<4. Piping>

4-3

IM 11M12G01-02EN 1sh Edition : Mar. 25, 2021-00

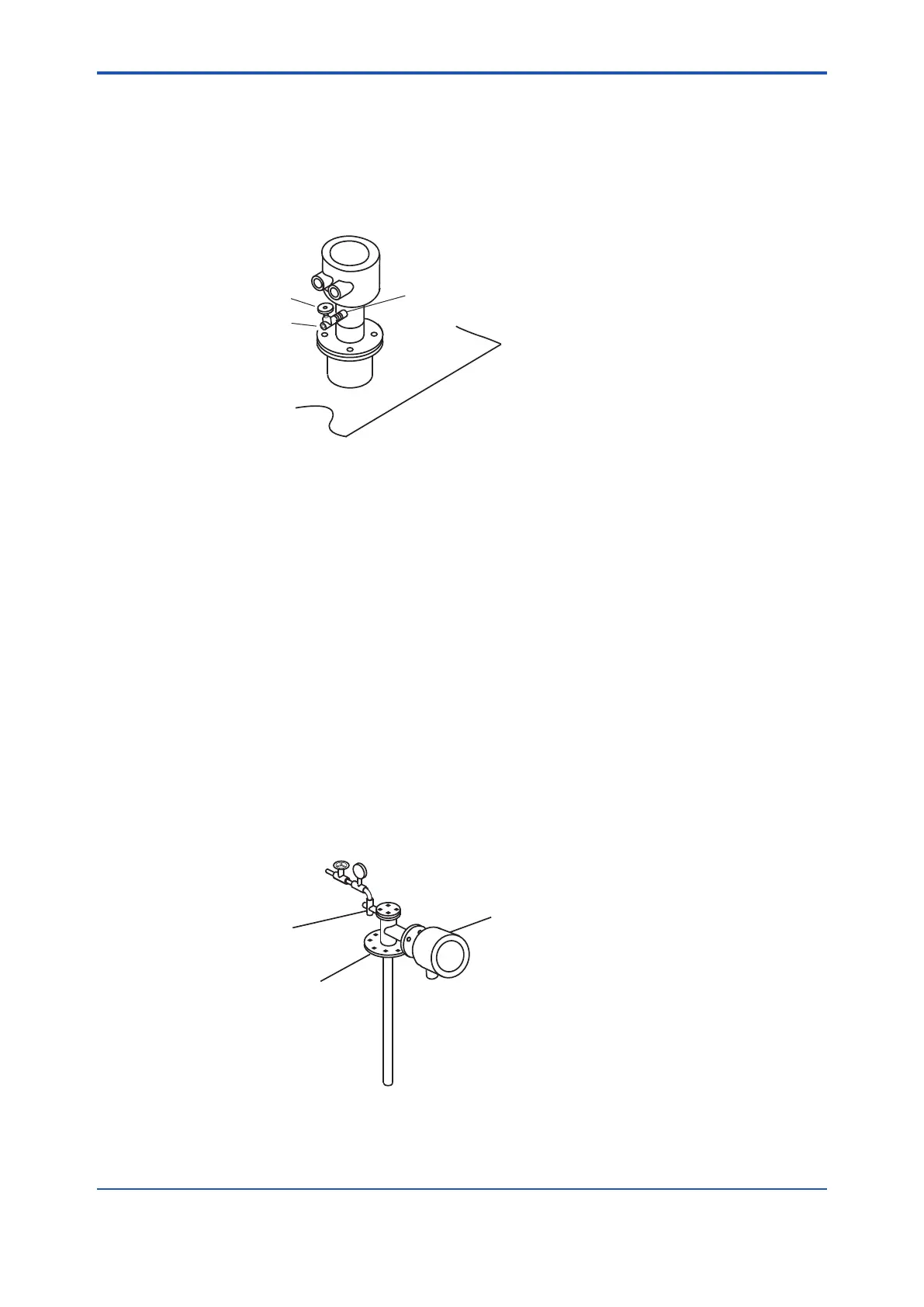

4.1.2 Connection to the Calibration Gas Inlet

When carrying out calibration, connect the piping (6(O.D) ~4(I.D.) mm tube) from the standard

by YOKOGAWA) on a nipple (found on the local market) as illustrated in Figure 4.2, and mount a

joint (also found on the local market) at the stop valve tip. (The stop valve may be mounted on the

detector prior to shipping the detector.)

Note: Mount the stop valve close to the detector.

F4-2E.ai

NippleStop valve

Tube connection joint

Figure 4.2 Connection to the calibration gas inlet

4.1.3 Connection to the Reference Gas Inlet

convection for the reference gas (models ZR22G----C). Leave the plug as it is . If the

air around the detector is polluted and the necessary oxygen concentration (21 vol%O

2

)

cannot be obtained, prepare piping the same as which described in Section 4.2, System 2.

described in Section 4.2, System 2 (models ZR22G----E or P).

