8-S43

ME8200, ME9000, WSM

HYDRAULIC SYSTEM

(6) Hydraulic Pump for Three Point Hydraulic System

• The hydraulic pump is precision machined and assembled : if disassembled once, it may be unable to

maintain its original performance. Therefore, when the hydraulic pump fails, replacement should be

carried out with the hydraulic pump assembled except when emergency repair is unavoidable.

• When repair is required, flow the disassembly and servicing procedures shown below with upmost care.

• Be sure to test hydraulic pump with a flowmeter before disassembling.

• After reassembly, be sure to perform break-in operation and ensure that there is nothing abnormal with

the hydraulic pump.

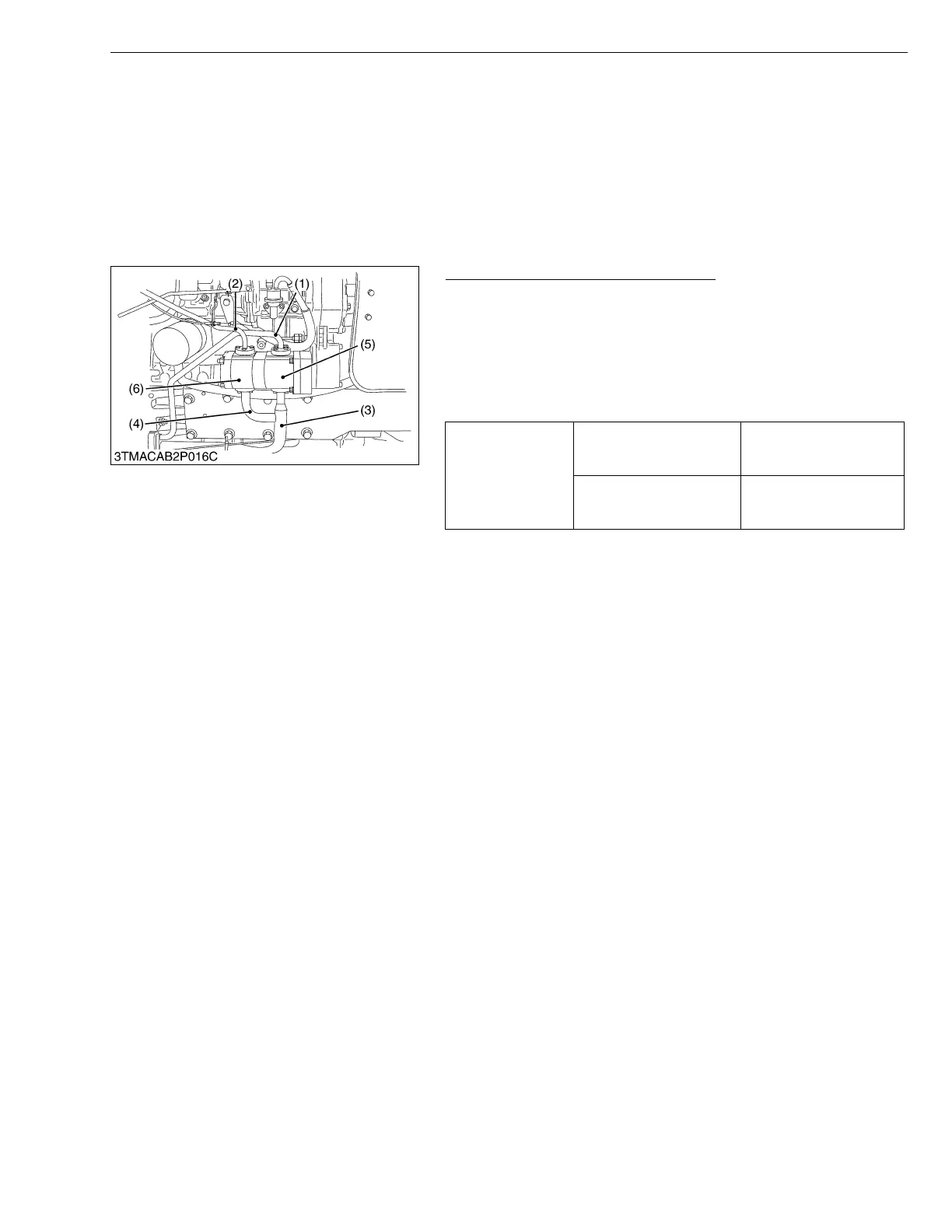

Removing Hydraulic Pump (ME8200)

1. Disconnect the delivery pipe (1), (2) from the hydraulic pump.

2. Disconnect the suction pipe (3), (4) from the hydraulic pump.

3. Remove the hydraulic pump assembly mounting screws and

nuts.

4. Take out the hydraulic pump assembly.

(When reassembling)

• Apply grease to the O-ring and take care not to damage it.

W1032807

Tightening torque

Hydraulic pipe mounting

screw

17.7 to 20.6 N·m

1.8 to 2.1 kgf·m

13.0 to 15.2 lbf·ft

Hydraulic pump assembly

mounting screw and nut

23.5 to 27.5 N·m

2.4 to 2.8 kgf·m

17.4 to 20.3 lbf·ft

(1) Delivery Pipe

(Three Point Hydraulic Pump)

(2) Delivery Pipe

(Power Steering Pump)

(3) Suction Pipe

(Three Point Hydraulic Pump)

(4) Suction Pipe (Power Steering Pump)

(5) Three Point Hydraulic Pump

(6) Power Steering Pump

Loading...

Loading...