<4. Piping>

4-11

IM 11M12G01-02EN 1sh Edition : Mar. 25, 2021-00

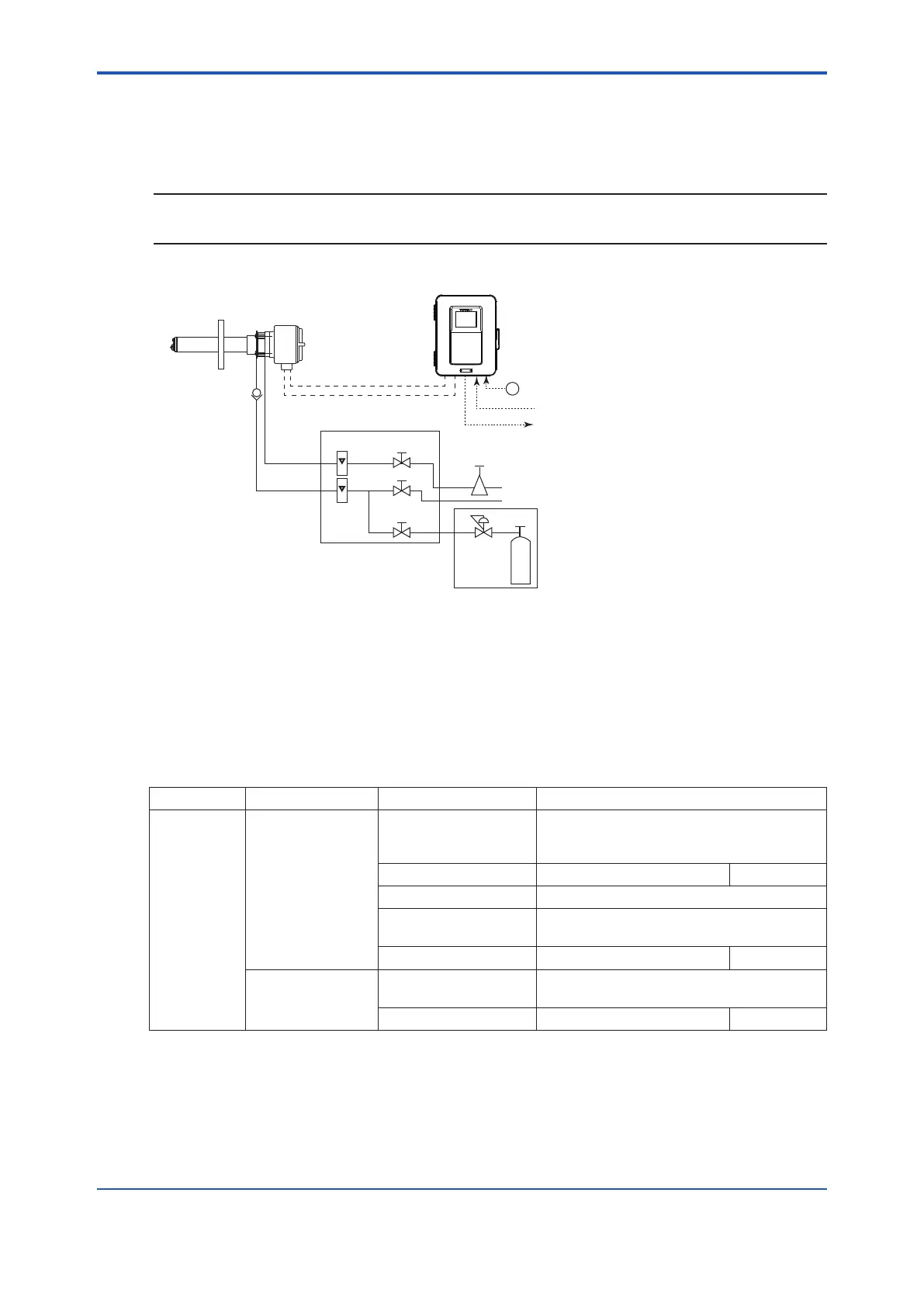

Figure 4.14 illustrates an example of System 2 using a detector with pressure compensation.

NOTE

When using the ZA8F Flow Setting Unit and ZR40H Automatic Calibration Unit, please note that

~

ZA8F Flow Setting Unit

ZR22G Separate type

Zirconia Oxygen Analyzer, Detector

ZR802G Converter

Reference

gas

Calibration

gas

Stop valve

or

Check valve

Needle

valve

Flowmeter

Instrument air

Air Set

Pressure

reducing

valve

Zero gas cylinder

Calibration gas

unit case

Span gas

(Same as Zero gas calibration unit)

100 to

240 V AC

Contact input

Analog output, Contact output

Digital output (HART)

Signal

(6-core shield cable)

Heater (2 core cable)

Figure 4.14 System 2 using a detector with pressure compensation

4.4.1 Piping Parts for a System using Detector with

Pressure Compensation

Check that the parts listed in Table 4.3 are ready.

Table 4.3 Piping Parts

Detector Piping location Parts Name Note

Detector with

pressure

compensation

Calibration gas inlet Stop valve or check

valve

Recommended by YOKOGAWA (L9852CB

or G7016XH) Provided by YOKOGAWA

(K9292DN or K9292DS)

Nipple * Rc 1/4 or 1/4 NPT General parts

Zero gas cylinder User´s scope

Pressure reducing valve Recommended by YOKOGAWA

(G7013XF or G7014XF)

Joint for tube connection Rc 1/4 or 1/4 NPT General parts

Reference gas inlet Air set Recommended by YOKOGAWA

(G7003XF/K9473XK or G7004XF/K9473XG)

Joint for tube connection Rc 1/4 or 1/4 NPT General parts

General parts can be found on the local market.

4.4.2 Piping for the Calibration Gas

Calibration gas piping is basically identical to that of System 2. See Section “4.2.2 Piping

for the Calibration Gas”.

Loading...

Loading...