4.1.4 Piping to the High Temperature Probe Adapter

• The sample gas should be at a temperature below 700°C before reaching the detector

sensor. If the gas is under negative pressure, it should be fed to the detector by suction.

•

For usage of the probe adapter when using high temperature detector, refer to Section “3.2.1

Usage of the High Temperature Probe Adapter (ZO21P-H)”.

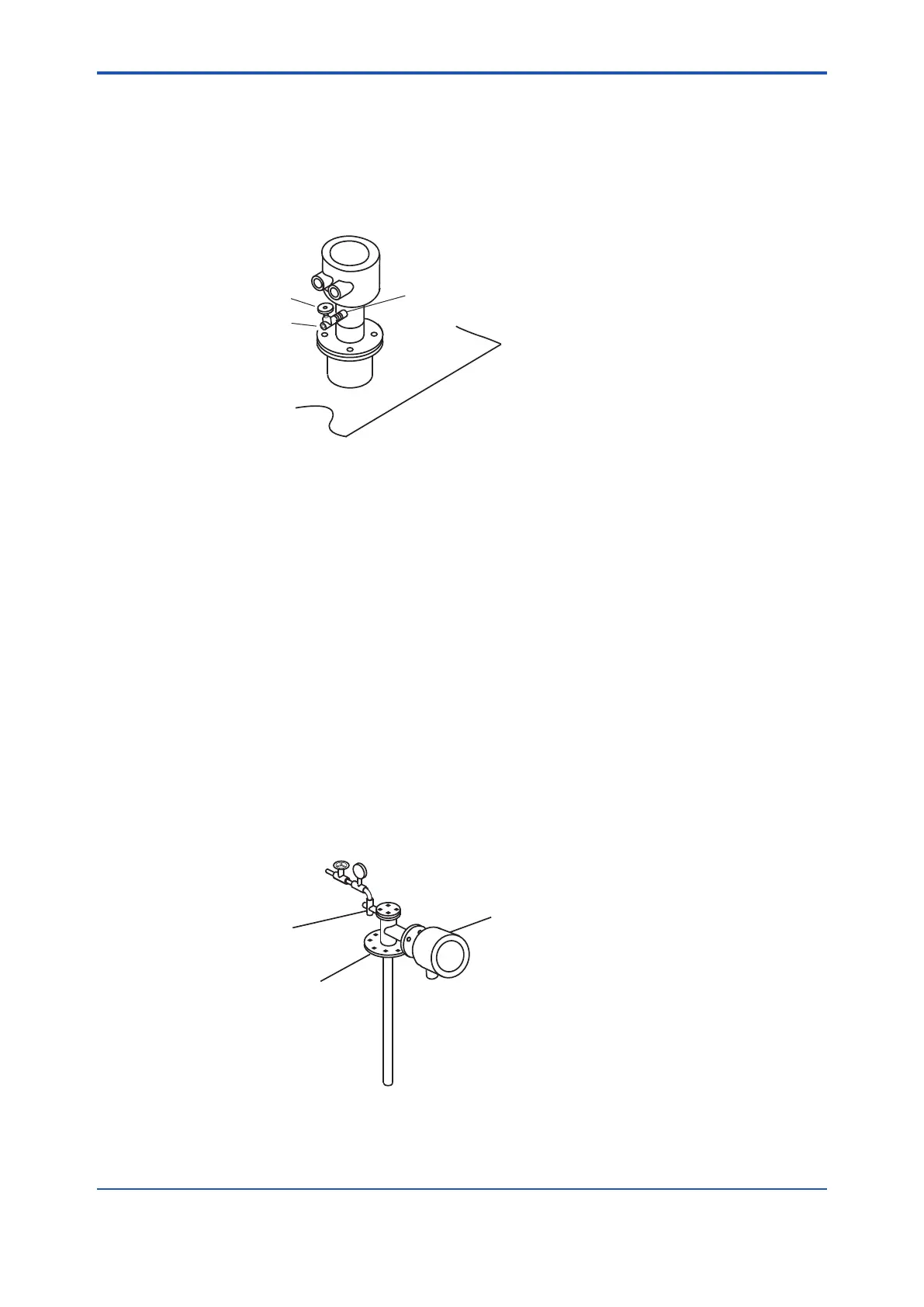

• If the sample gas is under negative pressure, connect the ejector assembly (E7046EC/

E7046EN) as illustrated in Figure 4.3. Mount the pressure gauge as close as possible to

the ejector assembly. However, if the ambient temperature is too high, mount the gauge in a

location with a temperature below 40°C.

Ejector assembly for

high temperature use

Adapter for

high temperature probe

Detector

F4-3E.ai

Figure 4.3 Mounting the ejector assembly

kPa, the sample gas temperature may not be below 700°C at the detector.

Loading...

Loading...