3-11 ENGINE CONTROL SYSTEM

IGNITION CONTROL SYSTEM

OUTLINE

Sensors at specific points on the engine monitor current engine conditions and send signals to the ECM.

Based on these signals, the ECM determines the optimum ignition timing and releases voltage to the igni-

tion coils.

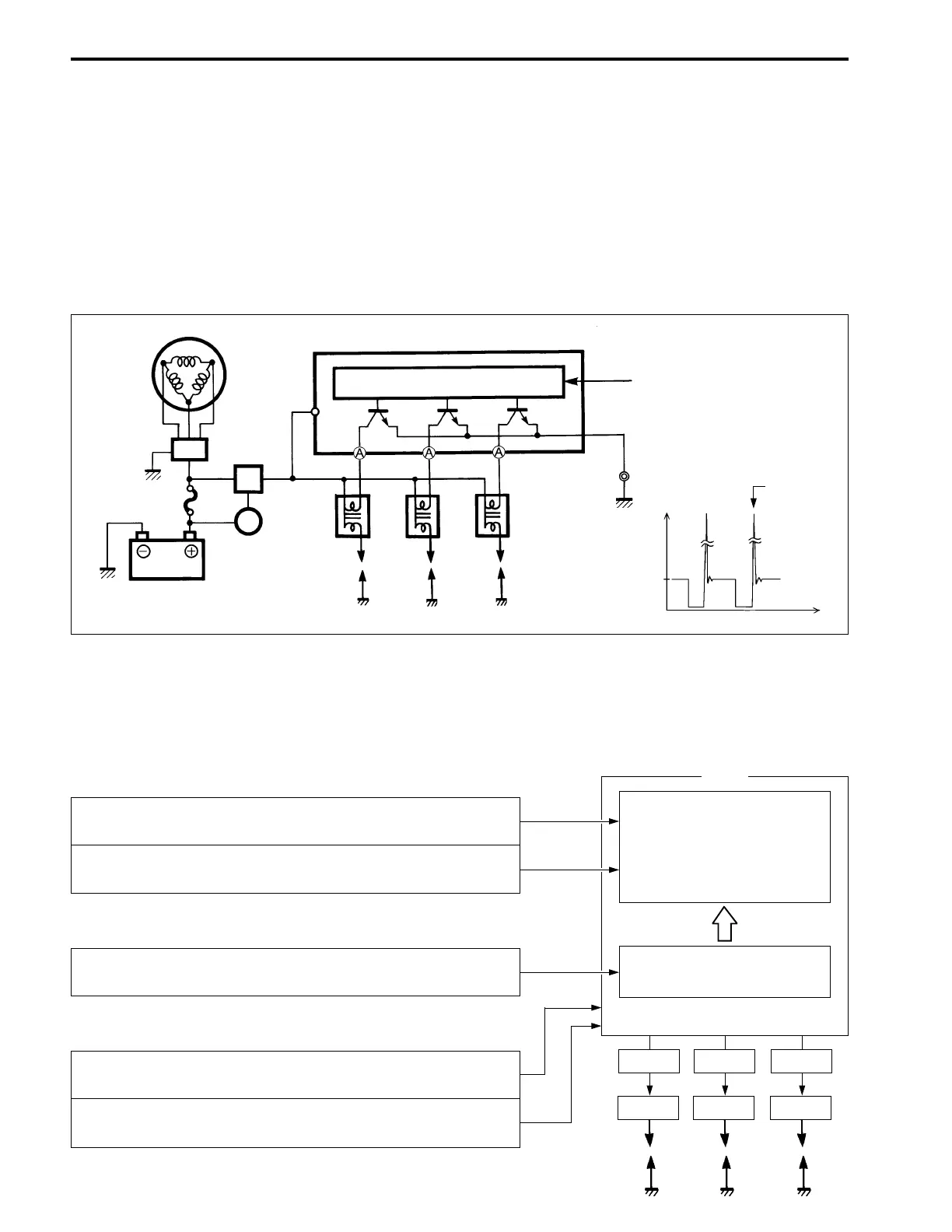

IGNITION SYSTEM

The ignition system used by the DF40/DF50 is a fully transistorized, electronic microcomputer timing ad-

vanced type.

On this system, power is totally supplied from the battery with the ECM controlling all ignition timing func-

tions.

The ignition system is composed of the ignition coil, spark plug and components for system control (ECM,

sensor,switch etc.)

When the ignition switch is “ON”, battery voltage (12V) is applied to the circuit as shown in the illustration.

At the calculated time of ignition, the transistor in the ECM turns “OFF”, breaking the ground circuit.

In this way, a mutual induction high voltage occurs in the ignition coil secondary side and spark is generated.

