<7. Startup>

7-13

IM 11M12G01-02EN

CAUTION

• If instrument air is used for the span gas, dehumidify to a dew point of -20°C or less to

remove oil mist and dust before use.

7.12.2 Manual Calibration

Preparing for calibration Implementation

setting valve is fully closed. Open the zero gas cylinder pressure reducing valve so that the

approx. 150 kPa when a check valve is used, maximum pressure rating is 300 kPa).

ZH40H Automatic calibration unit can perform manual calibration in the same way. ZR40H valves

(solenoid valve) open and close in conjunction with screen.

Calibration operating instructions assume that the same instrumentation air as the reference gas

is used as the span gas

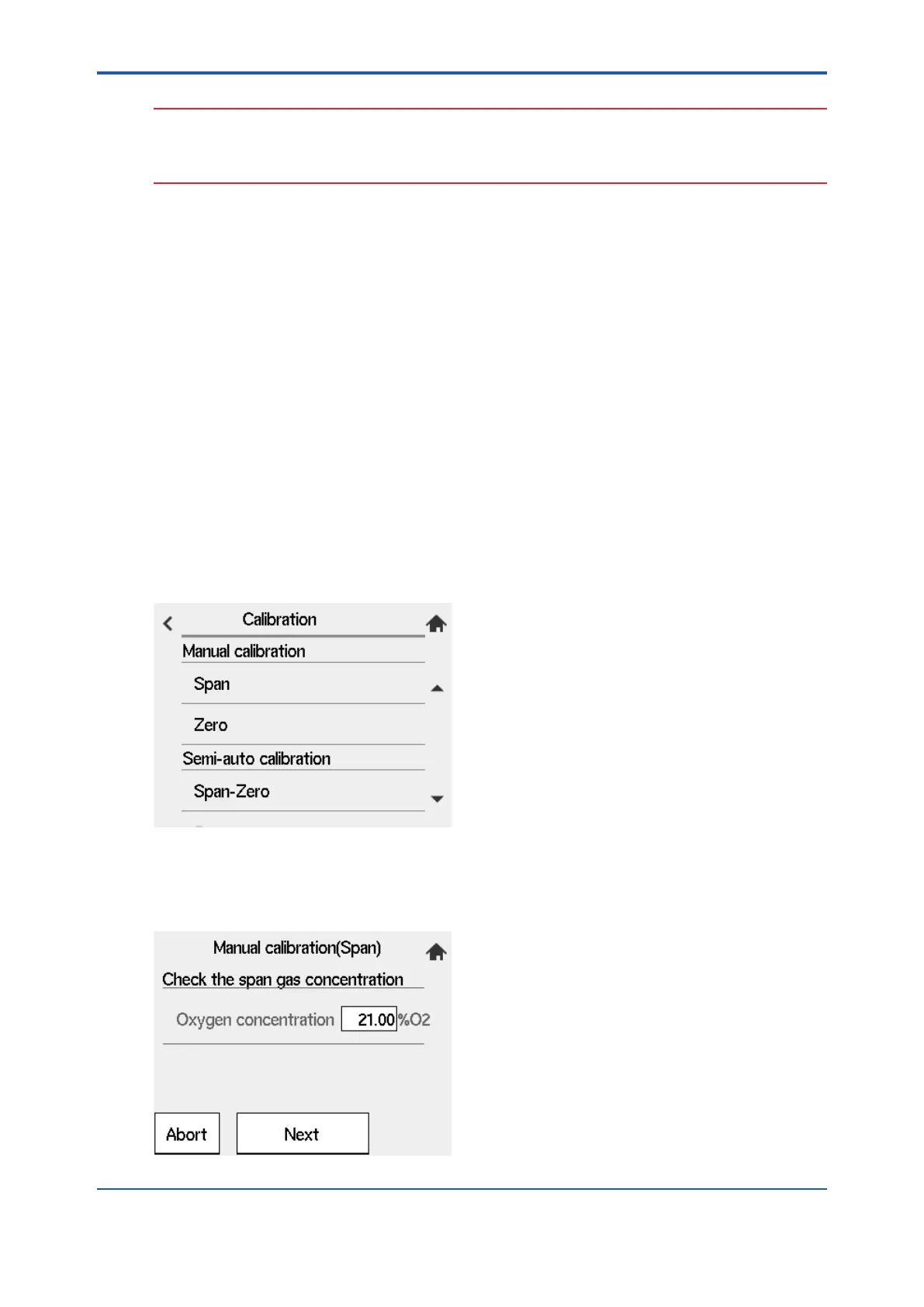

(1) Home screen > “Calibration” > “Manual calibration” “Span”

n Calibration Procedures

This manual assumes that the instrument air is the same as the reference gas used for the span

gas. Follow the steps below to conduct manual calibration:

(1) Press the [Setup] key in the Basic panel display to display the Execution/Setup display.

