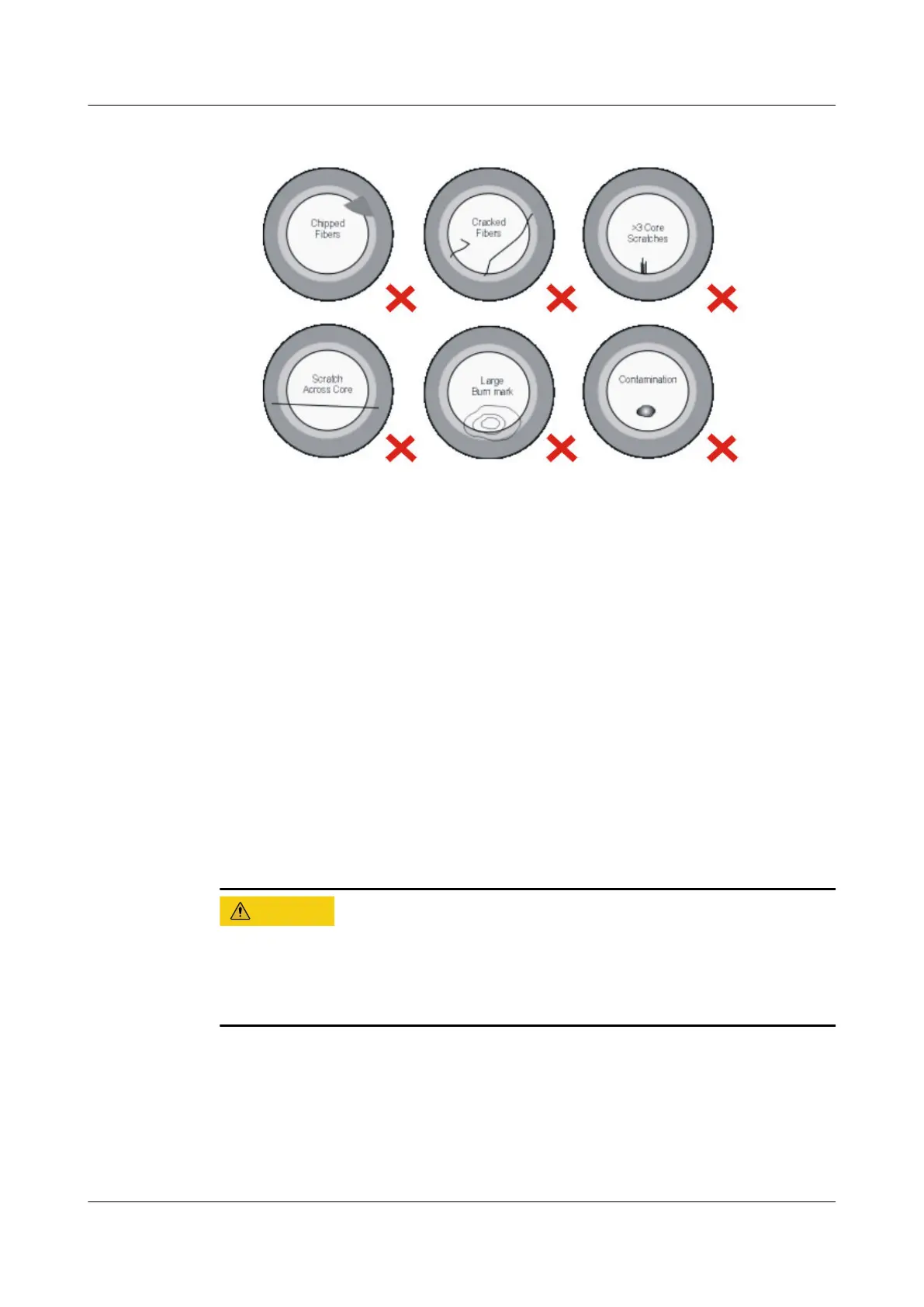

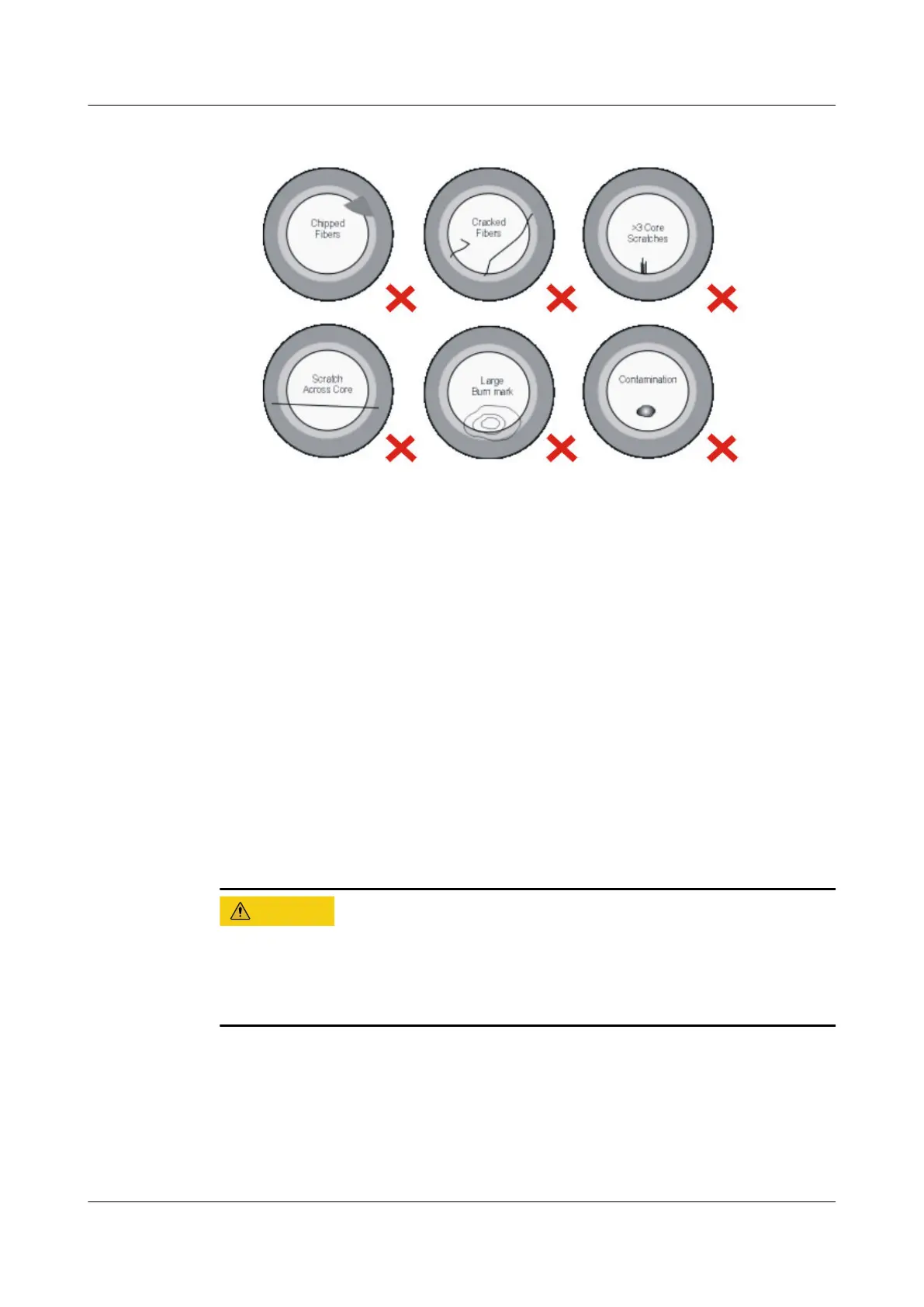

Figure 4-243 Unacceptable bers with imperfections

4. If any dirt is detected, clean the optical ber connector. For details, see

"Cleaning Optical Fiber Connectors Using the Cassette Cleaner" and "Cleaning

Optical Fiber Connectors Using Lens Tissue".

5. If any damage is detected, replace the

ber.

4.2.4.5.5 Inspecting the Optical Fiber Link

This section describes the insertion loss and reection requirements of optical links

and the method of checking the quality of optical links for the application of 50G

optical modules with the PAM4 coding technology.

Tools, Equipment, and Materials

Tools and instruments for checking optical ber links are as follows:

● OTDR meter

● Fiber microscope

Precautions

Because the transmit optical power of the OTDR meter is much higher than the

damaged optical power threshold at the receive end, the optical ber must be

removed from the optical module when the OTDR meter is used to test the optical

path quality.

Currently, the Ethernet port rate is increasing. Since the 50G optical module link

uses the PAM4 encoding technology, there are higher requirements on the optical

ber and cable quality and the link is more sensitive to multipath reection

interference of signals. If the ber link connector, ber section, or ber splicing

surface is dirty, optical signals are reected back and forth on the ber link,

causing interference due to co-channel noise on the receive side. As a result, the

optical link is unstable or intermittently disconnected.

HUAWEI NetEngine 8000 F

Hardware Guide 4 Hardware Installation and Parts Replacement

Issue 05 (2023-03-31) Copyright © Huawei Technologies Co., Ltd. 592

Loading...

Loading...