● After cutting the valve seat, apply lapping compound to

the valve face, and insert the valve with a valve guide

reamer.

NOTE

·Do not excessively press and turn the valve to set it as it

may cause damage. Gently strike and set the valve.

·The seat surface may become worn on one side if the

valve is set in the same position. Turn the valve slightly

when setting it.

·Take precautions not to allow compound to get into the

clearance between the stem and guide while the valve

is being set.

CYLINDER HEAD ASSEMBLY

● Install new stem seals.

NOTE

·Replace the stem seals with new ones whenever a stem

seal is removed.

● Lubricate each valve stem with molybdenum disulfide

grease and insert the valve into the valve guide.

CAUTION

·Turning a valve too fast can damage the stem seals.

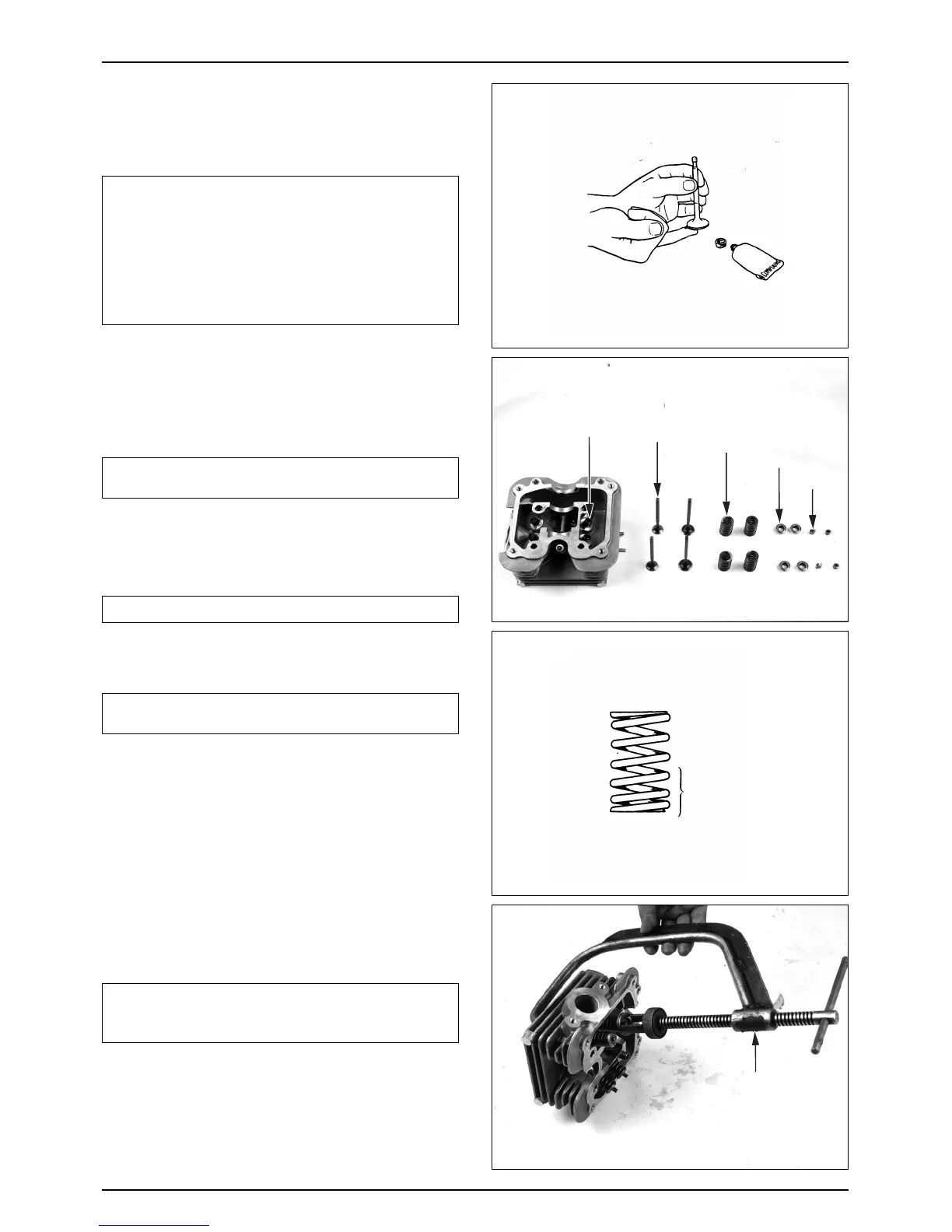

● Install the spring seats, valve springs and retainers.

