8-S55

ME8200, ME9000, WSM

HYDRAULIC SYSTEM

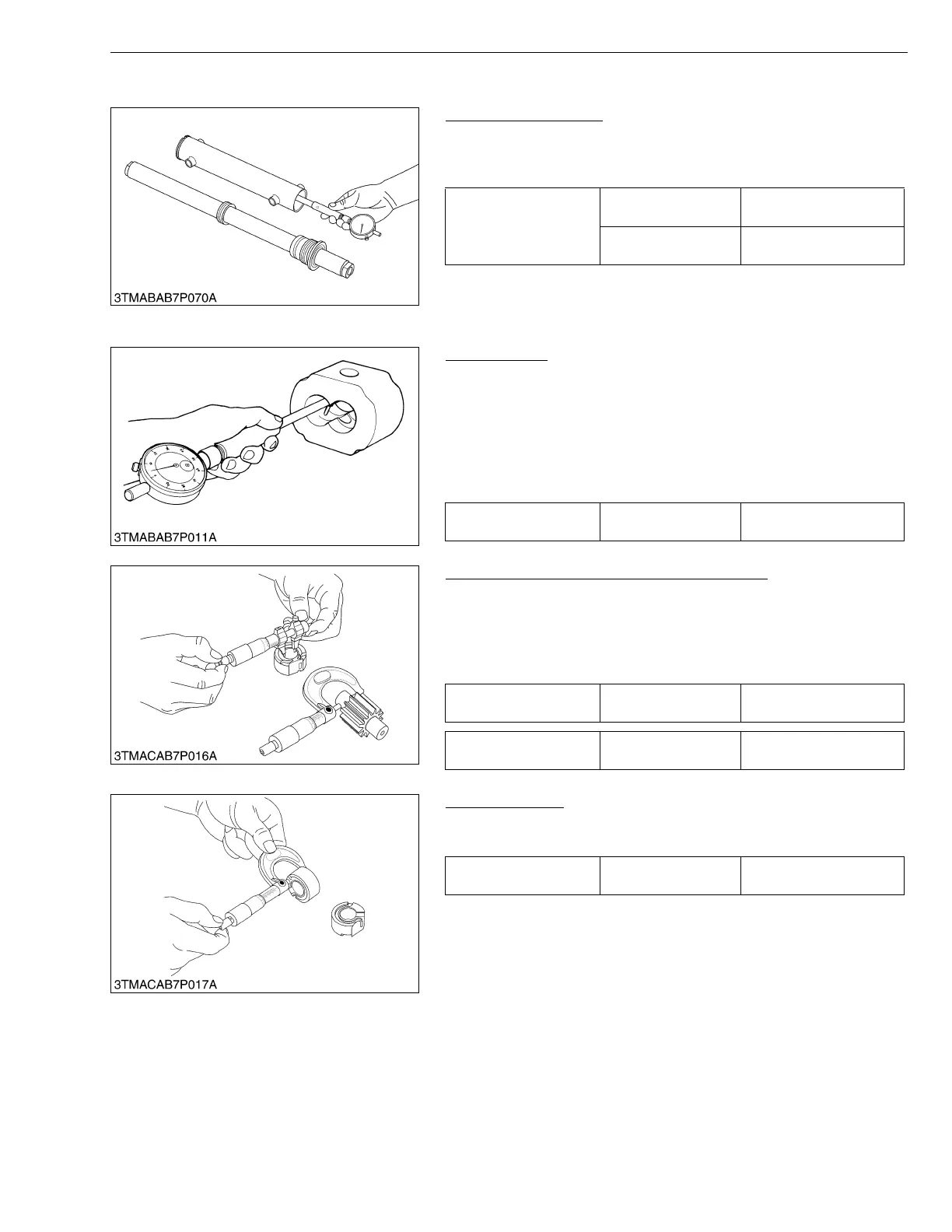

(2) Steering Cylinder

Steering Cylinder I.D.

1. Measure the steering cylinder I.D. with a cylinder gauge.

2. If the cylinder I.D. exceed the allowable limit, replace the cylinder

barrel.

W1017763

(3) Hydraulic Pump for Three Point Hydraulic System

Housing Bore

1. Measure the housing I.D. where the interior surface is not

scratched, and measure the housing I.D. where the interior

surface is scratched.

2. If the values obtained in the two determinations differ by more

than the allowable limit, replace the hydraulic pump as a unit.

(Reference)

• Use a cylinder gauge to measure the housing I.D..

W1013805

Clearance between Bushing and Gear Shaft

1. Measure the gear shaft O.D. with an outside micrometer.

2. Measure the bushing I.D. with an inside micrometer, and

calculate the clearance.

3. If the clearance exceeds the allowable limit, replace the gear

shaft and the bushing as a unit.

W1013925

Bushing Length

1. Measure the bushing length with an outside micrometer.

2. If the length is less than the allowable limit, replace it.

W1014047

Steering cylinder I.D.

Factory spec.

55.000 to 55.074 mm

2.16535 to 2.16827 in.

Allowable limit

55.100 mm

2.16929 in.

Depth of scratch Allowable limit

0.09 mm

0.0035 in.

Clearance between

bushing and gear shaft

Allowable limit

0.15 mm

0.0059 in.

Gear shaft O.D. Allowable limit

17.968 mm

0.7074 in.

Bushing length Allowable limit

18.965 mm

0.74665 in.