3-33 ENGINE CONTROL SYSTEM

INSPECTION

PRECAUTION ON SYSTEM INSPECTION

A

To prevent an unexpected engine start, perform the following before proceeding with any CRANK-

ING tests.

• When performing tests not related to fuel injector operation :

• Disconnect all fuel injector wire connectors.

• When performing tests related to fuel injector operation :

• Relieve fuel pressure in line. (See page 5-2.)

• Disconnect high pressure fuel pump wire connector located on fuel vapor separator.

B

• Always turn ignition switch “OFF” and disconnect battery cables when wires are being discon-

nected or connected.

• Hold and pull connector pieces when disconnecting. Do not pull wires.

NOTE:

• The self-diagnostic code memory in ECM will remain even if battery is disconnected.

• As each terminal voltage is affected by battery voltage, use a full-charged battery.

• Make sure all ground points have good electrical contact.

• Make sure all wires/cables are securely connected.

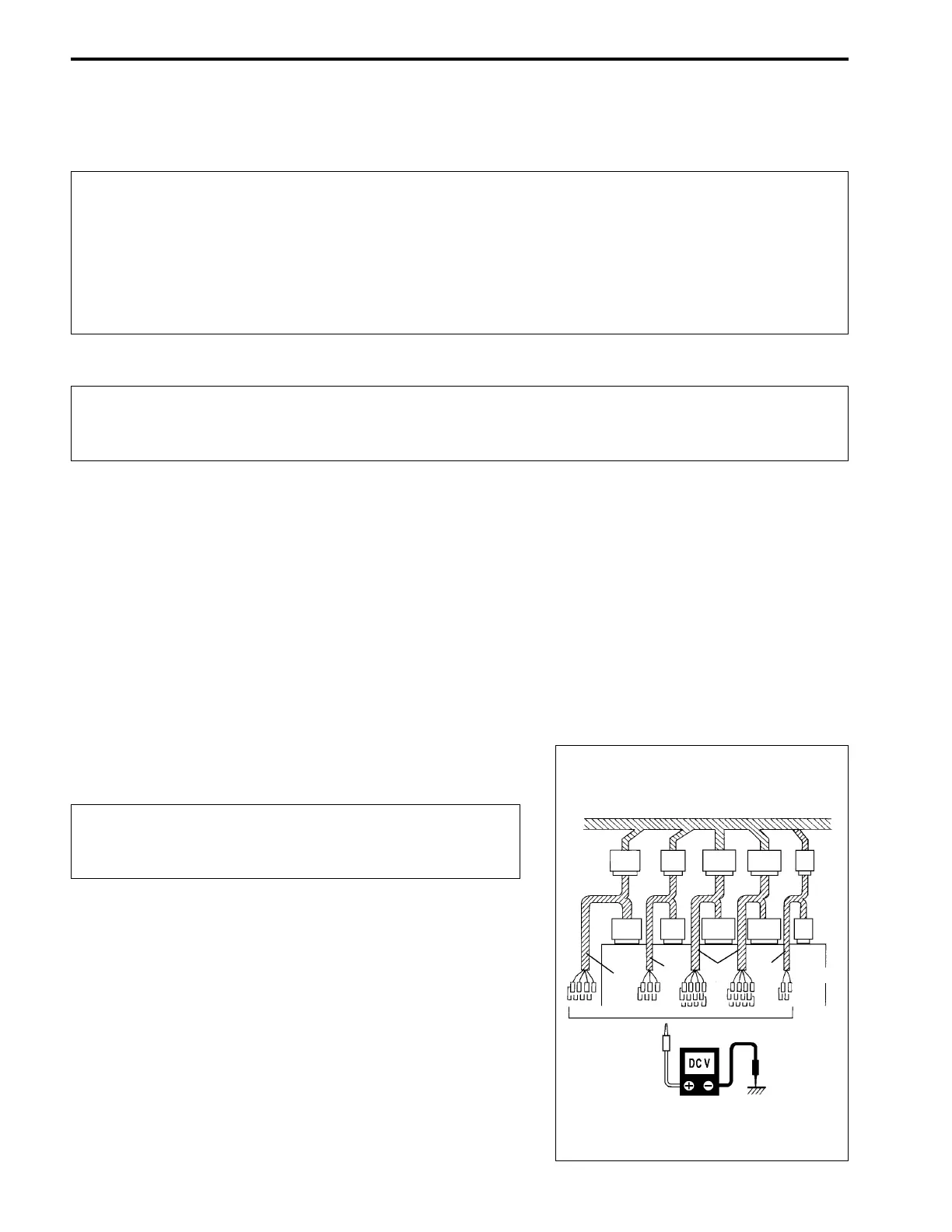

INSPECTION FOR ECM CIRCUIT VOLTAGE

B

ECM cannot be bench checked. It is strictly prohibited

to connect any tester (voltmeter or ohmmeter) to an

ECM separated from the engine wiring harness.

09930-89910 : 4-pin test cord – 1

09930-89920 : 6-pin test cord – 2

09930-89930 : 8-pin test cord – 3

09930-89940 : 12-pin test cord – 4

09930-99320 : Digital tester

Tester range :

--

--

- V (DC voltage)

(1) Turn ignition switch OFF.

(2) Connect the test cord 1,2,3 or 4 between ECM and wire

harness as shown.

(3) Connect the tester probe - (Black) to body ground, and

measure voltage according to the “CIRCUIT VOLTAGE

TABLE”.

z

s

ECM

E

DC

B

A

1

4

2

3

Loading...

Loading...