1-S70

ME8200, ME9000, WSM

ENGINE

[5] FUEL SYSTEM

(1) Checking and Adjusting

(A) Injection Pump

Injection Timing

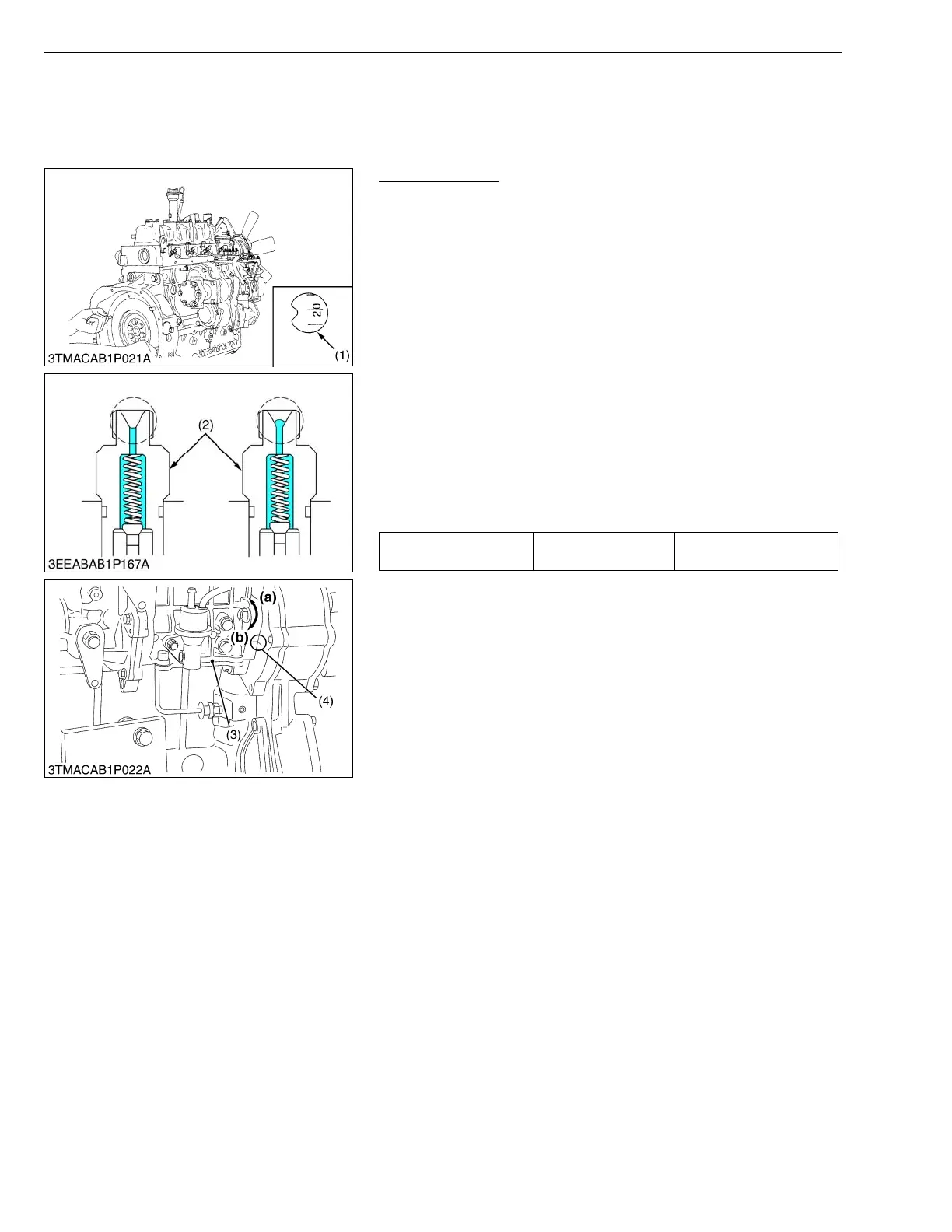

1. Remove the injection pipes.

2. Set the speed control lever to maximum fuel discharge position.

3. Turn the flywheel counterclockwise (facing the flywheel) until the

fuel fills up to the hole of the delivery valve holder (2) for 1st

cylinder.

4. Turn the flywheel further and stop turning when the fuel begins to

come up, to get the present injection timing.

5. The flywheel has mark 1TC and four lines indicating every 0.087

rad (5 °) of crank angle from 0.175 rad (10 °) to 0.349 rad (20 °)

before mark 1TC.

