<4. Piping>

4-1

IM 11M12G01-02EN 1sh Edition : Mar. 25, 2021-00

4. Piping

Zirconia Oxygen/Humidity Analyzer.

• Ensure that each check valve, stop valve and joint used for piping do not allow leakage.

Especially, if there is any leakage of the calibration gas from pipes and joints, it may cause

clogging of the pipes or incorrect calibration.

• Be sure to conduct leakage test after piping.

removing any dust, oil mist and the like) for the reference gas.

• When the instrument uses natural convection for reference gas, ambient air near the

ambient humidity changes or the like. If more accurate analysis is necessary, use instrument

like) for reference gas.

Stable analyzing can be conducted when using instrument air.

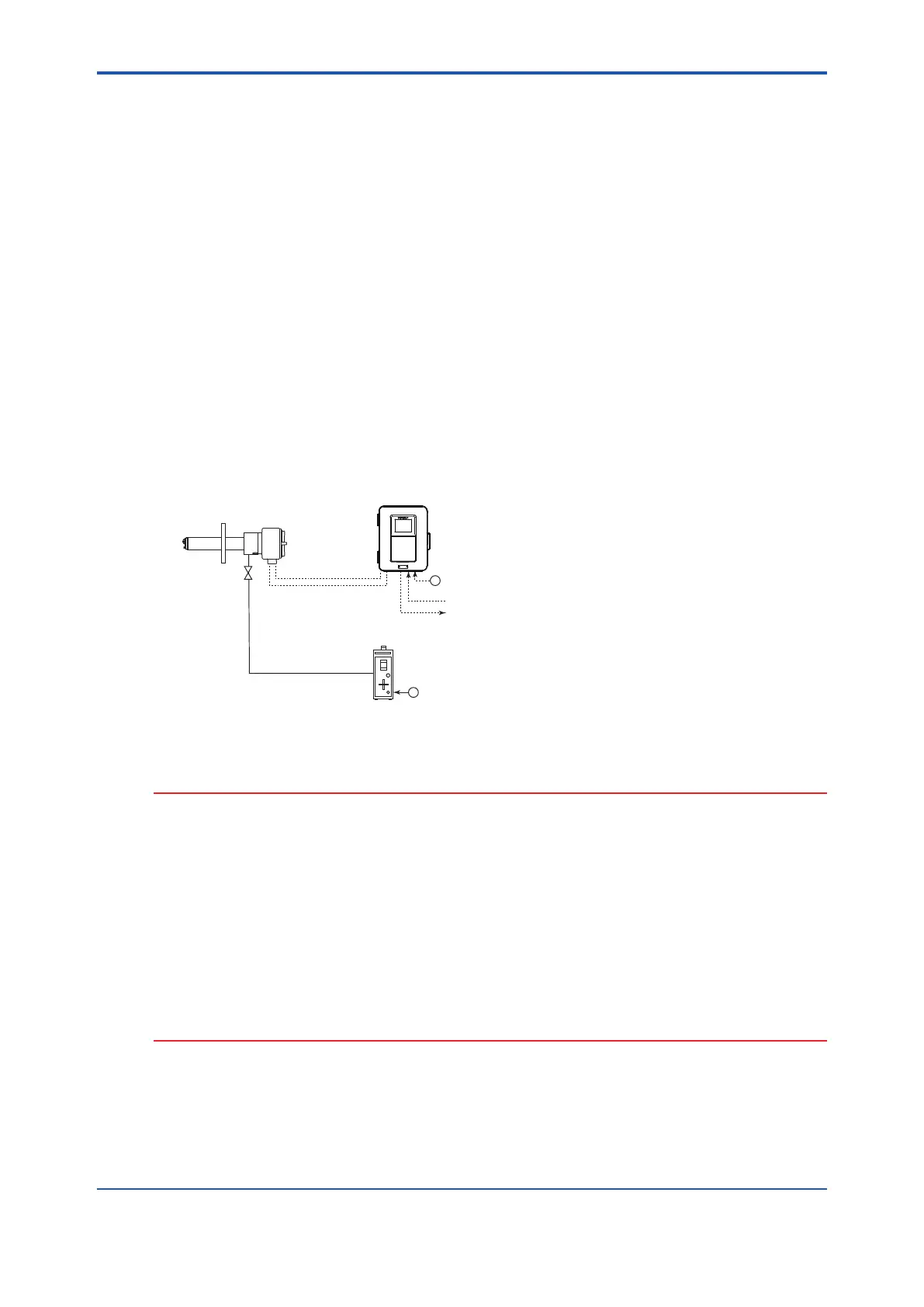

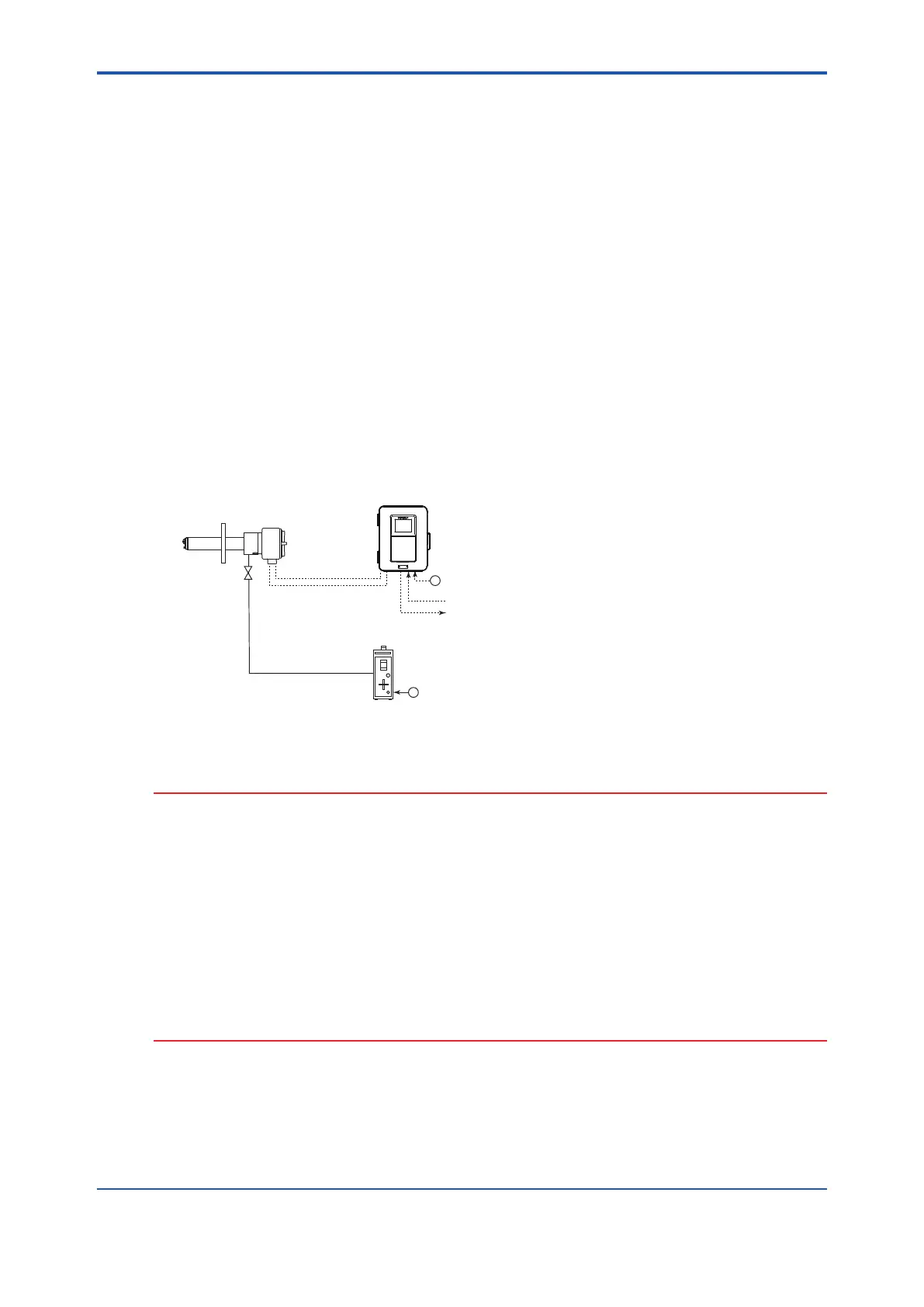

4.1 Piping for System 1

The piping in System 1 is illustrated in Figure 4.1.

~

~

ZO21S Standard gas unit

ZR22G Separate type

Zirconia Oxygen/Humidity Analyzer, Detector

ZR802G Zirconia Oxygen/Humidity Analyzer,

Explosion-proof Converter

Stop valve

Calibration gas

100 to

240 V AC

100/110/115/200/220/240 V AC

Contact input

Analog output, Contact output

Digital output (HART)

Signal

(6-core shield cable)

Heater (2-core)

Figure 4.1 Piping in System 1

CAUTION

• The stop valve should be connected directly to the detector. If any piping is present between

the detector and the stop valve, water may condense in the pipe, which may cause damage

to the detector by rapid cooling when the calibration gas is introduced.

The stop valve should be closed except while the calibration gas is being introduced.

• If a high temperature detector is used (the sample gas temperature is 700°C or higher),

the detector is not clean.

• The reference gas should have an oxygen concentration identical to that of fresh air (21%).

• When a high temperature detector is used, the sample gas is vented into the surrounding

air.

is installed.

Piping in System 1 is as follows:

• Connect a stop valve to the nipple at the calibration gas inlet of the detector. Then mount

a joint for a 6 mm (O.D.) x 4 mm (I.D.) soft tube at the stop valve connection hole of the

inlet side (see Section

“4.1.2 Connection to the Calibration Gas Inlet”). The tube is to

be connected to this joint only during calibration.

Loading...

Loading...