8-S34

ME8200, ME9000, WSM

HYDRAULIC SYSTEM

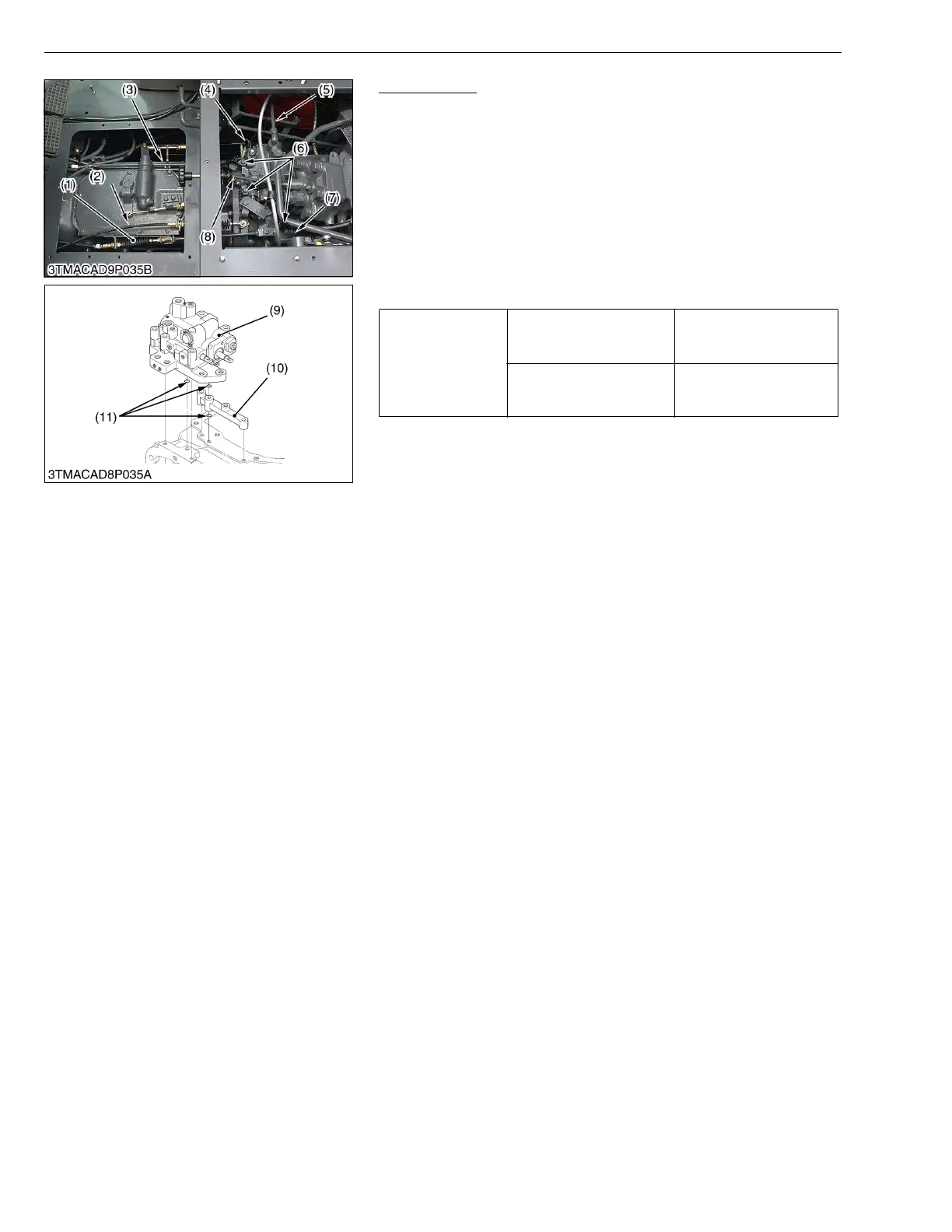

Shuttle Valve

1. Remove the lowering speed adjusting rod (8).

2. Remove the spring (7) and disconnect the clutch rod (1).

3. Disconnect the shuttle rod (2).

4. Disconnect the lead wire (4).

5. Disconnect the PTO shuttle pipe (5) and shuttle pipe (3).

6. Unscrew the screws (6) and remove the shuttle valve (9) with

shuttle base (10).

(When reassembling)

• Be sure to fit the O-rings (8).

• Be sure to adjust the neutral position. (See page 8-S11.)

• Be sure to adjust the clutch pedal free travel. (See page 2-S6.)

W1026962

(2) Master Cylinder and Equalizer

■ Precautions of Disassembling and Assembling for Hydraulic

Brake

• Wash all parts with clean brake oil (Specified oil : see page G-8).

• Before assembling the cylinder cups and O-rings, immerse them

in clean brake oil or apply silicon grease to them.

Use only the brake oil or silicon grease, otherwise the cylinder

cups may be deteriorated.

• It is recommended to replace the cylinder cups and gaskets with

new ones.

• Check the cylinder port for clogging, the inner surface of cylinder

and piston sliding part for damage, wear and rust, the spacer for

breakage and deformation, the return spring for fatigue and rust.

If any defect is found, replace.

W1027433

Tightening torque

Shuttle pipe eye joint bolt

39.2 to 45.0 N·m

4.0 to 4.6 kgf·m

29.0 to 33.2 lbf·ft

Shuttle valve mounting

screw M7 grade

23.5 to 27.5 N·m

2.4 to 2.8 kgf·m

17.4 to 20.3 lbf·ft

(1) Clutch Rod

(2) Shuttle Wire

(3) Shuttle Pipe

(4) Lead Wire

(5) PTO Shuttle Pipe

(6) Screw

(7) Spring

(8) Lowering Speed Adjusting Rod

(9) Shuttle Valve

(10) Shuttle Base

(11) O-ring