1-S72

ME8200, ME9000, WSM

ENGINE

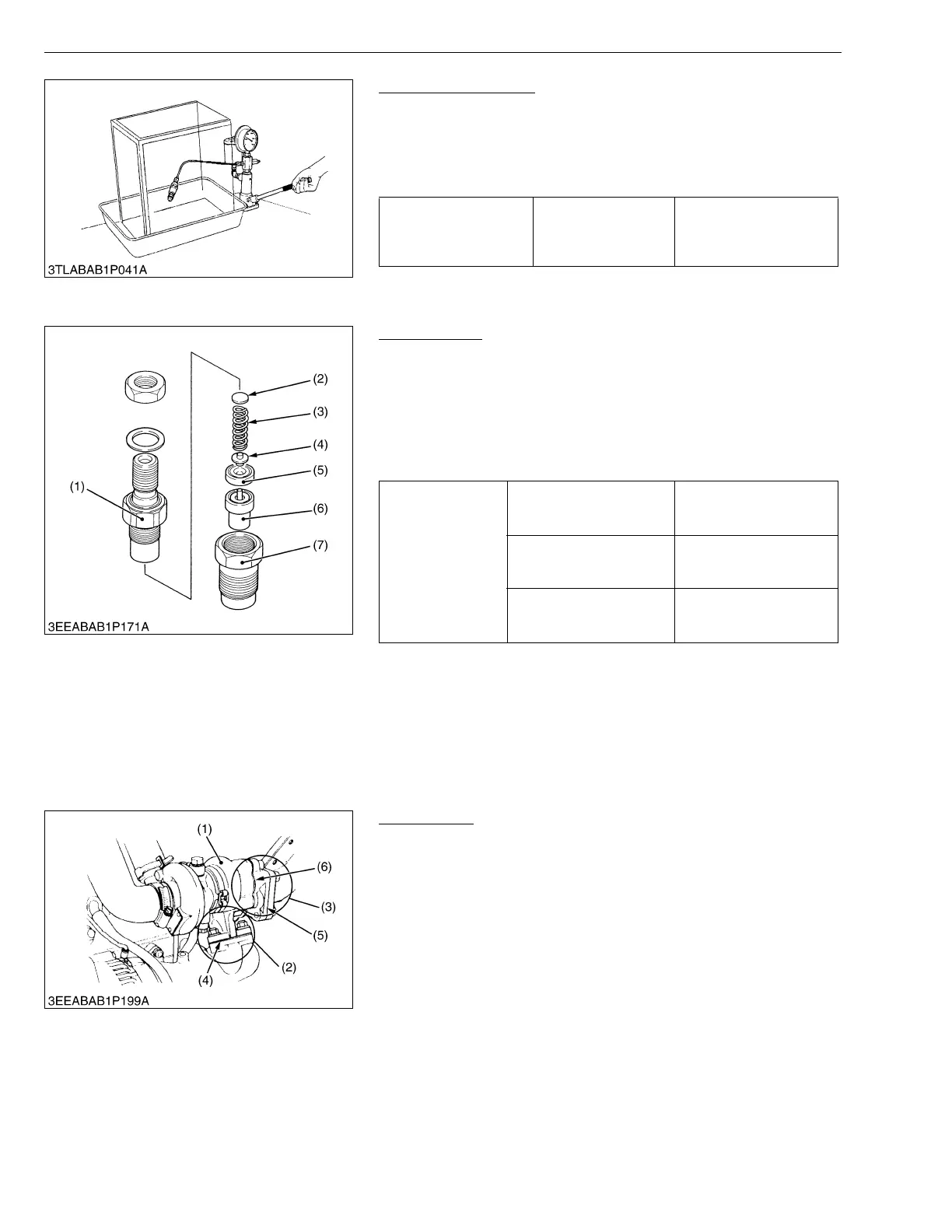

Valve Seat Tightness

1. Set the injection nozzle to a nozzle tester (Code No. 07909-

31361).

2. Raise the fuel pressure, and keep at 12.75 MPa (130 kgf/cm

2

,

1849 psi) for 10 seconds.