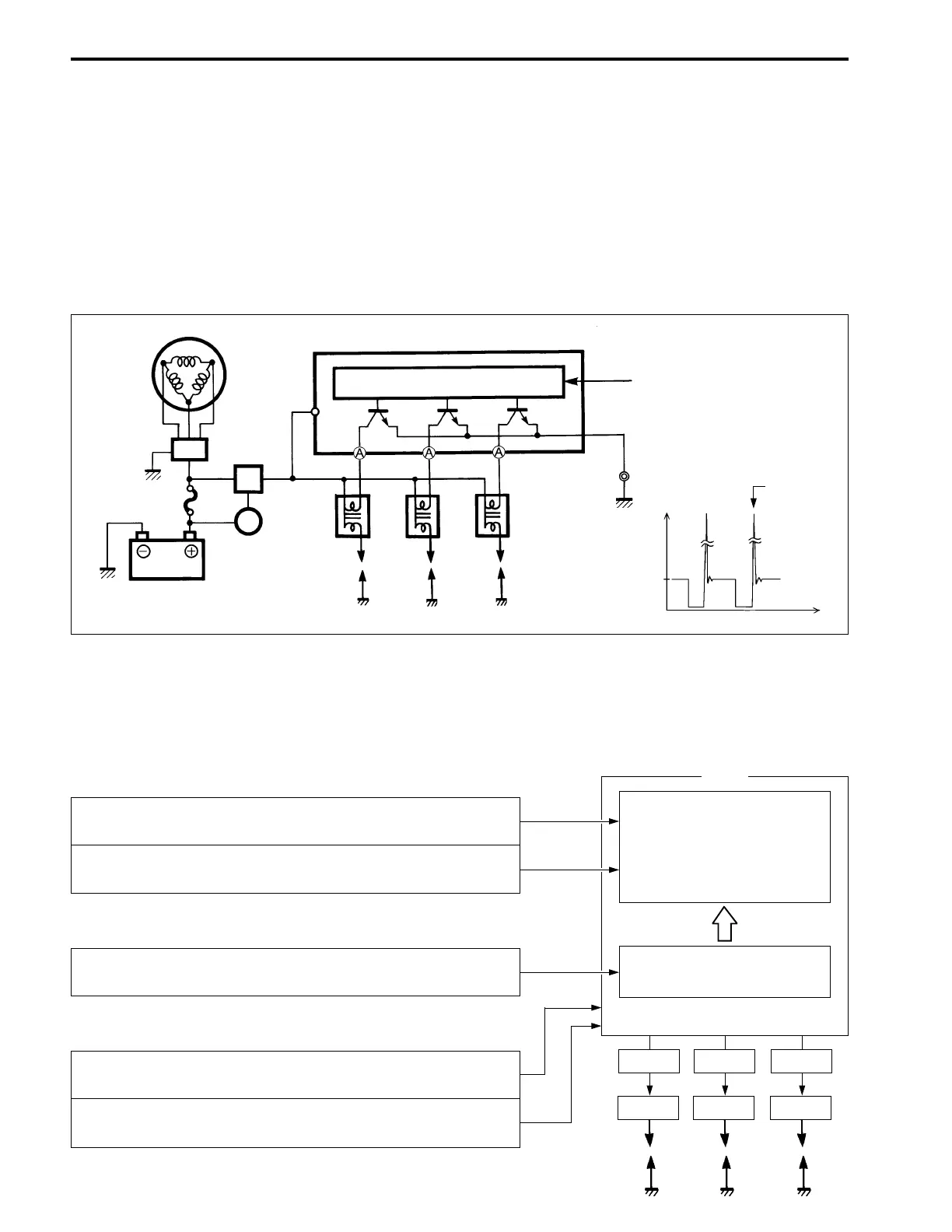

Basic sensors

Compensating sensors

Switches

Spark plug

MAP sensor :

Informs ECM of intake manifold pressure.

CKP sensor :

Informs ECM of engine speed and crankshaft angle.

Cylinder temperature sensor :

Informs ECM of cylinder temperature.

CTP switch :

Informs ECM of throttle position (open / closed).

Ignition switch :

Informs ECM of “START” signal.

Ignition timing is deter-

mined by a digital map de-

signed in relation to intake

manifold pressure and en-

gine speed.

ECM

Ignition timing compensa-

tion.

Signal

Ign.coil

Signal

Ign.coil

Signal

Ign.coil

(Voltage)

Spark timing

12V

A terminal voltage

(Time)

Sensor/switch

signal input

ECM

CPU

ECM

main

relay

Ignition

switch

Battery

30A fuse

Rectifier &

regulator

Battery

charge

coil

Ignition

coil

Spark

plug

Loading...

Loading...