2-S15

ME8200, ME9000, WSM

CLUTCH

(2) Disassembling and Assembling

(A) PTO Clutch Valve

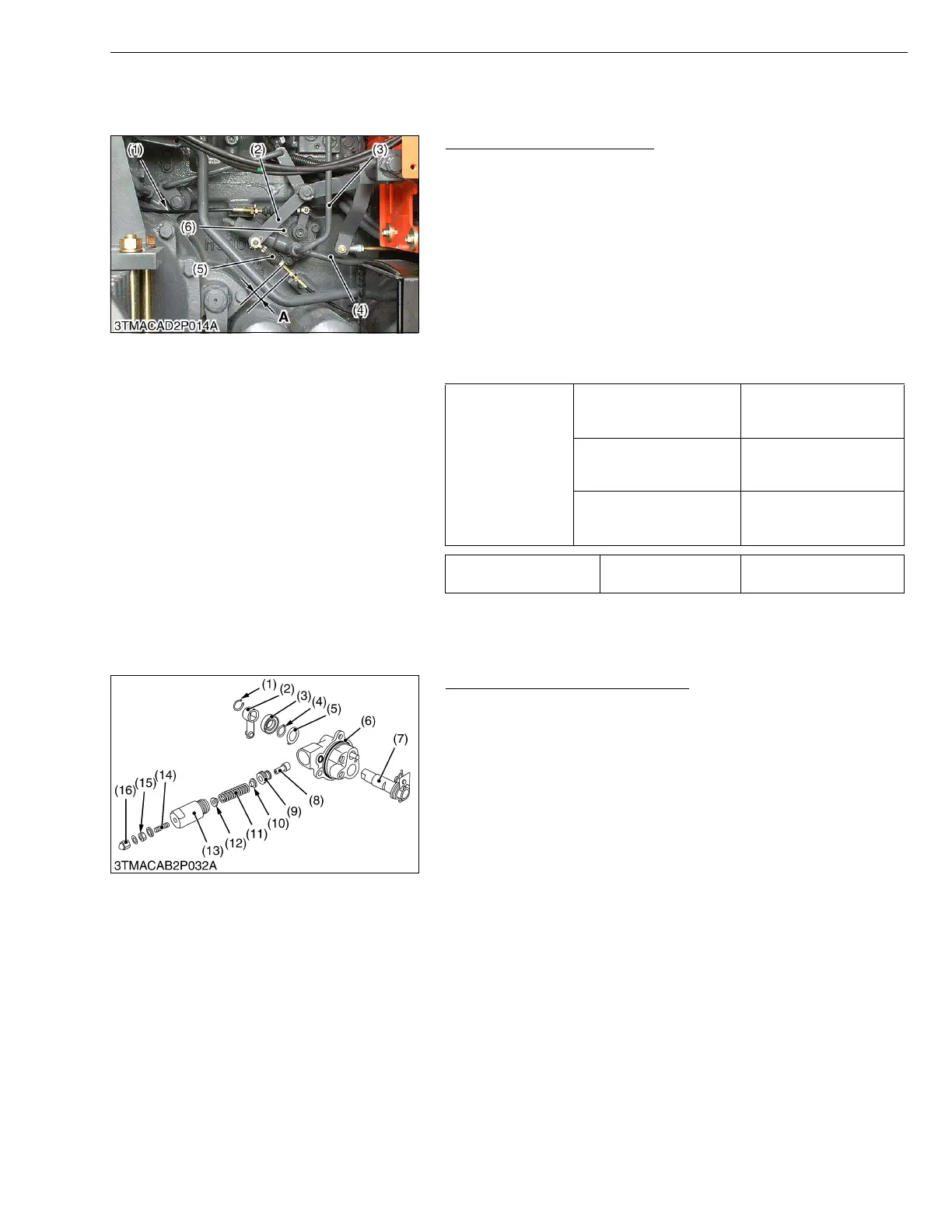

Removing PTO Clutch Valve

1. Remove the rear wheel (RH).

2. Disconnect the differential lock wire (5).

3. Remove the external snap ring for differential lock pedal (2).

(ROPS Type)

4. Remove the external snap ring for differential lock lever. (CABIN

Type)

5. Remove the PTO shuttle pipe (3) and PTO pipe (4).

6. Disconnect the PTO clutch cable (1) at PTO clutch valve side.

7. Remove the PTO clutch valve (6).

(When reassembling)

• Be sure to adjust the differential lock pedal free travel by

adjusting the length A.

W1018027

Disassembling PTO Clutch Valve

1. Remove the external snap ring (1), lever (2) and oil seal (3).

2. Remove the external snap ring (4) and draw out the spool (7).

3. Remove the cap nut (16) and lock nut (15).

4. Remove the adjuster (14) and relief body (13).

5. Draw out the relief poppet (8) and relief bush (9).

6. Draw out the spring (11) and spring seat (10), (12).

W1018379

Tightening torque

PTO clutch valve mounting

screw

23.5 to 27.5 N·m

2.4 to 2.8 kgf·m

17.4 to 20.3 lbf·ft

PTO shuttle pipe nut

49.0 to 68.6 N·m

5.0 to 7.0 kgf·m

36.2 to 50.6 lbf·ft

Rear wheel mounting nut

260 to 304 N·m

26.5 to 31.0 kgf·m

192 to 224 lbf·ft

Differential lock pedal

(front) free travel

Factory spec.

20.0 to 30.0 mm

0.79 to 1.18 in.

(1) PTO Clutch Cable

(2) Differential Lock Pedal

(3) PTO Shuttle Pipe

(4) PTO Pipe

(5) Differential Lock Wire

(6) PTO Valve

(1) External Snap Ring

(2) Lever

(3) Oil Seal

(4) External Snap Ring

(5) Collar

(6) Control Valve Body

(7) Spool

(8) Relief Poppet

(9) Relief Bush

(10) spring Seat

(11) Spring

(12) Spring Seat

(13) Relief Body

(14) Adjuster

(15) Lock Nut

(16) Cap Nut