153

Setup

Using the Movable Sensor

The movable sensor is a dual function sensor. It provides transmissive (sees through

media) and reflective media sensing. The printer can use either sensing method, but not

both at the same time.

The movable sensor has a center array of sensors. This provides adjustable transmissive

web (gap) sensing to positions that match legacy Zebra

®

desktop printer sensor locations

and positions in between. This also provides for use of some atypical media variations or

irregularly shaped media.

The movable sensor allows the printer to use media with black marks or notches (holes

through the media) on the back side of the media (or media liner). The sensor aligns to the

middle of black marks or notches not in the center of the media roll to avoid Web/Gap

sensing array.

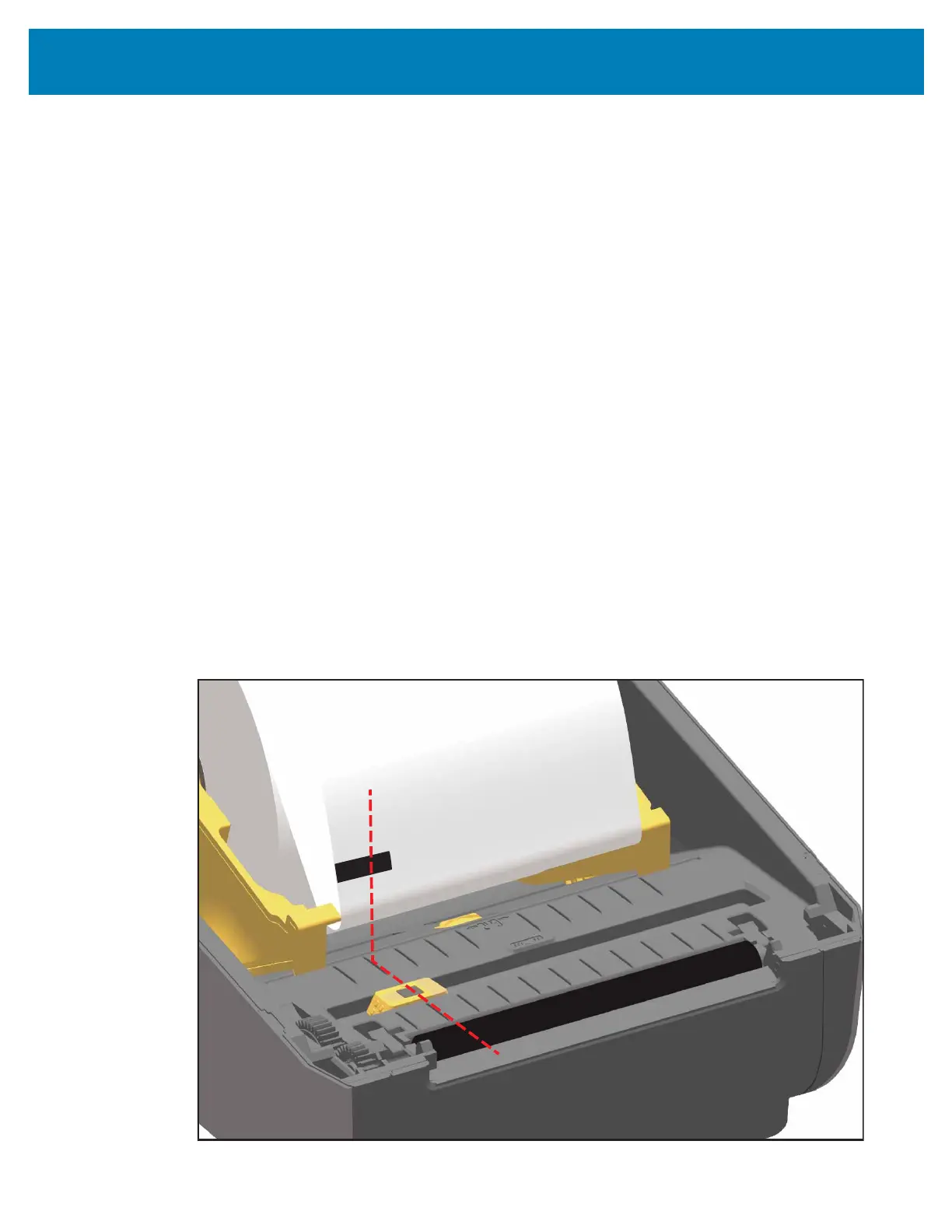