Then select “Calibration” in the Execution/Setup display.

Figure 7.15 Manual calibration steps

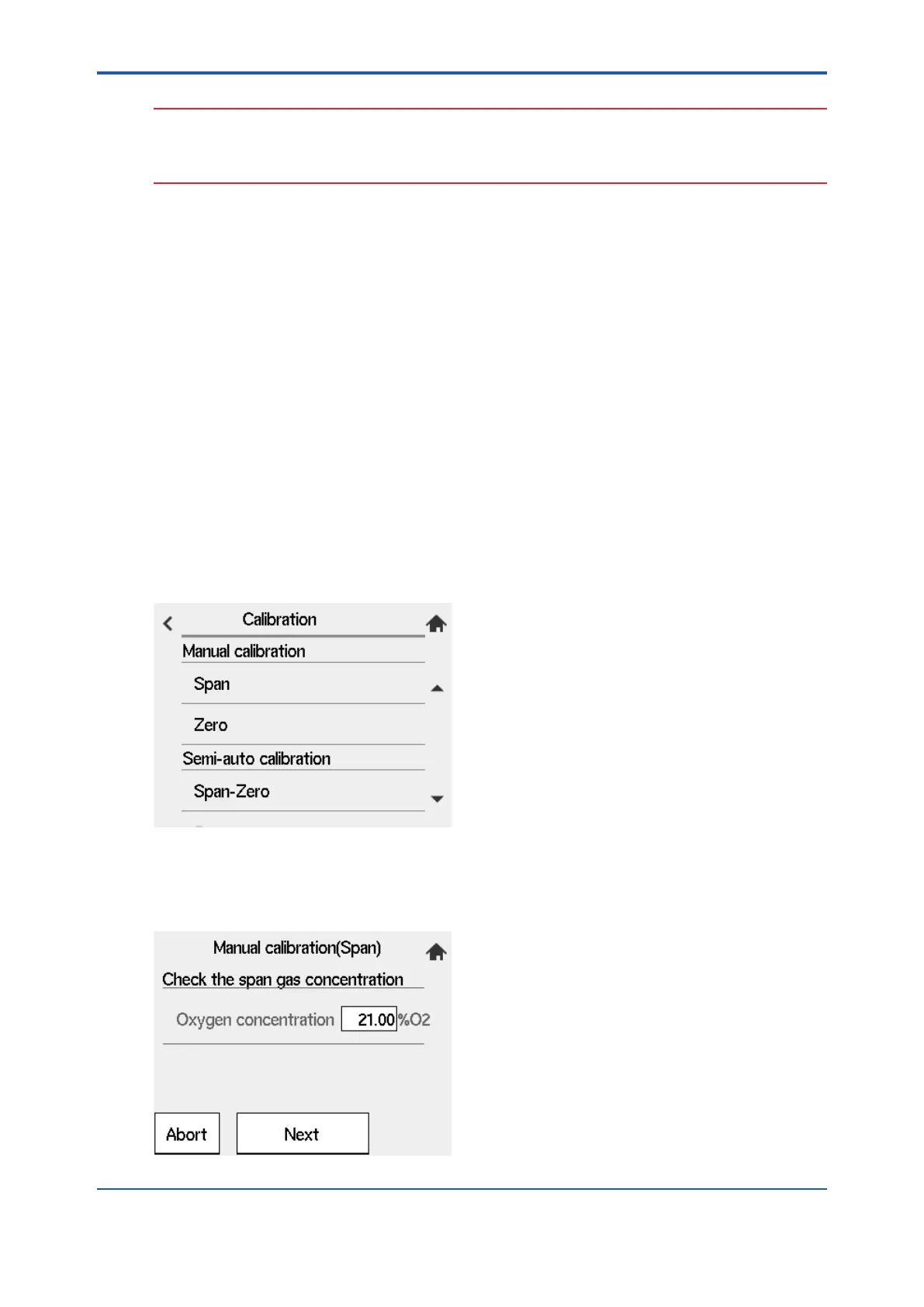

(2) When "Span" is selected, screen of the span gas concentration is displayed. Check that the

oxygen concentration value of the span gas on screen matches the oxygen concentration

value of calibration gas to be actually used, and then select "Next"

Figure 7.16 Span gas concentration check

1sh Edition : Mar. 25, 2021-00

Loading...

Loading...