- Check the diaphragm has not hardened and is

not broken.

- Replace with a new one if necessary.

- Re-fit the needle to the vacuum valve.

- Ensure the spring is correctly positioned, both on

the needle and in its seat.

- Push and turn the bayonet fitting 1/8th of a turn,

back into position.

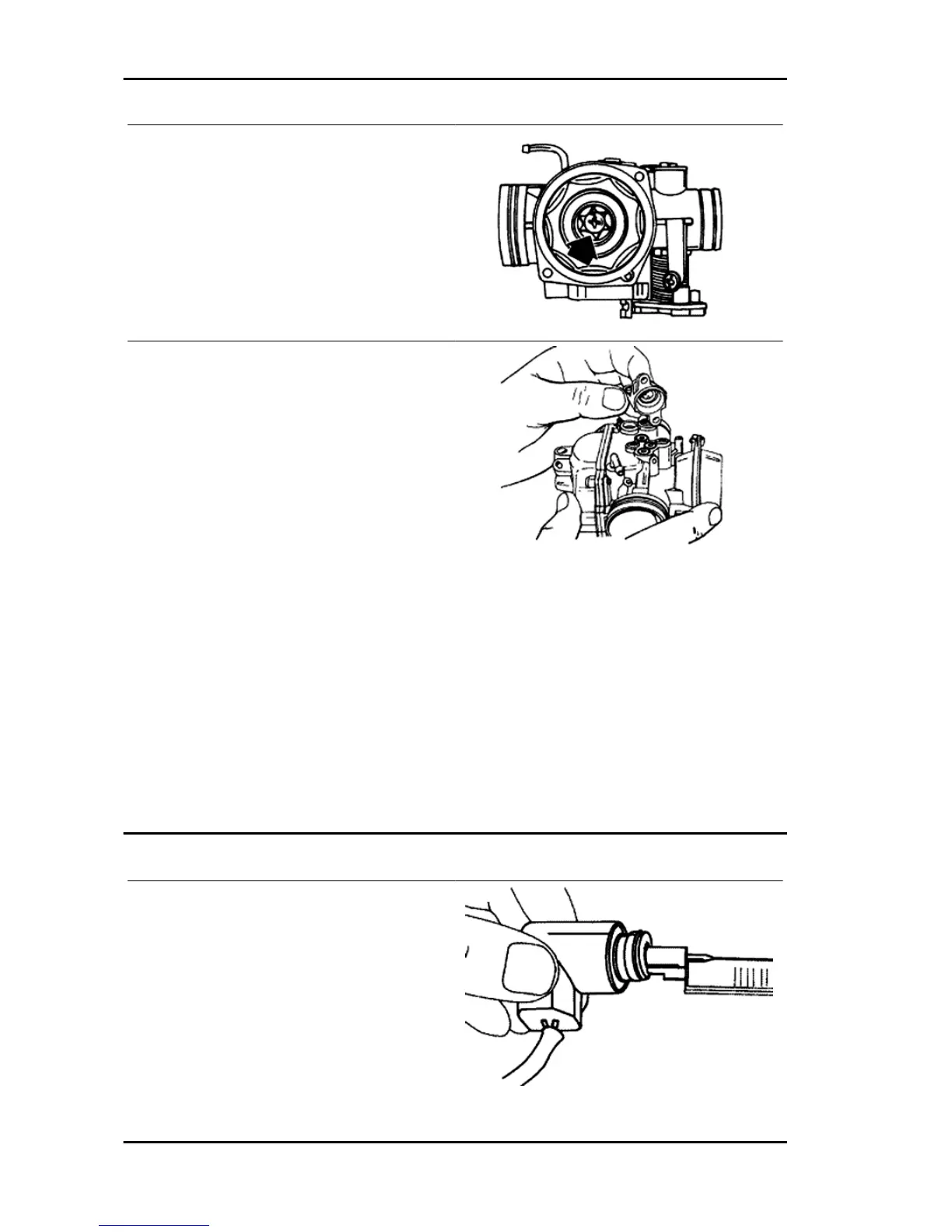

- Re-fit the vacuum petrol valve on the carburettor

body, ensuring that the needle is inserted in the

atomiser.

- Gradually screw in the vacuum valve to the point

where the lobe on the diaphragm locates in its

notch; with the valve in such a position, the main

vacuum opening should be in line with the axis of

the bore of the carburettor, offset towards the but-

terfly valve side.

- Re-fit the spring on the valve.

