5-5 FUEL SYSTEM

B

A small amount of fuel may be released when the fuel

feed hose is disconnected.

Place container under the fuel feed hose or 3-way pipe

with a shop cloth so that released fuel is caught in con-

tainer or absorbed in cloth. Place fuel soaked cloth in

an approved container.

3. Squeeze fuel primer bulb until you feel resistance.

Turn ignition switch “ON” for 3 seconds (to operate fuel

pump), then turn it “OFF”.

Repeat this (“ON” and “OFF”) procedure 3 or 4 times to pres-

surize the fuel system and then check fuel pressure.

4. Measure fuel pressure in line at cranking or idle speed op-

eration.

Fuel pressure : Approx. 235 kPa

(2.4 kg/cm

2

, 34.1 psi.)

5. Stop engine and wait 5 minutes.

z

OFF

ON

FUEL PRESSURE INSPECTION

1. Relieve fuel pressure in fuel feed line. (See page 5-2)

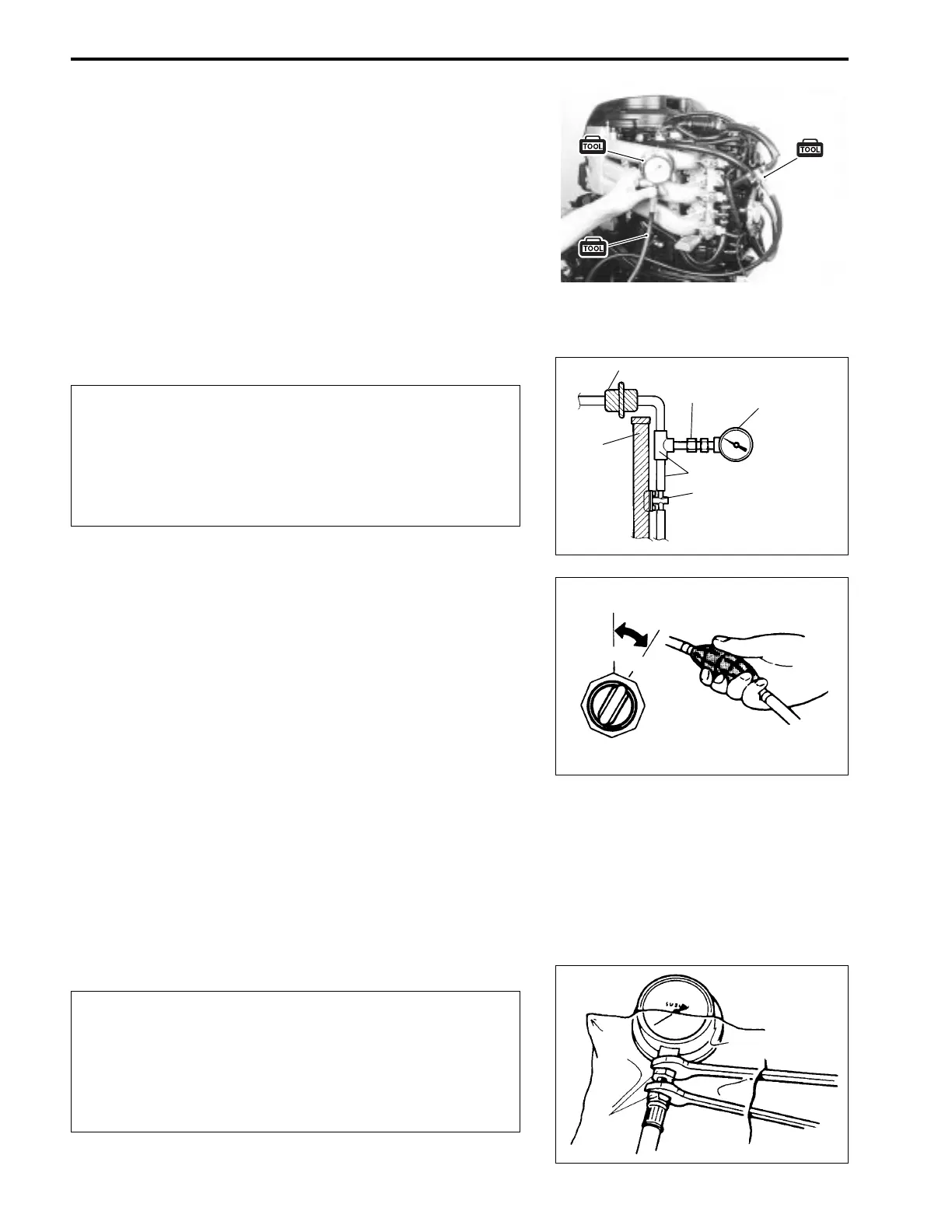

2. Connect special tools (pressure gauge, pressure hose &

pressure joint) between fuel feed hose and 3-way joint pipe

as shown in figure.

