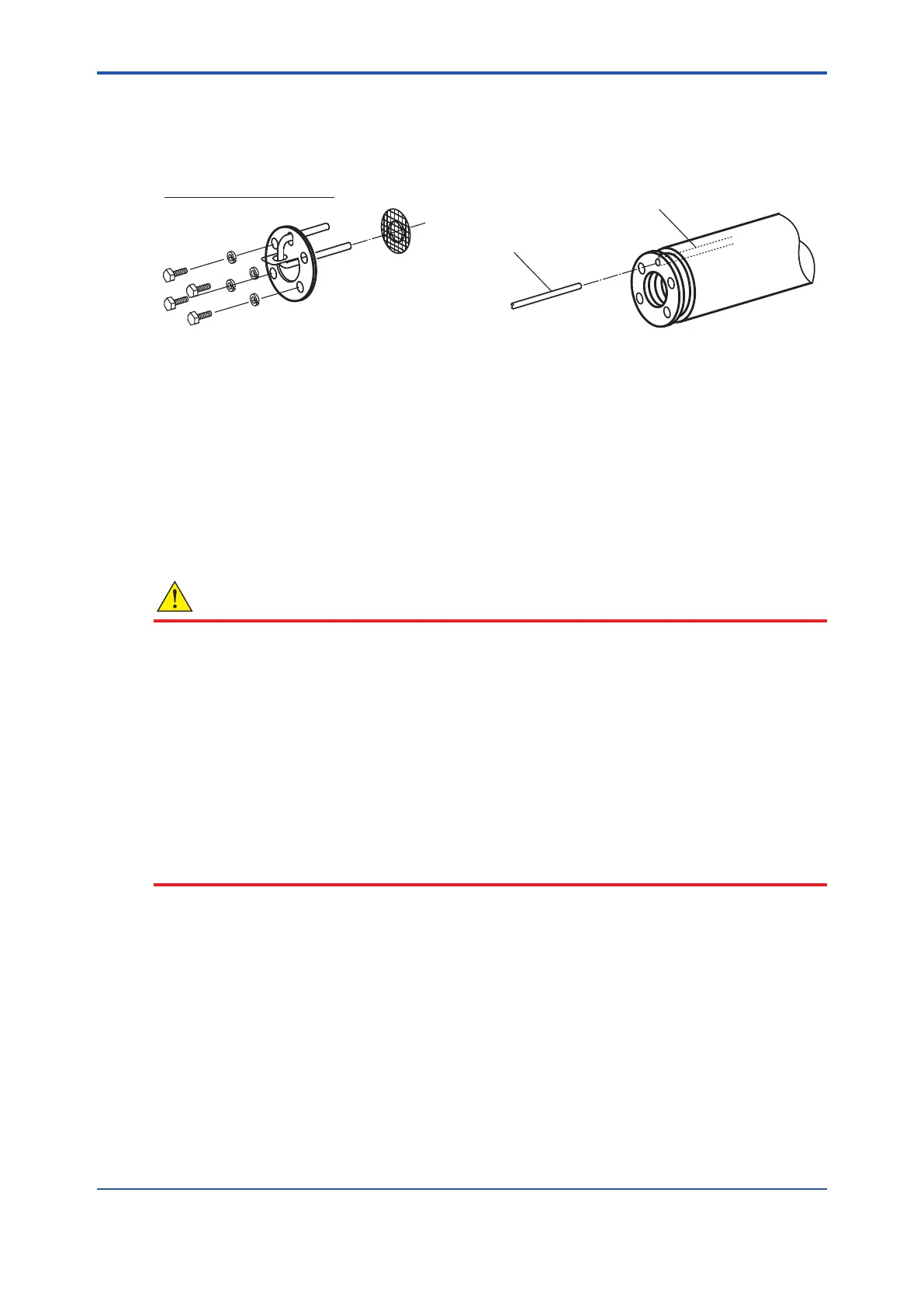

11.1.3 Replacing the Sensor Assembly

The performance of the sensor (cell) deteriorates as its surface becomes soiled during operation.

Therefore, you have to replace the sensor when its life expectancy expires, for example, when

it can no longer satisfy a zero gas ratio of 100 ± 30% or a span gas ratio of 0 ± 18%. In addition,

the sensor assembly is to be replaced if it becomes damaged and can no longer operate during

measurement.

If the sensor becomes no longer operable (for example, due to breakage), investigate the cause

and remedy the problem as much as possible to prevent recurrence.

CAUTION

• If the sensor assembly is to be replaced, allow enough time for the detector to cool down

from its high temperature. Otherwise, you may get burned.

• If the cell assembly is to be replaced, be sure to replace the metal O-ring and the contact

together.

Additionally, even in a case where the cell is not replaced, if the contact becomes deformed

and cannot make complete contact with the cell, replace the contact.

• If there is any corroded or discolored area in the metal O-ring groove in which the contact

is embedded, sand the groove with sandpaper or use a metal brush, and then sand further

with a higher grade of sandpaper (no. 1500 or so), or use an appropriate metal brush

to eliminate any sharp protrusions on the groove. The contact’s resistance should be

minimized.

• Use sensor assemblies manufactured in or after Sept. 2000: the serial number on the side

of the sensor assembly should be 0J000 or later (for example: 0K123, 1AA01 etc)

Loading...

Loading...