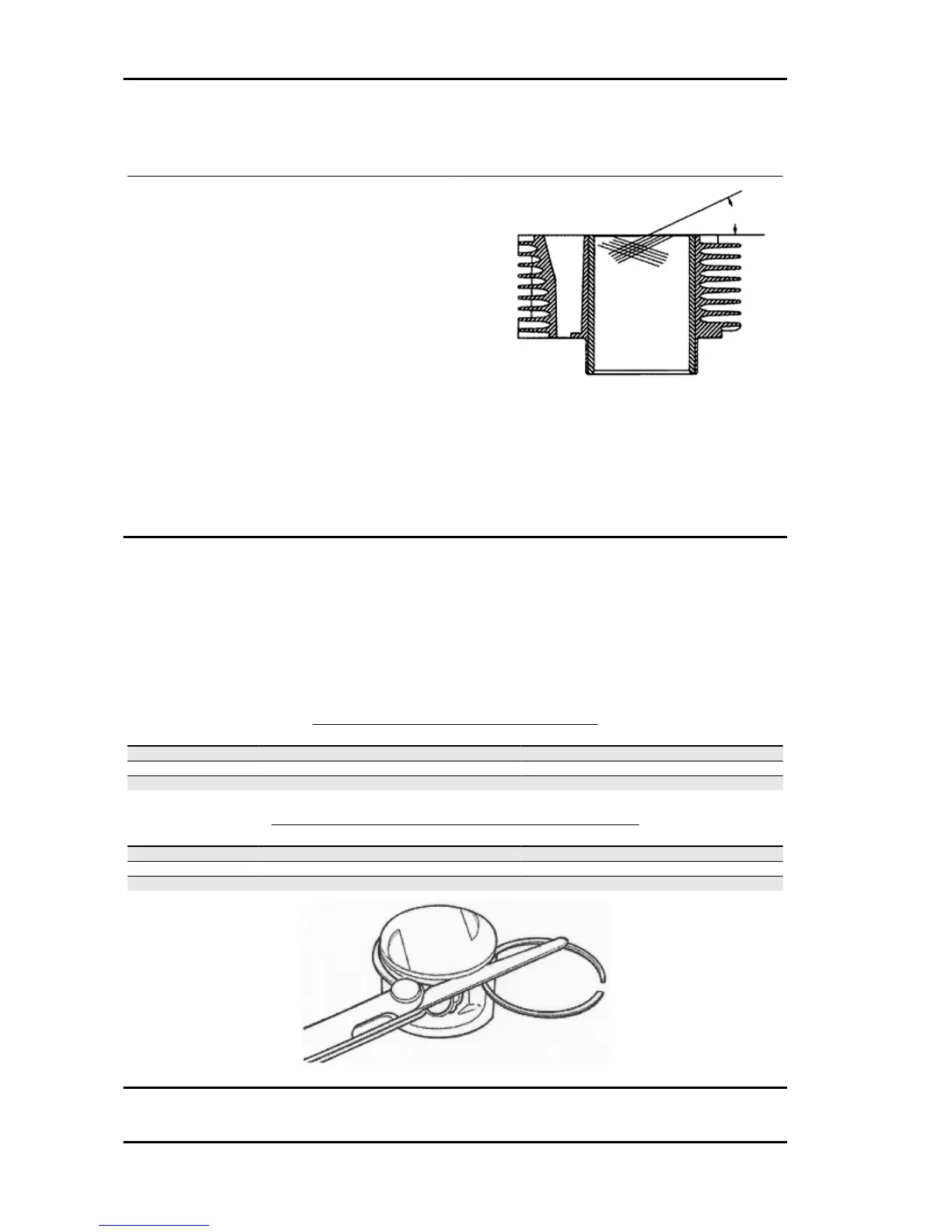

Maximum allowable run-out:

0.05 mm

- The cylinder rectifying operation should be car-

ried out with a surfacing that respects the original

angle.

- The cylinder surface roughness should be 0.9

micron.

- This is indispensable for a good seating of the

sealing rings, which in turn minimises oil consump-

tion and guarantees optimum performance.

- The pistons are oversized due to cylinder rectifi-

cation and are subdivided into three categories

1st, 2nd, 3rd with 0.2-0.4-0.6 mm oversize. They

are also classified into 4 categories A-A, B-B, C-

C, D-D.