Clamp hose securely to ensure no leaks occur during check-

ing.

09912-58441 : Pressure gauge –

aa

aa

a

09912-58431 : Fuel pressure hose –

bb

bb

b

09912-58490 : Fuel pressure joint –

cc

cc

c

1. High pressure fuel filter

2. Fuel delivery gallery

3. 3-way pipe

1

2

3

c

a

b

B

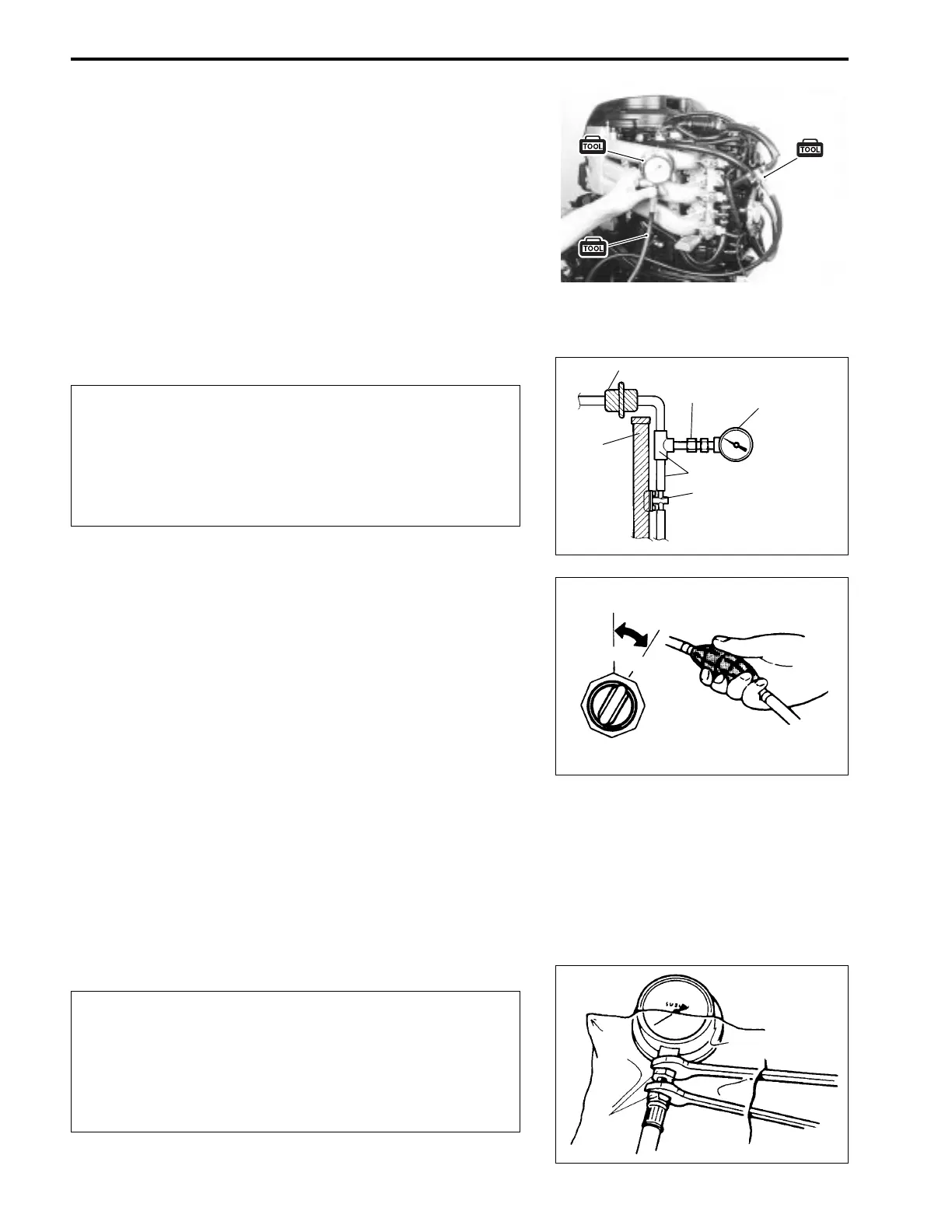

As fuel feed line is still under high fuel pressure, make

sure to release fuel pressure according to following

procedures.

• Place container under joint to catch fuel.

• Cover joint with rag and loosen joint nut slowly to

gradually release fuel pressure.

1

1 Joint nut

Loading...

Loading...