16 ENGINE 131

300159-10

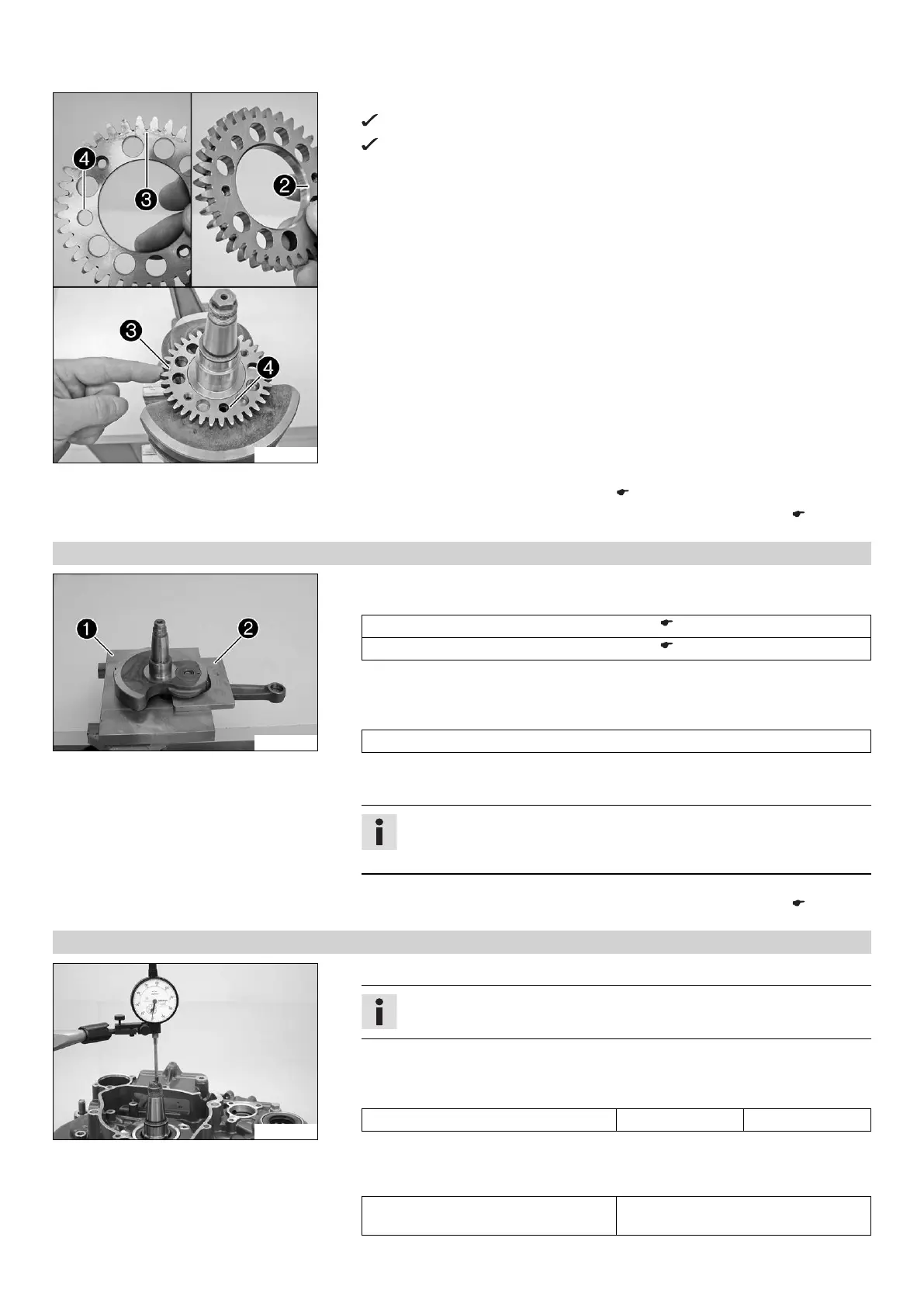

– Place the drive wheel on the crankshaft.

The dowel of the crankshaft must fit in the drill hole

.

The side of the drive wheel with the punch mark

must be visible after

assembly, and the side with the bevel

must be in contact with the

crankweb.

