Detailed Description

2.3 Setpoint/actual-value system

Velocities, Setpoint/Actual-Value Systems, Closed-Loop Control (G2)

Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

2-23

2.3 2.3 Setpoint/actual-value system

2.3.1 General

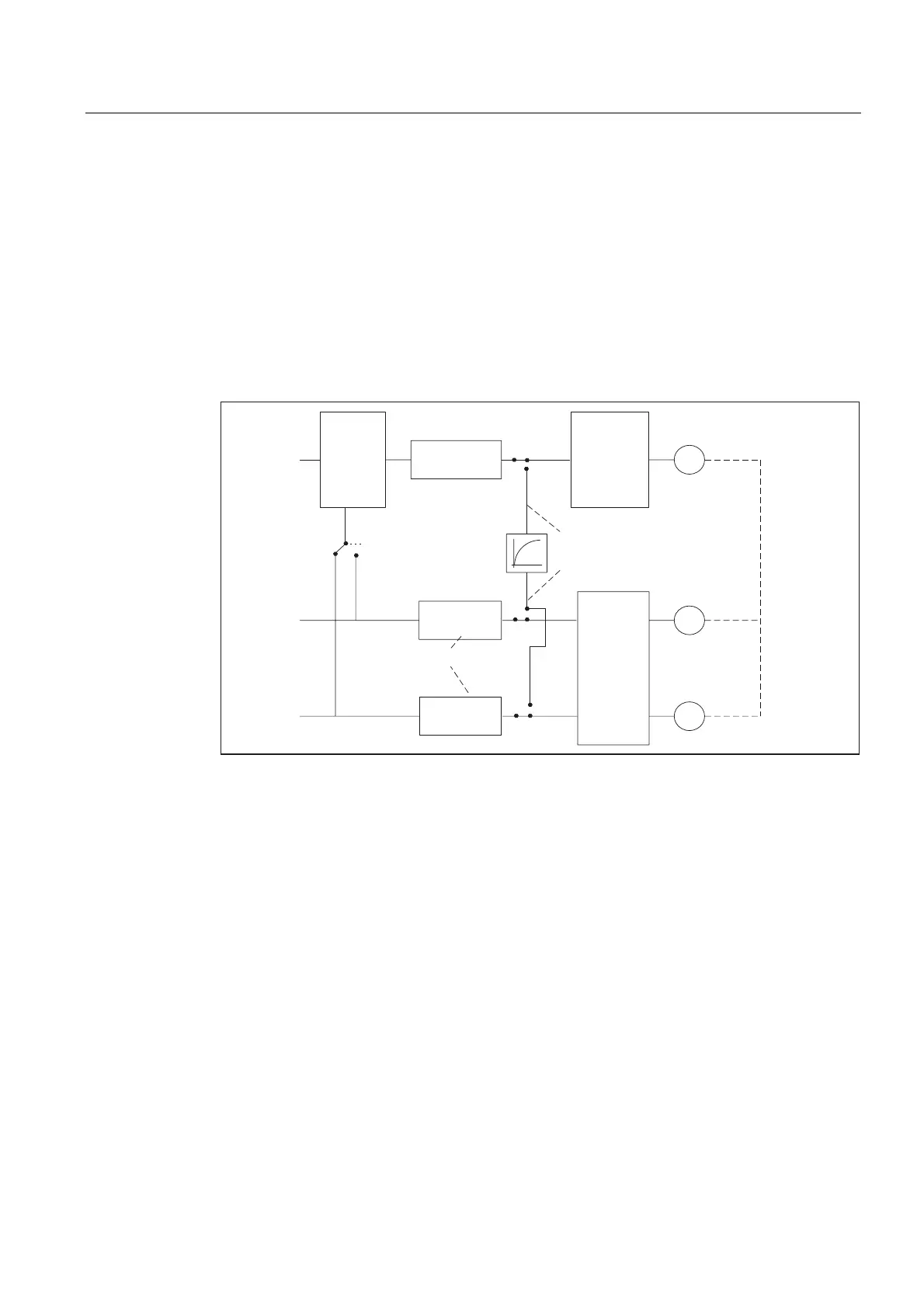

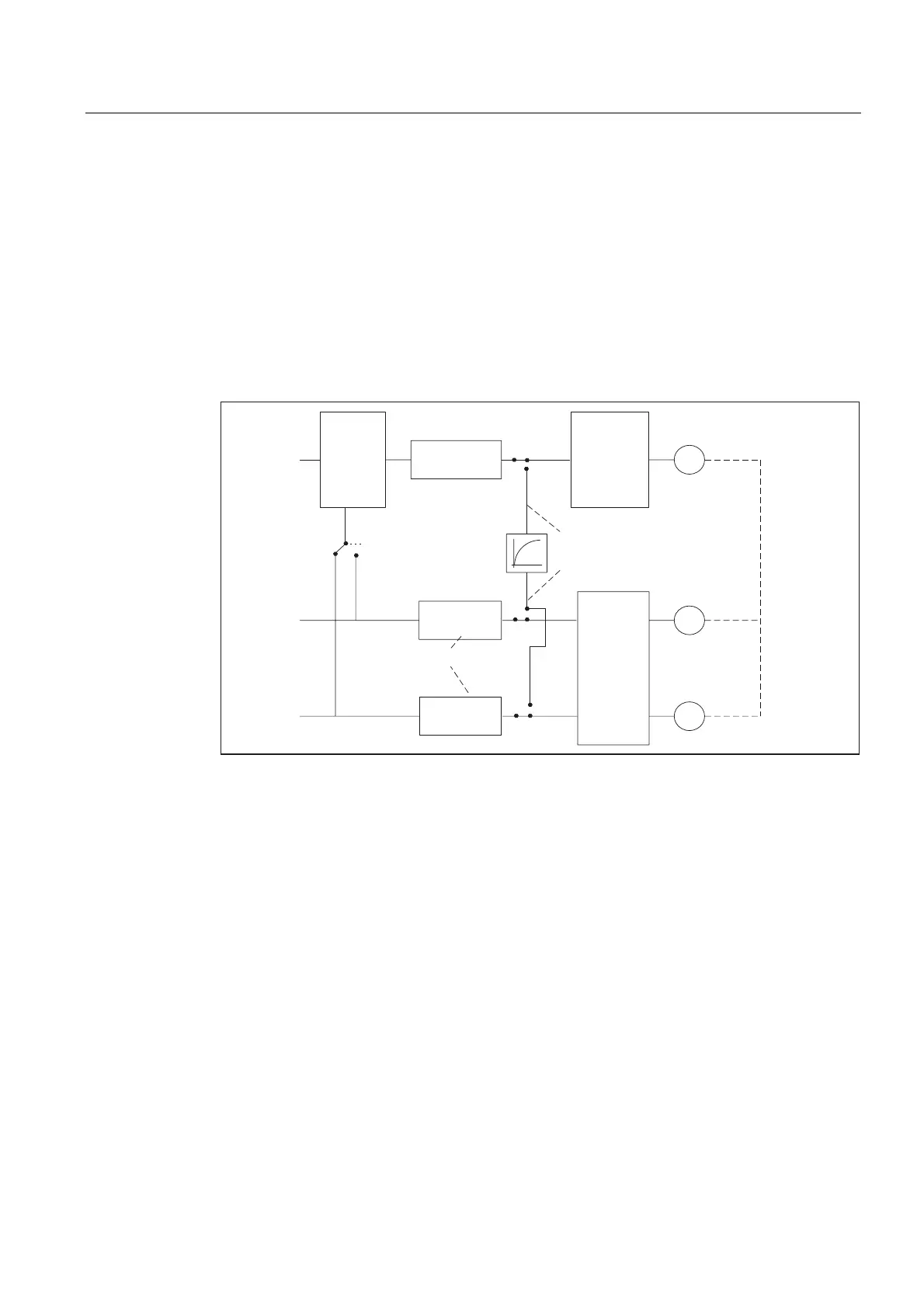

Control loop

A control loop with the following structure can be configured for every closed-loop controlled

axis/spindle:

&75/287B7<3( 6,08/$7,21

(1&B7<3( 6,08/$7,21

180B(1&6

0

*

*

&ORVHG

ORRS

FRQWURO

6SHHGVHWSRLQW

RXWSXW

6SHHG

VHWSRLQW

URXWLQJ

$FWXDOYDOXH

SURFHVVLQJ

$FWXDO

YDOXH

URXWLQJ

,)&SRVLWLRQ

PHDVXULQJ

V\VWHP

$FWXDOYDOXH

SURFHVVLQJ

0RWRU

(QFRGHU

(QFRGHU

Fig. 2-1 Block diagram of a control loop

Setpoint output

A setpoint can be output for each axis/spindle. Setpoints are output digitally to the actuator

on SINUMERIK 840D/810D.

Actual-value acquisition

A maximum of two measuring systems can be connected for each axis/spindle, e.g. a direct

measuring system for machining processes with high accuracy requirements and an indirect

measuring system for highspeed positioning tasks.

Enter the number of encoders used in machine data:

MD30200 $MA_NUM_ENCS (number of encoders).

In the case of two actual-value branches, the actual value is acquired for both branches.

The active measuring system is always used for position control, absolute value calculation

and display. If both measuring systems are activated at the same time by the PLC interface,

positioning measuring system 1 is chosen internally by the control.

Loading...

Loading...