Detailed Description

2.4 Frames

Axis Types, Coordinate Systems, Frames (K2)

Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

2-39

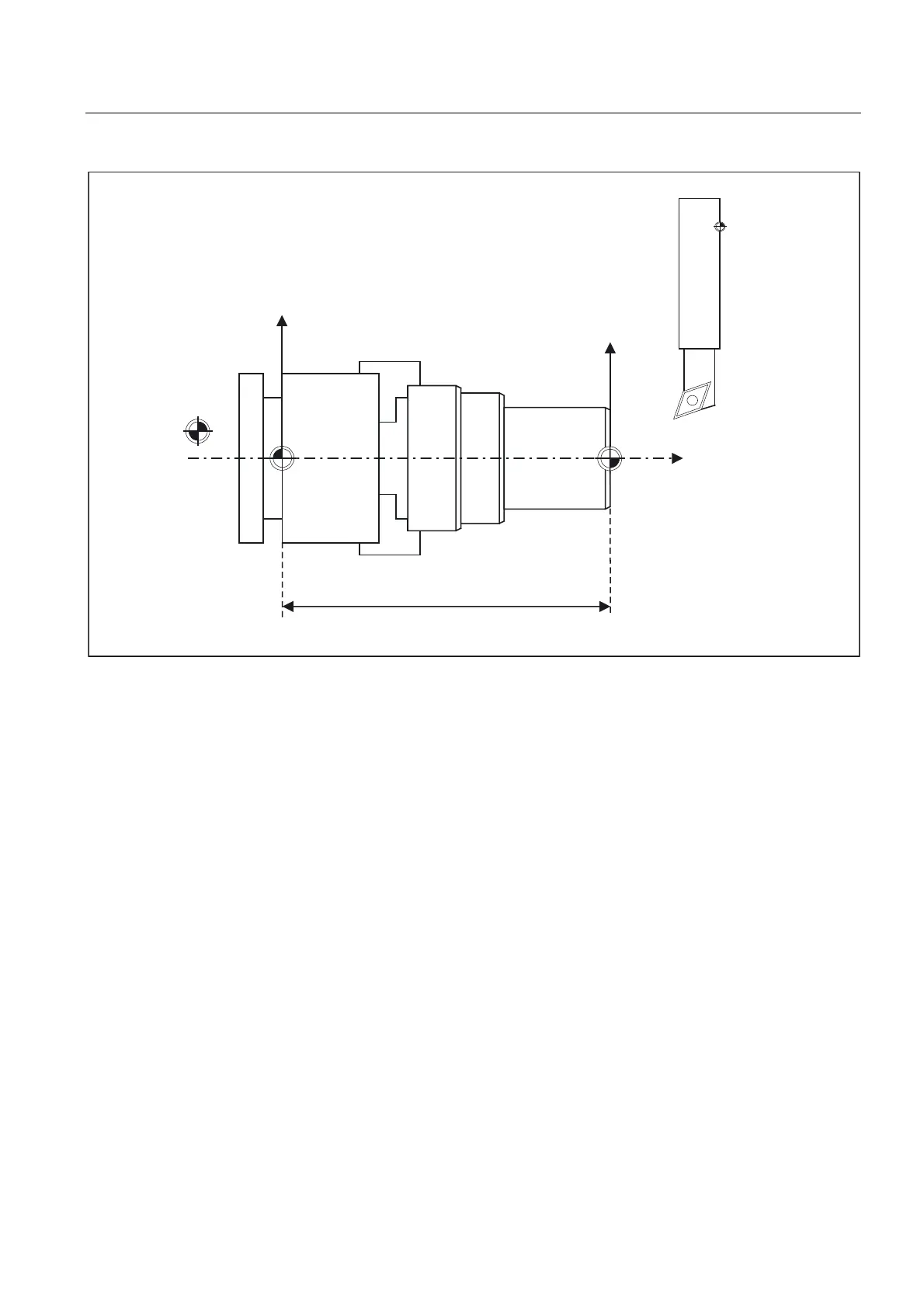

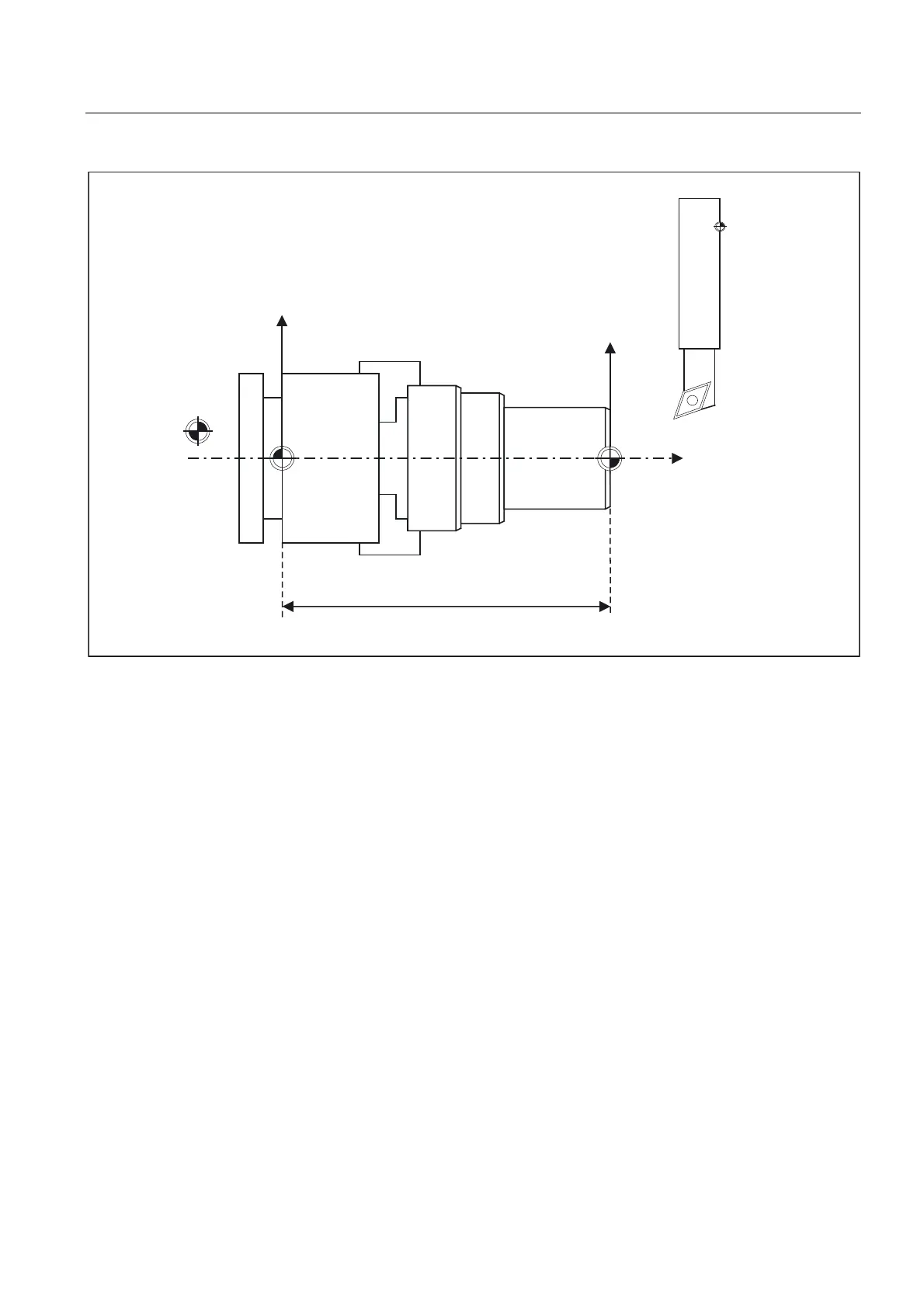

[

3B$&7)5$0(

]

:&6

0&6

5HIHUHQFHSRLQW

7RROUHIHUHQFH

SRLQW

The position of the reference point R is defined by cam switches. The reference point must

be approached each time the control is activated. The control can only then work with the

measuring system and transfer all position values to the coordinate systems.

The machine zero M defines the machine coordinate system MCS. All other reference points

refer to the machine zero.

The workpiece zero W defines the workpiece coordinate system in relation to the machine

zero. The programmed part-program blocks are executed in the workpiece coordinate

system.

The toolholder reference point is located on the toolholder locator. By entering the tool

lengths, the control calculates the distance between the tool tip (TCP Tool Center Pos) and

the toolholder reference point.

2.4.2 Frames

A frame is a structure, which contains a value for the translation, fine offset, rotation (only for

geometry axes), scaling and mirroring for each axis. Activating a frame causes a static

coordinate transformation to be carried out via a defined calculation rule.

Loading...

Loading...