1-S24

ME8200, ME9000, WSM

ENGINE

(2) Disassembling and Assembling

(A) Cylinder Head

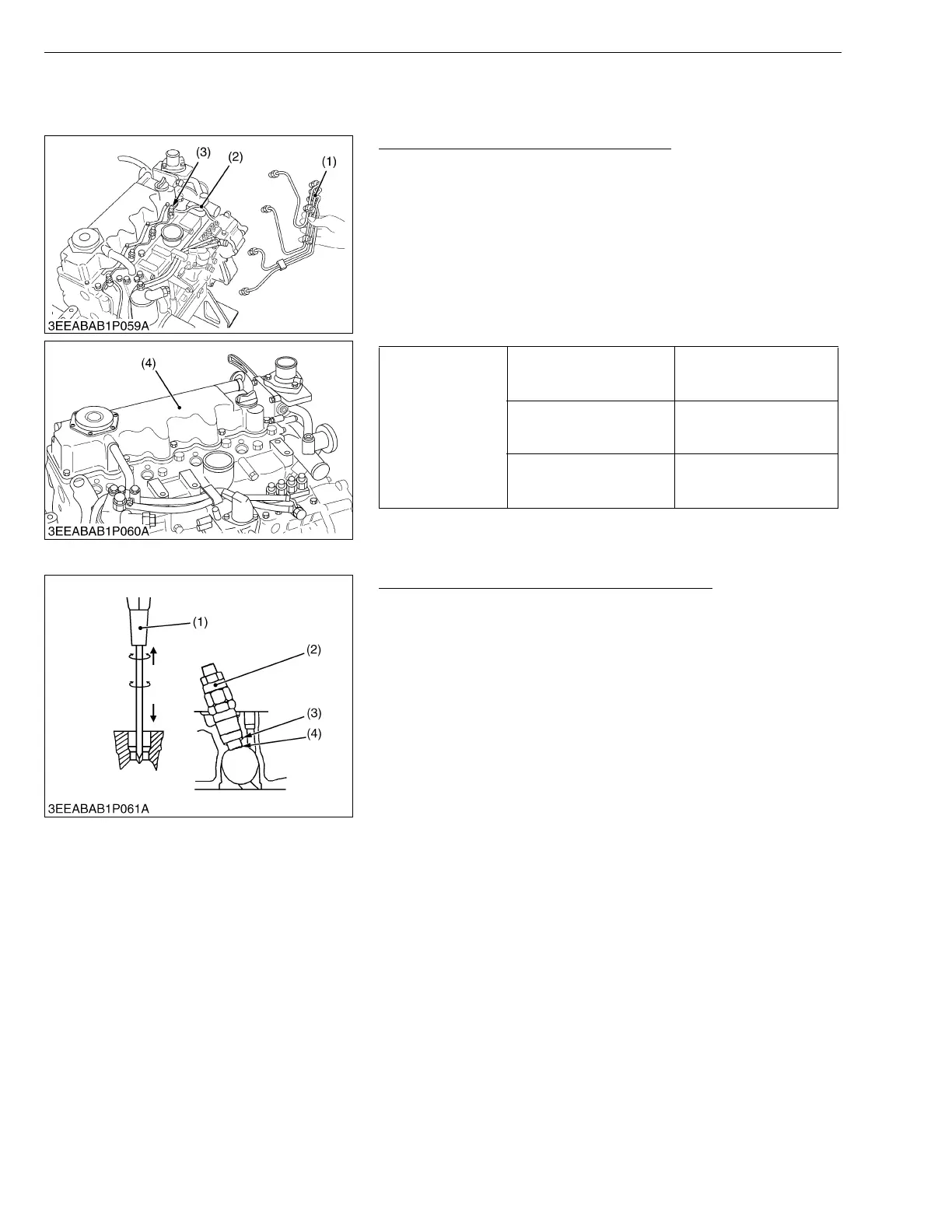

Cylinder Head Cover and Nozzle Holder

1. Remove the injection pipes (1) and overflow pipes (2).

2. Remove the glow plugs (3).

3. Remove the nozzle holder and copper gaskets.

4. Remove the heat seal.

5. Remove the head cover (4).

(When reassembling)

• Check to see that the cylinder head cover gasket is not defective.

• Be sure to place the heat seal.

• Tighten the head cover mounting bolts to specified torque.

• Mount the check valve with the ↓ mark toward the tank.

W1021020

Nozzle Heat Seal Service Removal Procedure

• Use a plus (phillips) screwdriver that has a dia. which is

bigger than the heat seal hole (Approx. 6 mm, 1/4 in.).

1. Drive screw driver lightly into the heat seal hole.

2. Turn screw driver three or four times each way.

3. While turning the screw driver, slowly pull the heat seal out

together with the injection nozzle gasket (3).

If the heat seal drops, repeat the above procedure. Heat seal (4)

and injection nozzle gasket (3) must be changed when the

injection nozzle is removed for cleaning or for service.

W1021356

Tightening torque

Cylinder head cover

mounting screw

6.9 to 11.3 N·m

0.7 to 1.15 kgf·m

5.1 to 8.32 lbf·ft

Injection pipe retaining nut

22.6 to 36.3 N·m

2.3 to 3.7 kgf·m

16.6 to 26.8 lbf·ft

Glow Plug

19.6 to 24.5 N·m

2.0 to 2.5 kgf·m

14.5 to 18.1 lbf·ft

(1) Injection Pipe

(2) Overflow Pipe

(3) Glow Plug

(4) Head Cover

(1) Plus Screw Driver

(2) Injection Nozzle

(3) Injection Nozzle Gasket

(4) Heat Seal