- Re-fit the vacuum chamber cover, aligning the

reference mark on the cover with the one on the

diaphragm.

- Tighten the screw fasteners to the specified tight-

ening torque.

- Take off the auto-choke seat and blow it out.

- Replace the gasket with a new one and tighten

the two screw fasteners.

Inspecting the automatic choke device

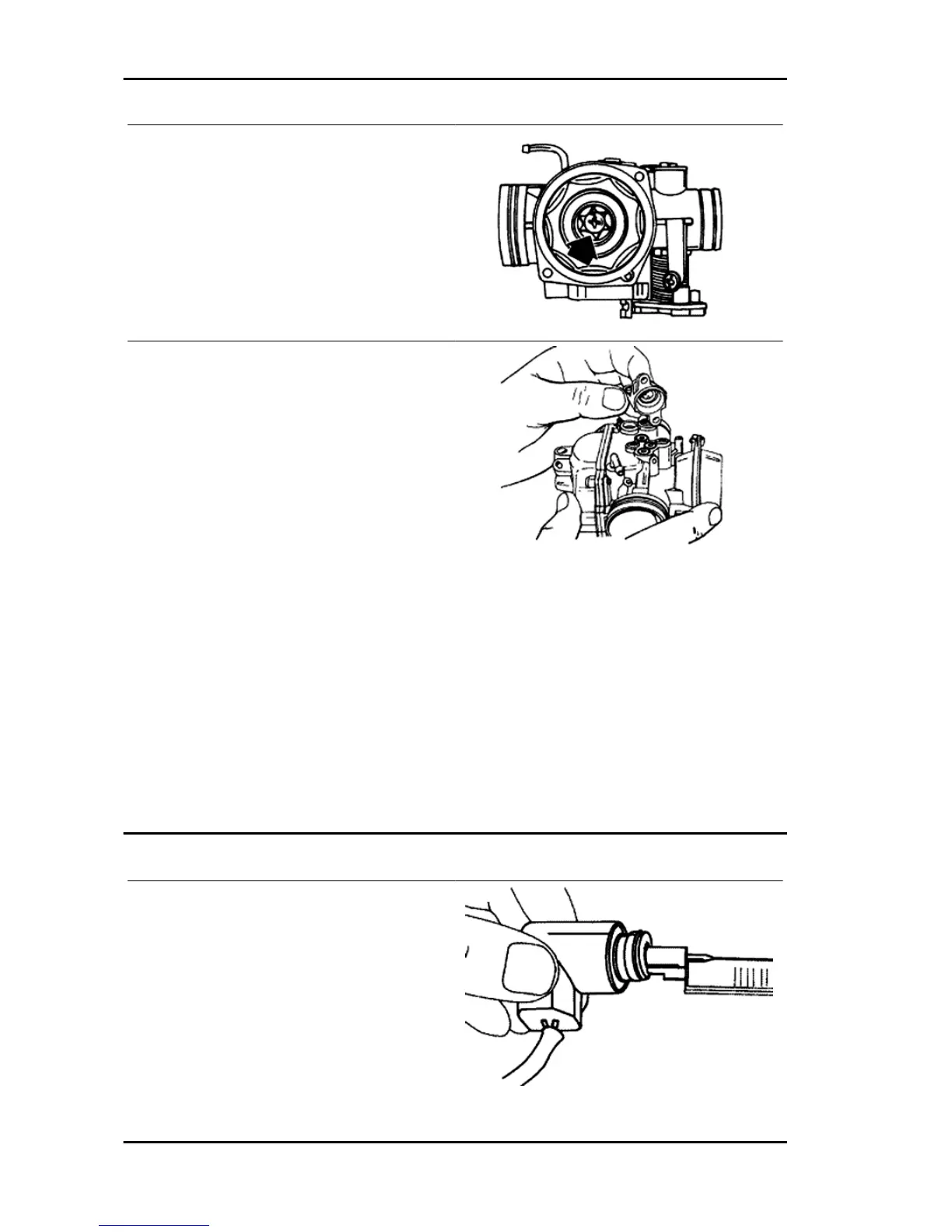

- Inspect the auto-choke piston for signs of scoring

and oxidation.

- Check the auto-choke piston does not stick, but

is free to move back and forth in its housing.

- Check the gasket is not deformed.

- The auto-choke piston should be more or less

fully retracted at room temperature.

- Measure the distance by which the auto-choke

piston projects.

Engine Liberty 125 - 200 4tempi

ENG - 134

Loading...

Loading...