8-M25

ME8200, ME9000, WSM

HYDRAULIC SYSTEM

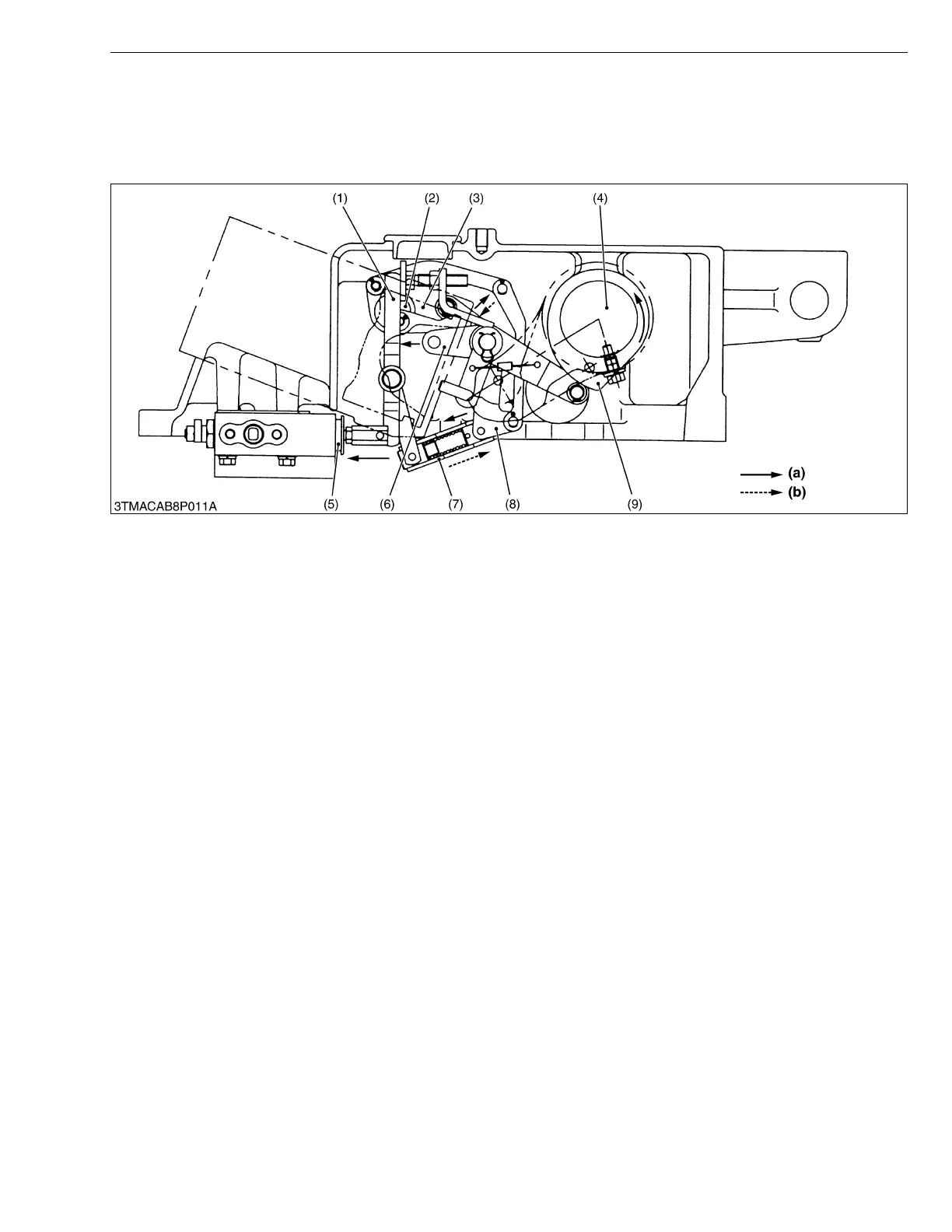

[2] POSITION CONTROL

Position control is a system to raise and lower the implement proportionally to the movement of the position control

lever. With this system, the implement can be raised or lowered to any position desired by changing the position of

the control lever and fine adjustment is also easy. When using the position control, the draft control lever should be

set to the lowest position.

■ Raising

1. When the position control lever is moved to the Raising direction, the position control shaft (2) rotates clockwise

to move the position connector (3) to the left.

2. Since the position balancer (6) is prevented by the position cam (9) from moving, the connector (8) rotates

clockwise as the position connector (3) moves. Thereby the holder (7) and spool retainer (1) are pushed against

the spool (5), and the spool (5) is forced in the control valve. As a result, a Raising circuit is formed.

3. When the lift arm moves upward, the hydraulic arm shaft (4) and position cam (9) rotate counterclockwise. As a

result, the position balancer (6) is also rotated counterclockwise. Accordingly, as the connector (8) does not press

the spool retainer (1), the spool (5) is forced out by the return spring in the control valve (feedback mechanism).

4. When the spool (5) returns to the neutral position, the lift arms stop rising. This results in raising of the lift arm in

proportion to the movement of the position control lever.

■ Lowering

1. When the control lever is moved to the Lowering direction, the position control shaft (2) rotates counterclockwise

to move the position connector (3) to the right.

2. As the position connector (3) moves, the connector (8) does not press the spool retainer (1) and the spool (5) is

forced out by the return spring in the control valve. As a result, a Lowering circuit is formed.

3. When the lift arms move downward, the hydraulic arm shaft (4) and position cam (9) rotate clockwise, causing the

position balancer (6) and connector (8) to press the holder (7) and spool retainer (1). Thereby, the spool (5) is

forced in (feedback mechanism).

4. When the spool (5) returns to the neutral position, the lift arms stop rising. This results in lowering of the lift arms

in proportion to the movement of the position control lever.

(1) Spool Retainer

(2) Position Control Shaft

(3) Position Connector

(4) Hydraulic Arm Shaft

(5) Spool

(6) Position Balancer

(7) Holder

(8) Connector

(9) Position Cam

(a) Motion for Raising

(b) Motion for Feedback