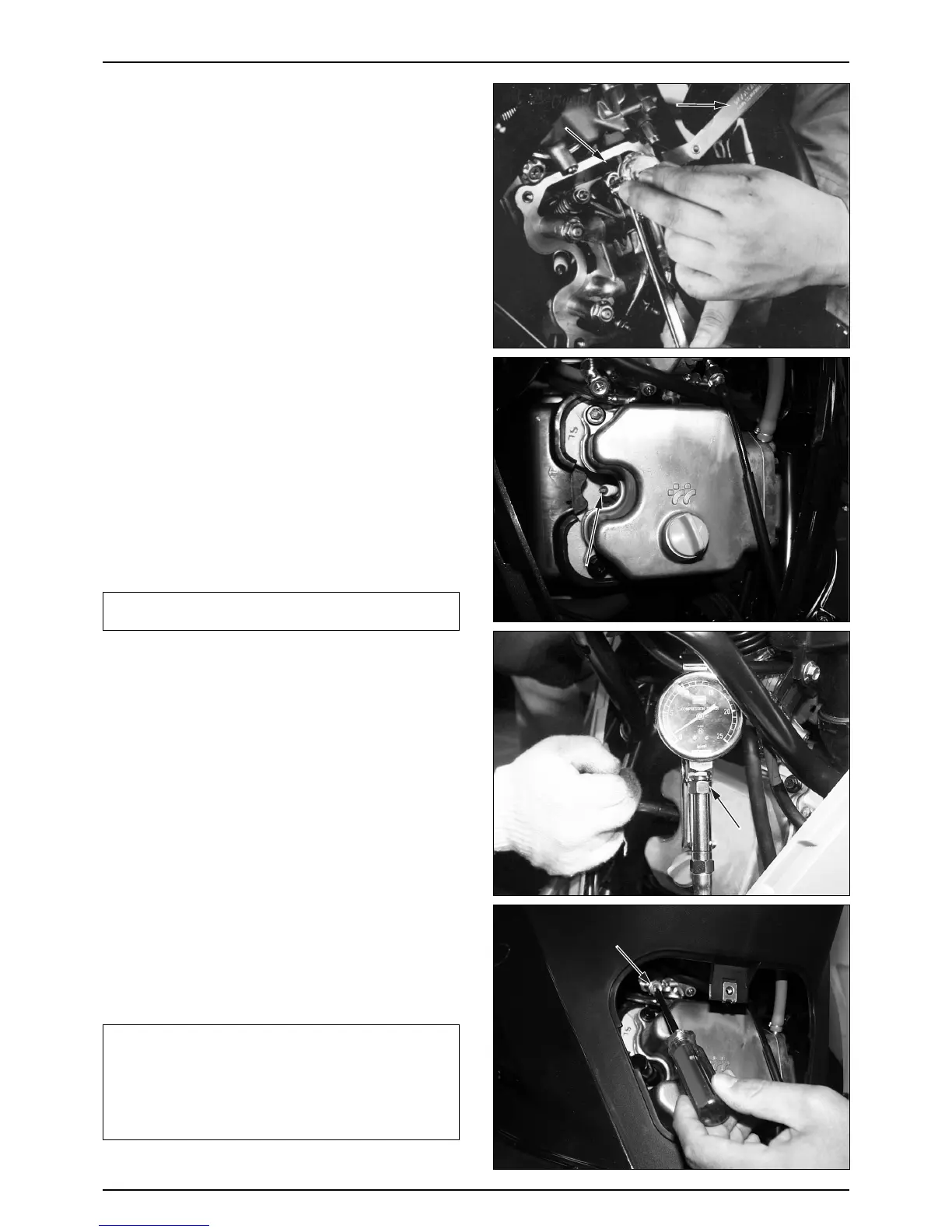

● Loosen the lock nut with a valve wrench, and set valve

clearance to a prescribed level by turning the adjusting

screw with a valve adjusting wrench.

● After setting clearance to the prescribed level, hold the

adjuster screw with a valve adjusting wrench, and

tighten the lock nut.

TORQUE VALUES : 1.1kgf

·

m

TOOLS : WRENCH 8X9mm

ADJUSTING WRENCH B

FEELER GAUGE

● Measure the valve clearance again.

● Install the cylinder head cover and tighten the bolts.