NOTE

·For valve spring with varying pitch, install the valve

springs with the narrow pitch end facing down.

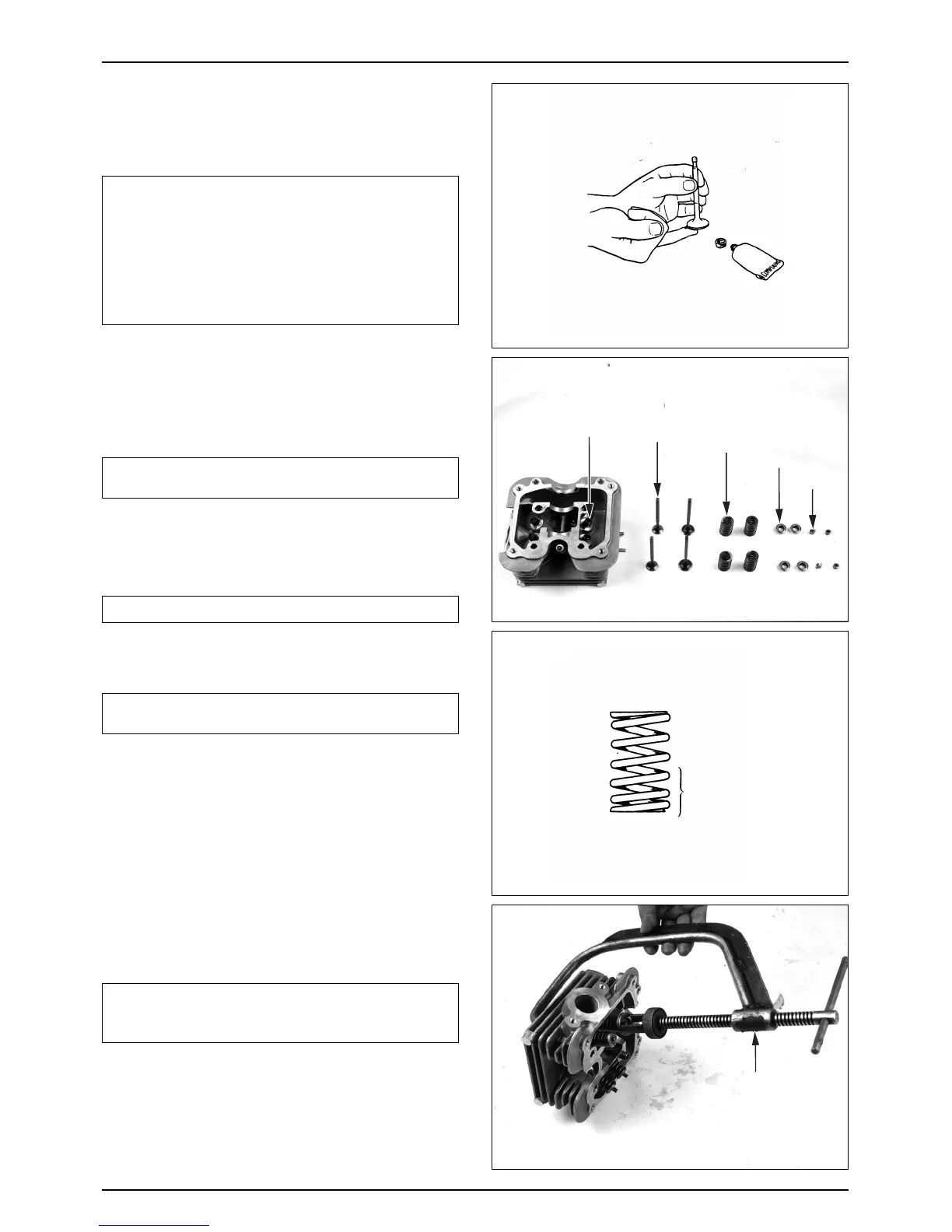

● Compress the valve springs with the valve spring

compressor and install the valve cotters.

CAUTION

·Compressing the valve spring more than necessary

when installing the valve cotters may cause loss of

valve spring tension.

TOOL : VALVE SPRING COMPRESSOR

9-11

CYLINDER HEAD / VALVES

Loading...

Loading...