3. If any fuel leak is found, replace the nozzle piece.

W1044357

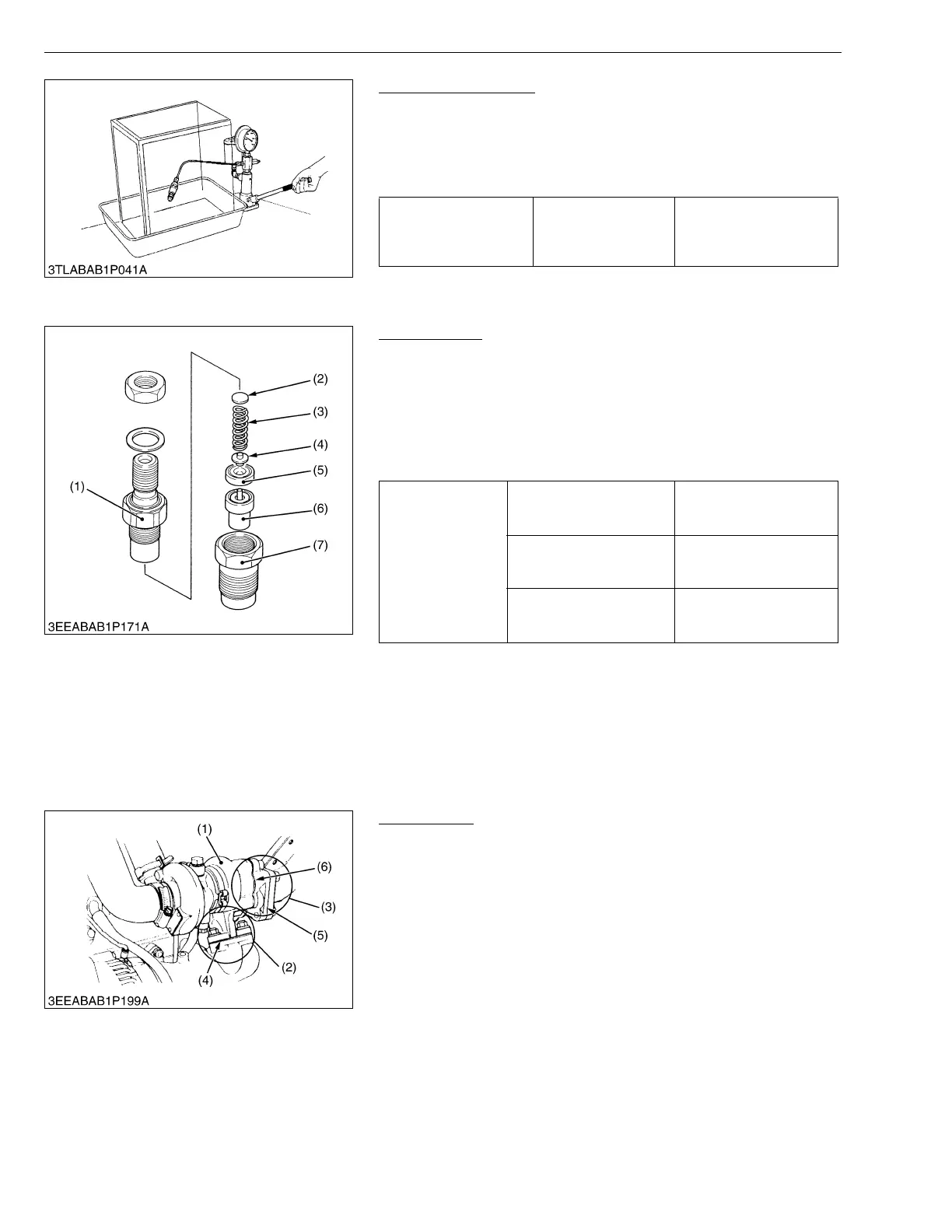

(2) Disassembling and Assembling

Nozzle Holder

1. Secure the nozzle retaining nut (7) with a vise.

2. Remove the nozzle holder (1), and take out parts inside.

(When reassembling)

• Assemble the nozzle in clean fuel oil.

• Install the push rod (4), noting its direction.

• After assembling the nozzle, be sure to adjust the fuel injection

pressure.

W1044500

[6] TURBOCHARGER SYSTEM

(1) Checking

Turbine Side

1. Check the exhaust port (3) and inlet port (2) side of turbine

housing (1) to see if there is no exhaust gas leak.

2. If any gas leak is found, retighten the bolts and nuts or replace

the gasket (4) / (5) / (6) with new one.

W1044873

Injection pressure Factory spec.

No fuel leak at

12.75 MPa

130 kgf/cm

2

1849 psi

Tightening torque

Nozzle holder

34.3 to 39.2 N·m

3.5 to 4.0 kgf·m

25.3 to 28.9 lbf·ft

Overflow pipe nut

19.6 to 24.5 N·m

2.0 to 2.5 kgf·m

14.5 to 18.1 lbf·ft

Nozzle holder assembly

49.0 to 68.6 N·m

5.0 to 7.0 kgf·m

36.2 to 50.6 lbf·ft

(1) Nozzle Holder

(2) Adjusting Washer

(3) Nozzle Spring

(4) Push Rod

(5) Distance Piece

(6) Nozzle Piece

(7) Nozzle Retaining Nut

(1) Turbine Housing

(2) Inlet Port

(3) Exhaust Port

(4) Gasket

(5) Gasket

(6) Gasket

Loading...

Loading...