W

whitemichaelAug 21, 2025

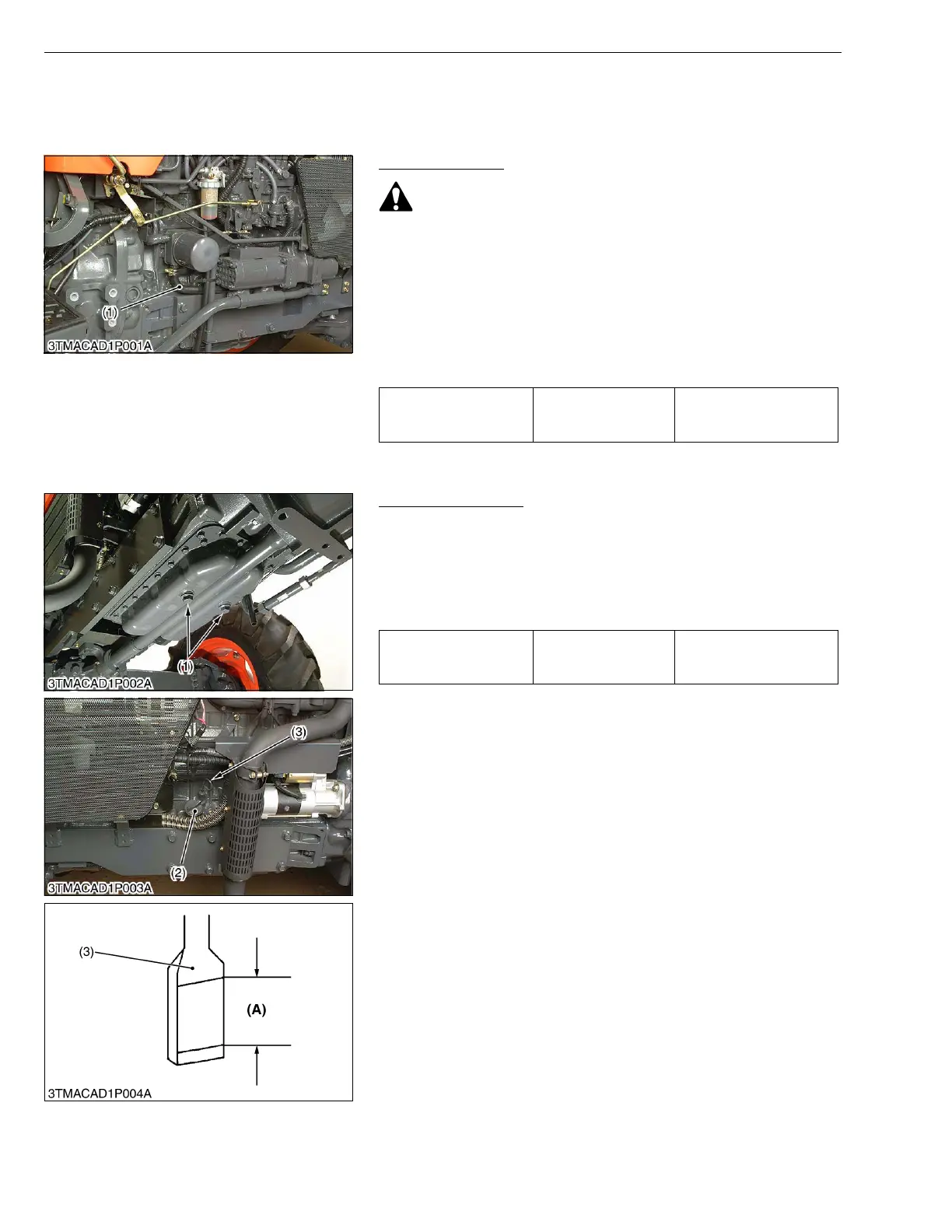

What to do if my wsm ME8200 engine is overheating?

- GGary DorseyAug 21, 2025

If your wsm Tractor engine is overheating, check the following: * Ensure there is sufficient engine oil and coolant; replenish if needed. * Inspect the fan belt for breakage or elongation; replace or adjust accordingly. * Clean any dust from the radiator net and fins, and address any corrosion inside the radiator or coolant flow route by cleaning or replacing the affected parts. * Replace a defective radiator cap. * Reduce the load if you are running with overload. * Replace a defective head gasket. * Adjust incorrect injection timing. * Use specified fuel if unsuitable fuel is used.