Finishing work

– Install the crankshaft bearing inner ring. ( p. 131)

– Measure the axial clearance of the crankshaft and the balancer shaft. ( p. 131)

16.4.9 Installing crankshaft bearing inner ring

302150-10

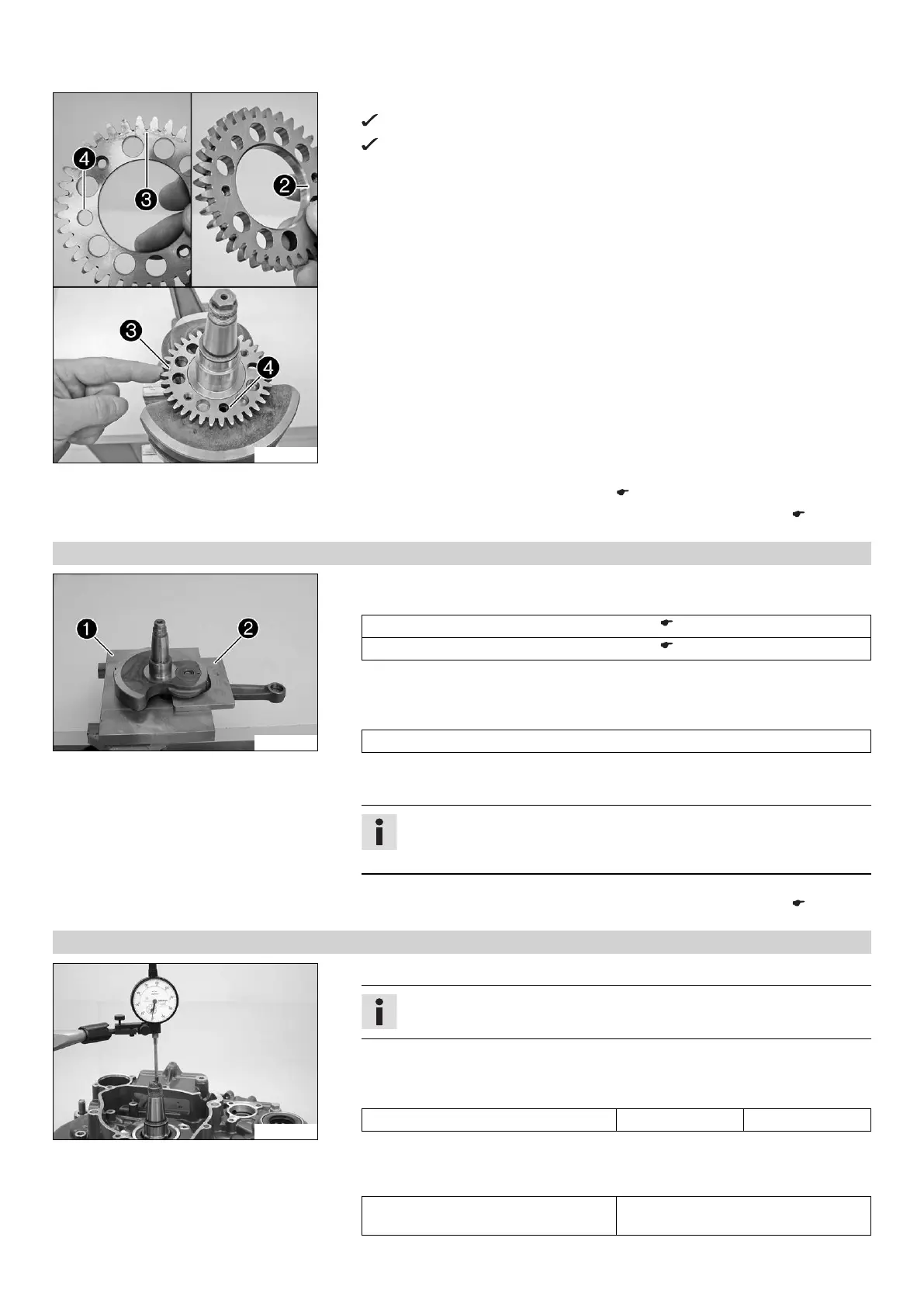

Main work

–

Fix the crankshaft with special tools

and

in the vise.

Upper part, pressing-out tool (75029047050) ( p. 234)

Under part, pressing-out tool (75029047051) ( p. 235)

– Push on the compensation shim.

– Heat the special tool. Install the inner bearing race.

Guideline

120 °C (248 °F)

– Repeat the operation on the opposite side.

– Make sure that the new inner bearing race is installed flush.

Info

After changing the crankshaft bearing and the conrod bearing, measure the

axial play of the crankshaft.

Finishing work

– Measure the axial clearance of the crankshaft and the balancer shaft. ( p. 131)

16.4.10 Measuring axial clearance of crankshaft and balancer shaft

300126-10

– Insert the crankshaft and balancer shaft in the right engine casing.

Info

Do not forget the dowels.

– Mount the left engine casing.

– Mount and tighten the screws.

Guideline

Screw, engine case M6 10 Nm (7.4 lbf ft)

– Mount the dial gauge support on the engine case and measure and note the axial

clearance of the crankshaft.

Guideline

Crankshaft - axial clearance 0.15… 0.25 mm (0.0059…

0.0098 in)

Loading...

Loading...