Example for operang mode

In the following example, the "Deacvate PID controller" funcon is used to deacvate the

PID control temporarily:

•

As standard setpoint source, the frequency preset 1 is set to 20 Hz.

•

Switch S1 starts the motor in forward direcon of rotaon. Switch S1 in the inial posion

stops the motor again.

•

Switch S2 deacvates the PID control. The motor is then driven in a speed-controlled way.

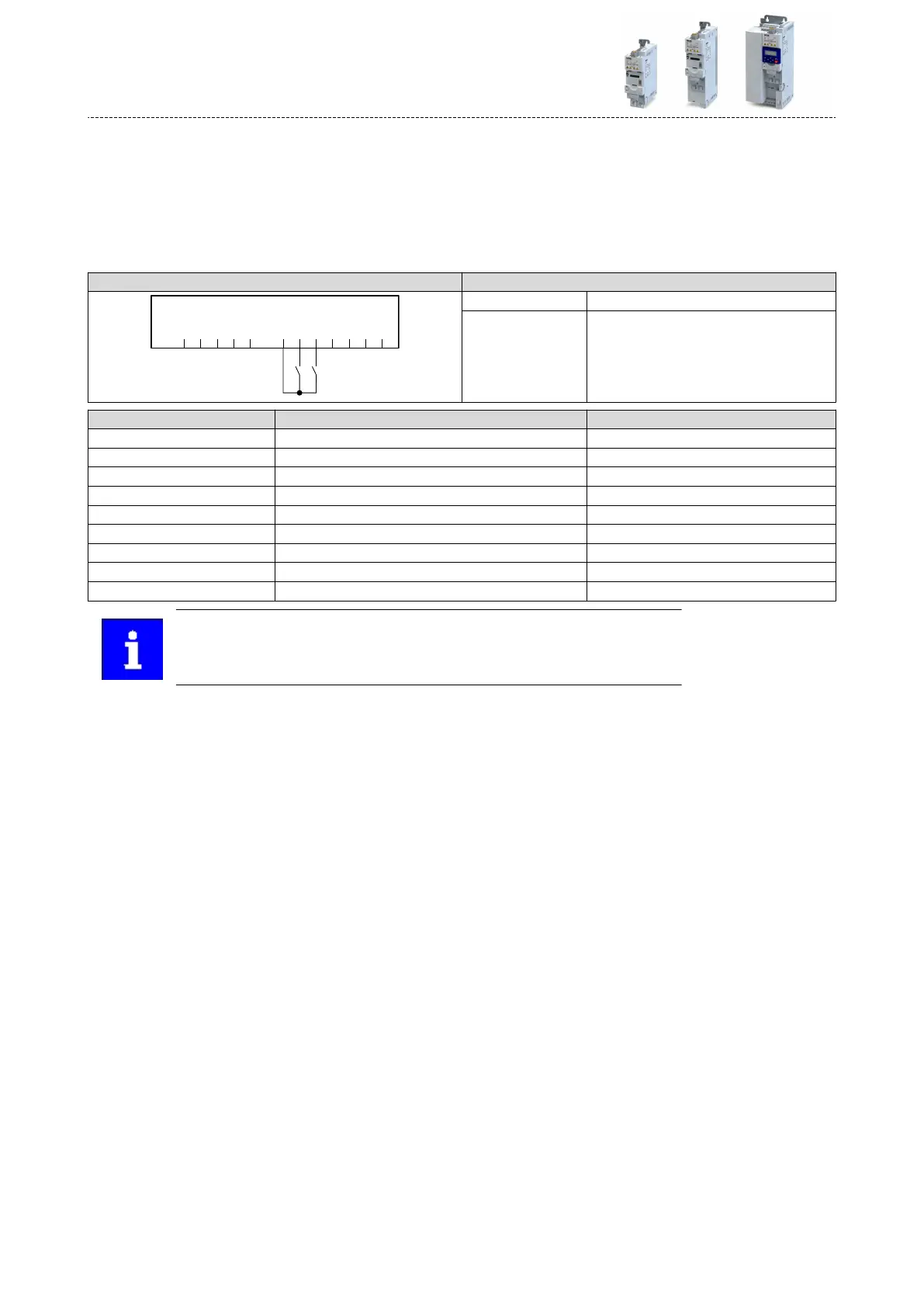

Connecon plan funcon

GND

AI1

AI2

AO1

10V

24V

DI1

DI2

DI3

DI4

DI5

DO1

X3

S1 S2

Switch S1 Run

Switch S2 Deacvate PID controller

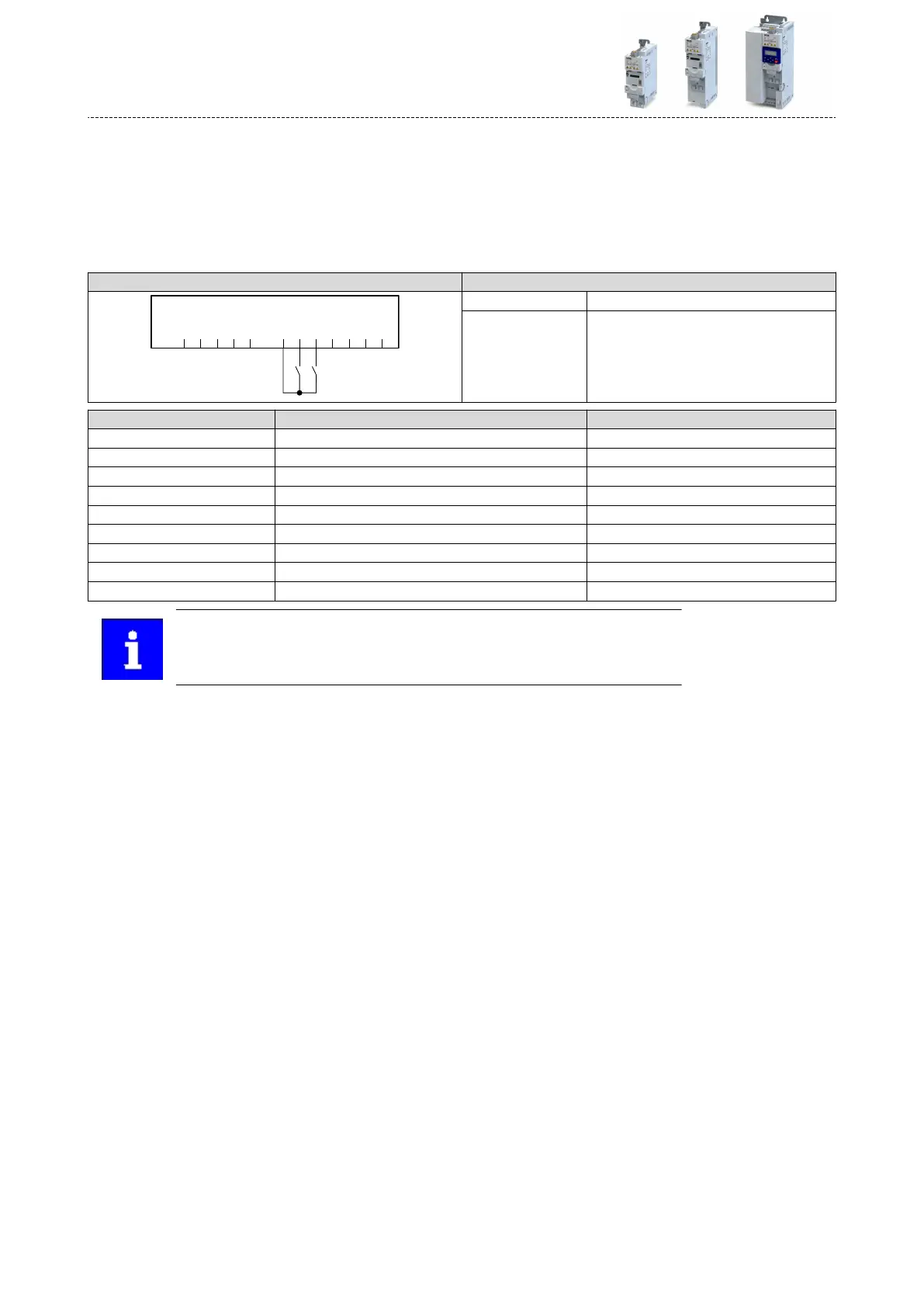

Parameter Name Seng for this example

0x2631:001 (P400.01) Enable inverter Constant TRUE [1]

0x2631:002 (P400.02) Run Digital input 1 [11]

0x2631:004 (P400.04) Reset fault Not connected [0]

0x2631:045 (P400.45) Deacvate PID controller Digital input 2 [12]

0x2824 (P200.00) Control selecon Flexible I/O conguraon [0]

0x2838:003 (P203.03) Stop method Standard ramp [1]

0x2860:001 (P201.01) Frequency control: Default setpoint source Frequency preset 1 [11]

0x2911:001 (P450.01) Frequency setpoint presets: Preset 1 20 Hz

0x2916 (P211.00) Maximum frequency 50 Hz

The example assumes that the process controller has been congured accord-

ingly. 4Conguring the process controller ^ 407

Flexible I/O conguraon

Process controller funcon selecon

586

Loading...

Loading...