6-16 Using Explicit Messaging

PowerFlex® 755 Drive Embedded EtherNet/IP Adapter User Manual

Publication 750COM-UM001A-EN-P

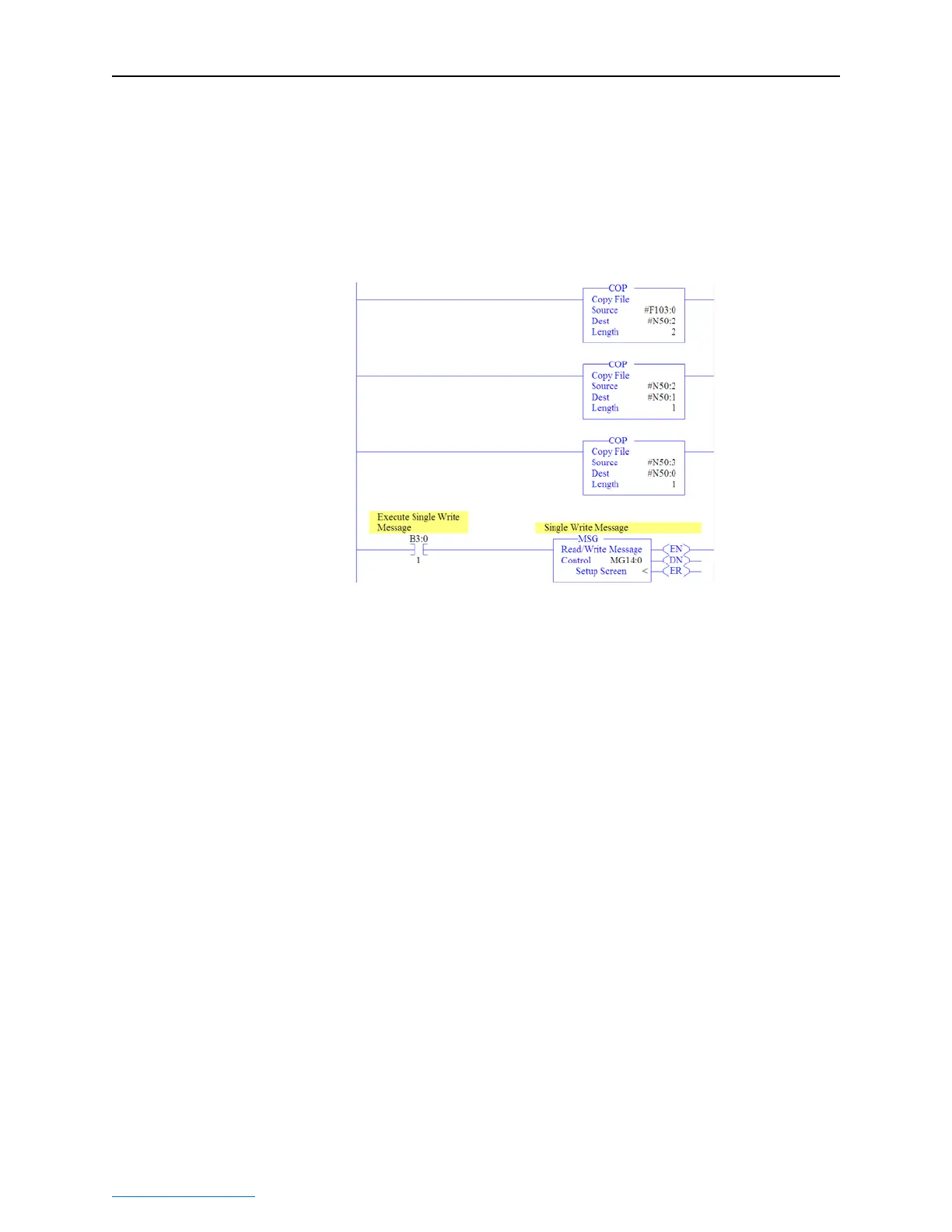

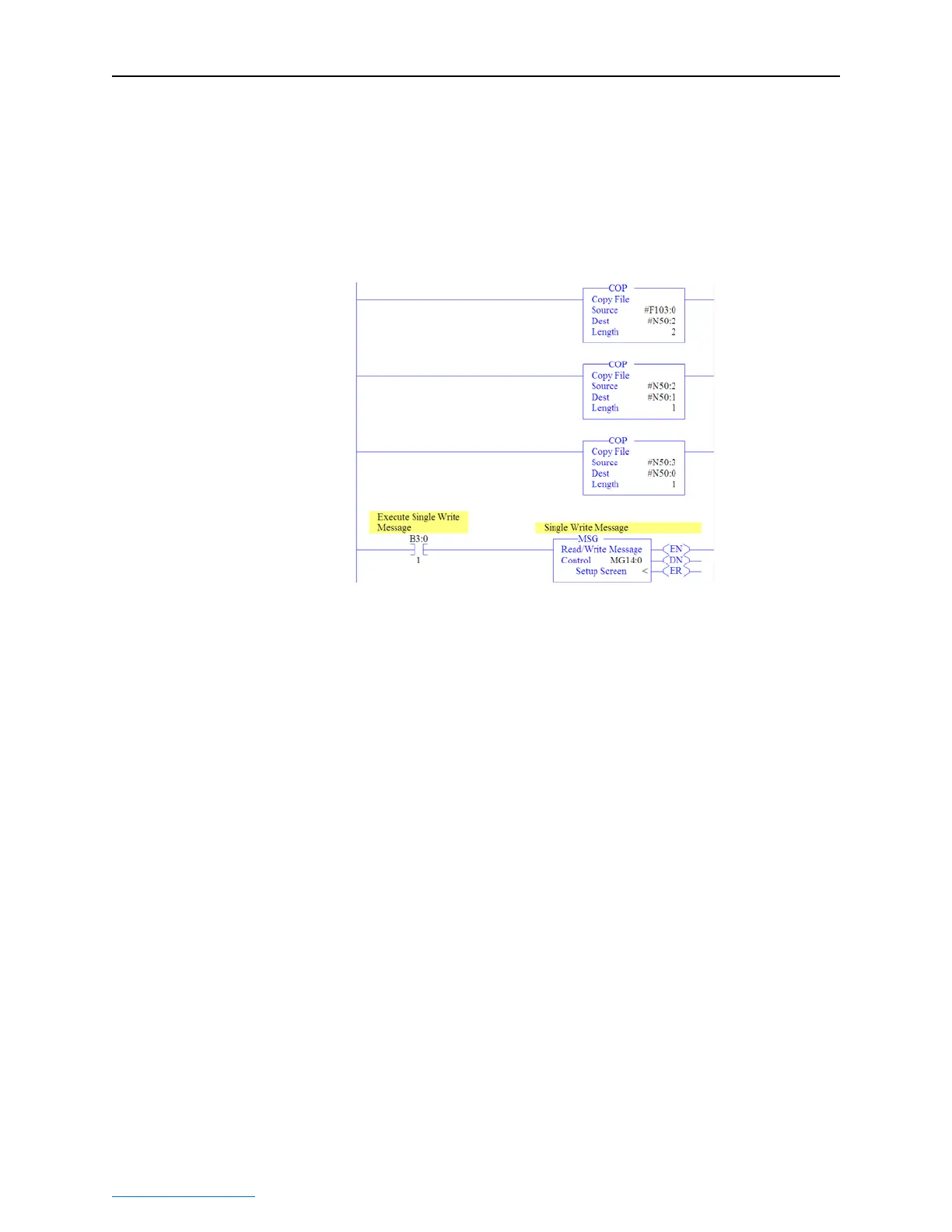

PLC-5 Example Ladder Logic Program to Write Single Parameter

A Generic Set Attribute Single message is used to write to a single

parameter. This write message example writes a value to the 32-bit

REAL (floating point) parameter 535 - [Accel Time 1] in a PowerFlex

750-Series drive.

Figure 6.18 Example Ladder Logic Explicit Messaging Program for Write Single

Three COP (Copy) instructions are required to convert the 16-bit integer

data table addresses N50:0 (Least Significant Word) and N50:1 (Most

Significant Word) to a 32-bit REAL (floating point) data table address

F103:0 for correct presentation. The first COP instruction correctly

writes the 32-bit REAL (floating point) value. The second and third

COP instructions swap the LSW and MSW.

Loading...

Loading...