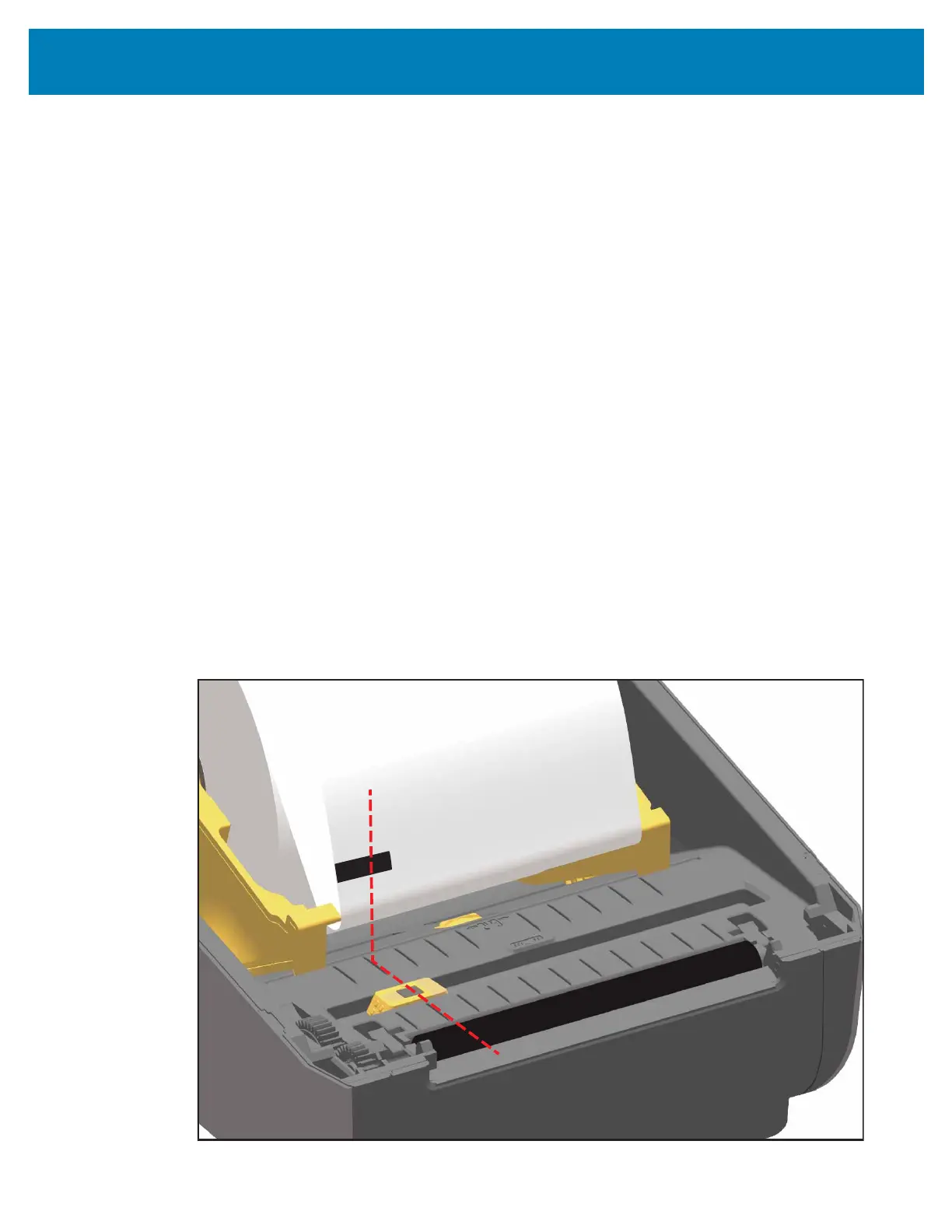

Adjusting the Movable Sensor for Black Marks or Notches

The black mark sensing looks for non-reflective surfaces such as black marks, black lines,

notches or holes on the back of the media which do not reflect the sensor’s near infrared

light beam back to the sensor’s detector. The sensor light and its black mark detector are

next to each other under the sensor cover.

Position the movable sensor’s alignment arrow to the middle of the black mark or notch in

the underside of the media. Sensor alignment should be set as far as possible from the

edge of media but where 100% of the sensor window is covered by the mark. When

printing, the media can move from side to side ±1mm (due to media variations and edge

damage due to handling). Notches cut into the side of the media can also become

damaged.

Loading...

Loading...