Calculate the angle which the projection of the window points out.

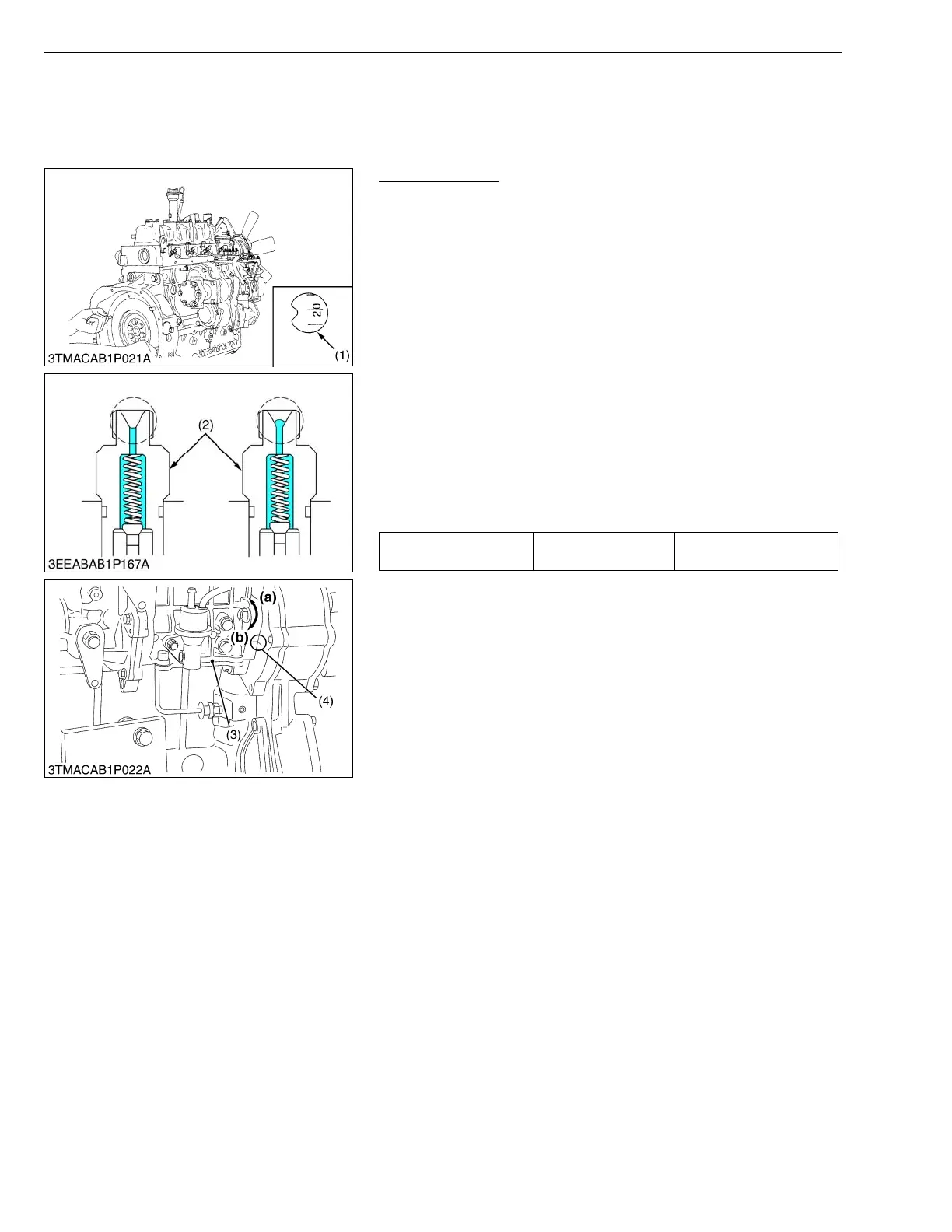

If the calculation differs from specified injection timing, rotate the

injection pump assembly to adjust the injection timing.

• Correct positioning of the injection pump is important for

proper fuel injection timing.

Match the marking (4) of the injection pump and that of the

gear case, as shown in the figure.

W1043581

Injection timing Factory spec.

0.26 to 0.30 rad (15 to 17 °)

before T.D.C.

(1) Timing Window

(2) Delivery Valve Holder

(3) Injection Pump

(4) Alignment Mark

(a) Injection Timing Advanced

(b) Injection Timing Delayed

Loading...

Loading...