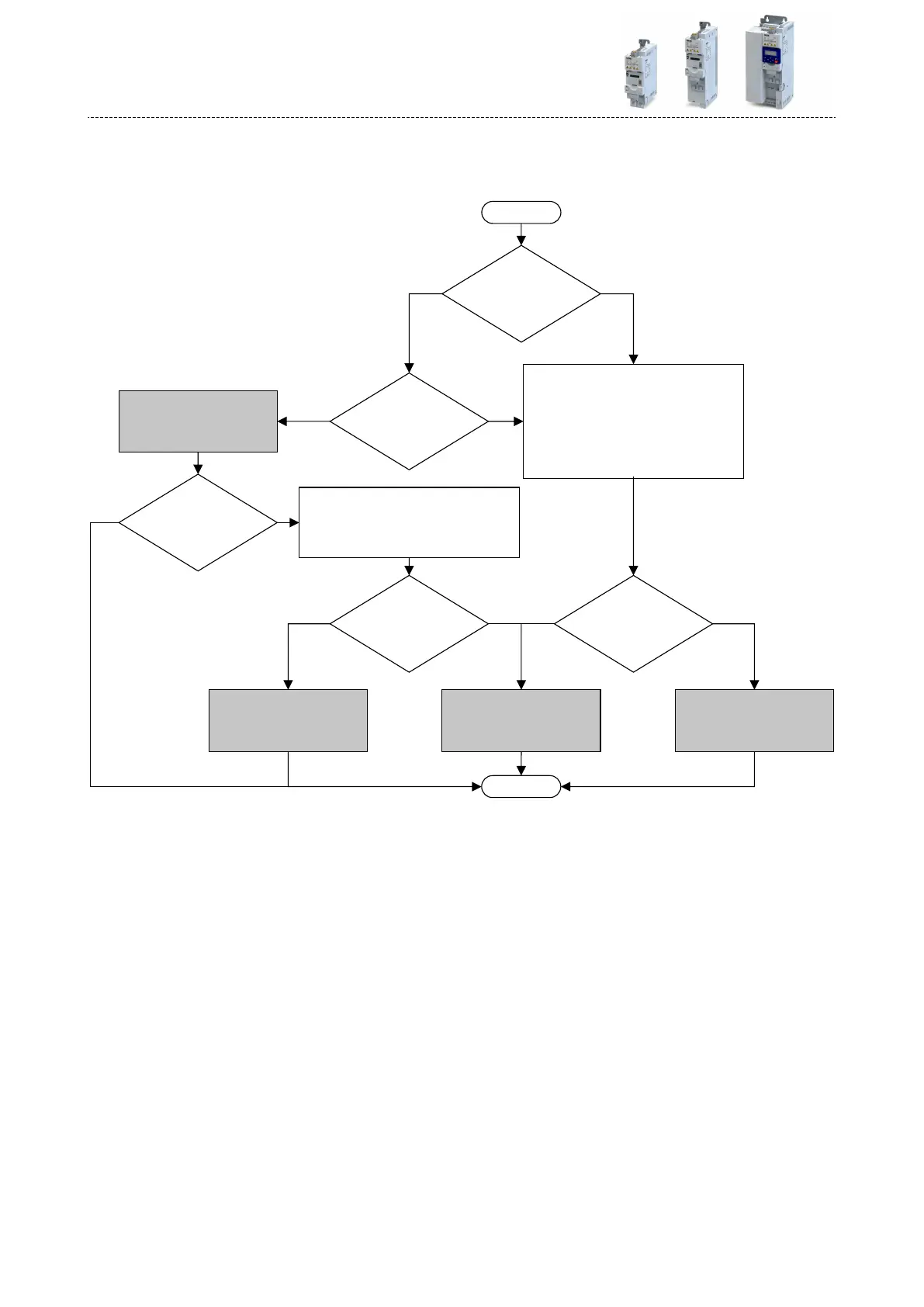

Performing opmisaon with engineering tool

The following ow diagram shows the opmisaon process with an engineering tool

(e. g. »EASY Starter«):

Yes

No Yes

Yes NoNo

No

NoYes

End

d)

Automatic motor calibration

(non-energized)

b)

Tuning of the motor

and the speed controller

c)

Automatic motor identification

(energized)

Set manually:

• Mechanical load and its coupling

to the motor

• Filter time for speed feedback

Set manually:

• Motor data (e.g. according to data

on the motor nameplate)

• Motor control type

• Mechanical load and its coupling

to the motor

• Filter time for speed feedback

Lenze motor

connected?

Identification

(energized)

possible?

Identification

(energized)

possible?

Engineering tool

available?

Adaptation of the

speed controller

required?

a)

Select motor from motor

catalogue

Start

Yes

a) No maer which opon suits you best, rst the relevant motor data must be set. By selecng the motor from the motor catalogue, you

benet from very accurate Motor equivalent circuit diagram data.

4Motor selecon from motor catalogue ^ 197

b) If you already have an opmised system, but the load adjustment has changed, it makes sense to just re-inialise the speed controller.

4Tuning of the motor and the speed controller ^ 198

c) If the applicaon enables you to energise the system during the opmisaon procedure, carry out an automac idencaon. This proce-

dure results in the best possible parameter sengs.

4Automac motor idencaon (energized) ^ 199

d) If the applicaon does not enable you to energise the system during the opmisaon procedure, carry out an automac calibraon.

4Automac motor calibraon (non-energized) ^ 200

Motor control

Opmisaon of the control loops

194

Loading...

Loading...