Inspecting the piston

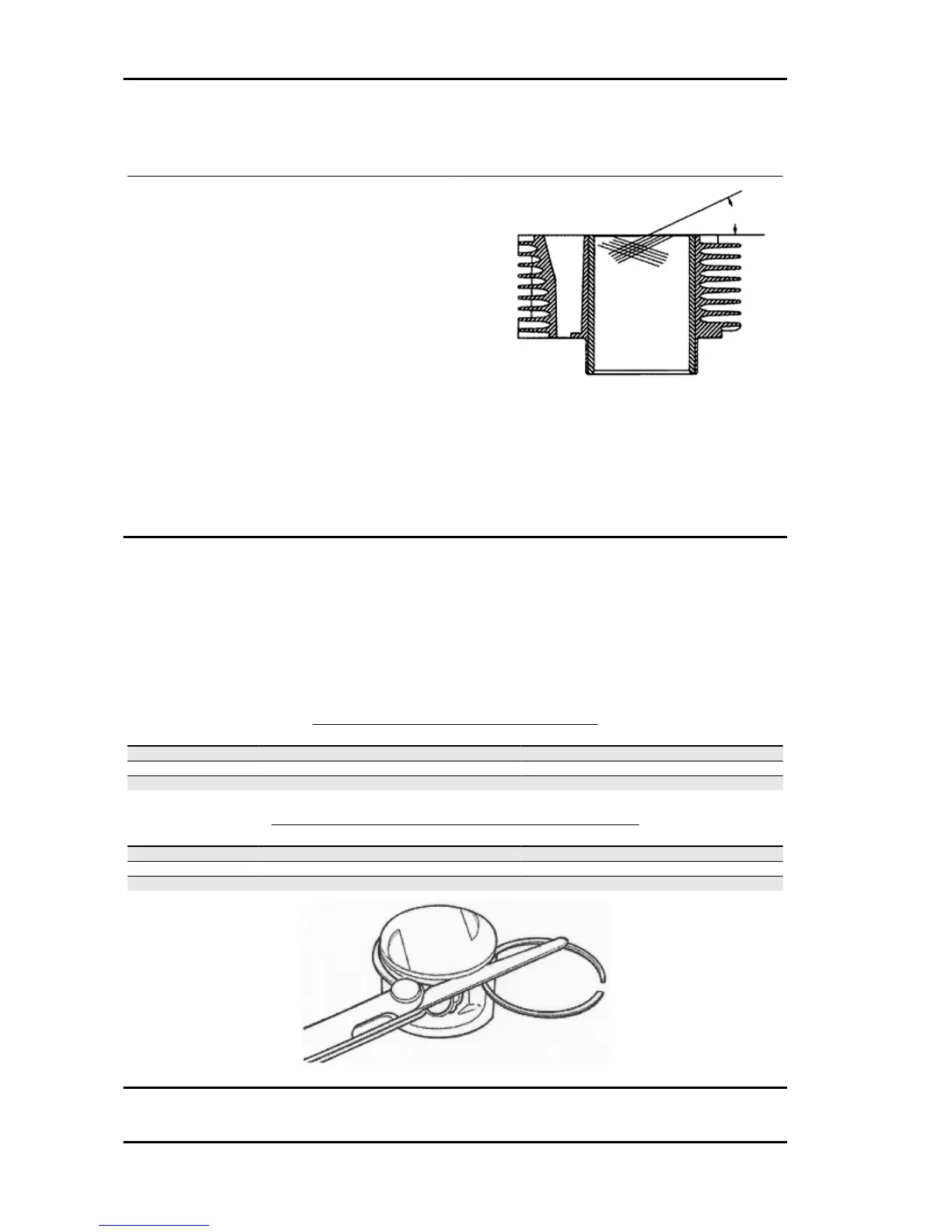

- Carefully clean the seal housings.

- Measure the coupling clearance between the seal rings and the grooves using suitable sensors, as

shown in the diagram.

- If the clearance is greater than that indicated in the table, replace the piston.

STANDARD COUPLING CLEARANCE

Name

Description Dimensions Initials Quantity

Top piston ring 0.025 ÷ 0.070

Middle piston ring 0.015 ÷ 0.060

oil scraper 0.015 ÷ 0.060

MAXIMUM ADMITTED CLEARANCE AFTER USE

Name

Description Dimensions Initials Quantity

Top piston ring 0.080 mm

Middle piston ring 0.070 mm

oil scraper 0.070 mm

Engine Liberty 125 - 200 4tempi

ENG - 94

Loading...

Loading...