TORQUE VALUES : 1.0 kgf

·

m

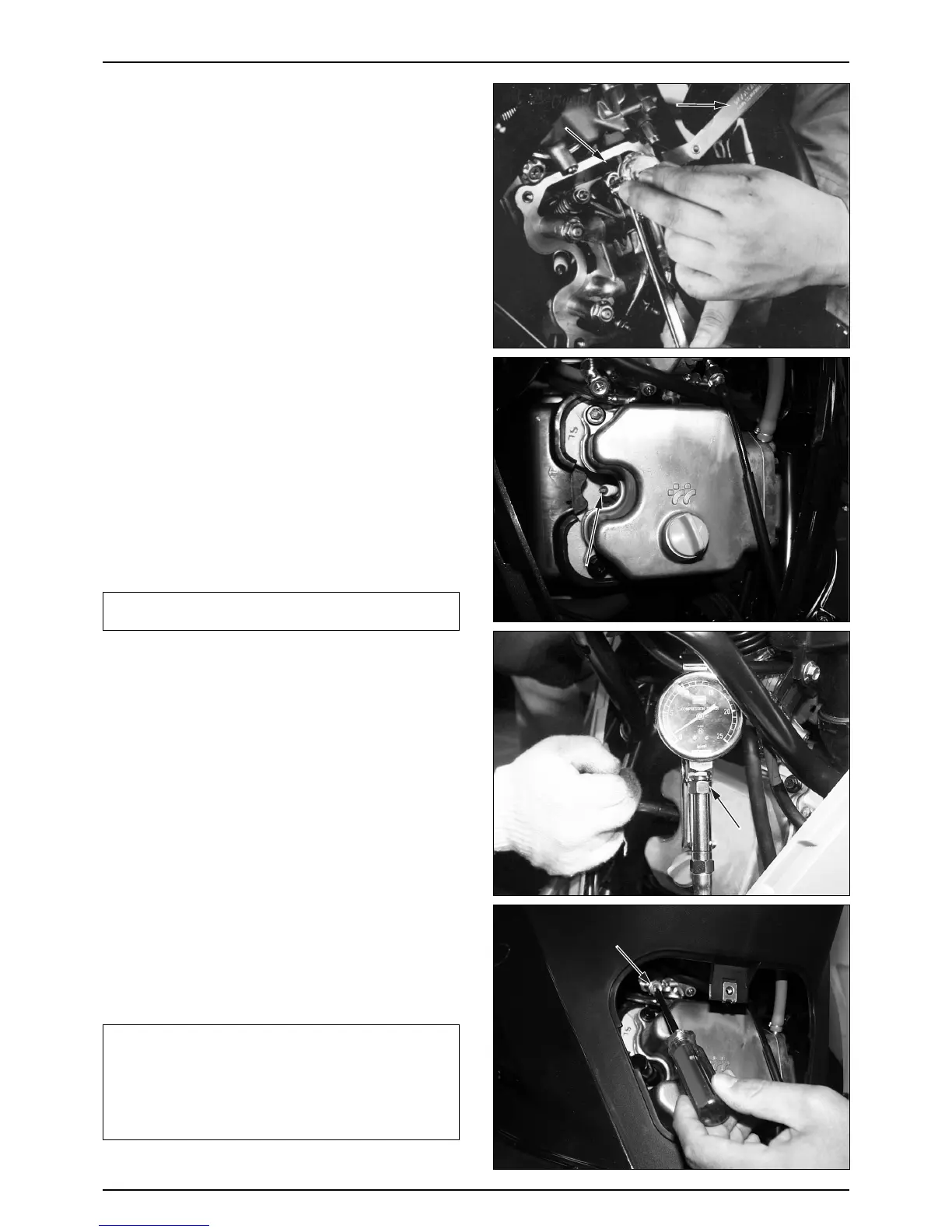

CYLINDER COMPRESSION PRESSURE

● Start and warm up the engine.

● Remove the plug maintenance cover.

● Stop engine, and remove the spark plug cap and spark

plug.

● Install a compression gauge.

● Open the throttle completely, and crank the engine with

the starter motor until the gauge reading rising.

TOOL : COMPRESSION GAUGE

NOTE

•The maximum reading is usually reached within 4~7

seconds.

COMPRESSION PRESSURE : 13.8 kg/cm

2

● If the pressure is low, check the following:

-Inadequate valve clearance adjustment

-Valve leakage

-Leakage from the cylinder head gasket

-Piston/cylinder worn

● If pressure is high, check the following:

-Carbon deposits on the piston head, and cylinder head.

CARBURETOR IDLE SPEED

● Remove the plug maintenance cover. (⇨4-5)

● Check the idle speed and adjust if necessary by turning

the throttle stop screw.

NOTE

•Verify all engine adjustments satisfy specifications.

Make adjustments, if necessary.

•Heat the engine to make accurate idling inspection

and adjustment. Stand the vehicle on the main stand.

•Turn the throttle stop screw and make adjustments to

prescribed idling speed.

3-6

INSPECTIONS / ADJUSTMENTS

Loading...

Loading...