23.20

23 11 Checking and adjusting fully

assembled length of gearbox shafts

and selector drum

Checking and adjusting fully assembled length

of intermediate shaft

e Attention:

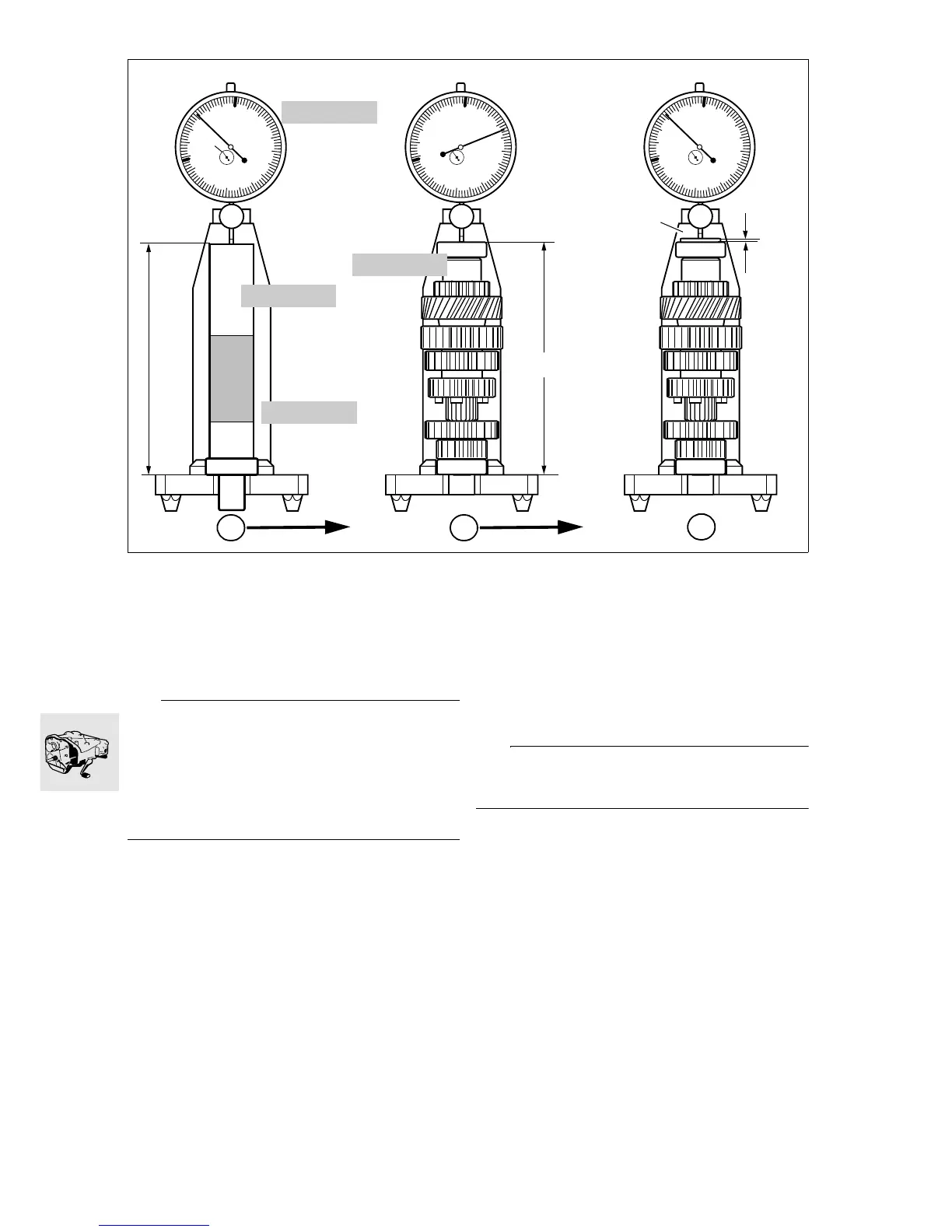

Check and adjust the fully assembled length as de-

scribed below and install a spacing washer of the

correct thickness.

Before measuring, always make sure that the

grooved ball bearings are pressed fully home, even

if the shaft has not been disassembled and reas-

sembled.

•

Position dial gauge, BMW No. 23 4 762, in rear

locating bore of stand, BMWNo.234761, and

set to 0.2 mm (0.0078 in) preload.

•

Using dial gauge, zero to dimension “A” of the

zero gauge, BMW No. 23 4 763.

•

Pull off the input-side grooved ball bearing with

universal puller, BMW No. 00 7 500.

•

Remove the spacing washer.

•

Place reference washer, BMWNo.234765, on

the intermediate shaft.

•

Place the grooved ball bearing on the reference

washer.

•

Insert intermediate shaft in measuring stand.

•

Using the dial gauge, measure the deviation from

zero of dimension “B” at

the inner bearing race.

Deviation from zero is equivalent to the thickness

“C” of spacer (1).

•

Place spacer (1) of correct thickness on

inner bearing race and check deviation from ze-

ro.

A = B + C

e Attention:

The maximum deviation from zero must not be ex-

ceeded.

•

Remove the intermediate shaft from the measur-

ing fixture.

•

Remove spacing washer, grooved ball bearing

and reference washer.

•

Place a spacing washer (1) of the correct thick-

ness on the intermediate shaft and press on the

grooved ball bearing.

Reference dimension for intermediate shaft:

The maximum permissible deviation from zero is

........................ -0.05…0.00 mm (-0.0019…0.00 in)

0

90

10

20

30

40

50

60

70

80

0

90

10

20

30

40

50

60

70

80

0

90

10

20

30

40

50

60

70

80

KR230181

23 4 763

23 4 761

23 4 762

23 4 765

0.2

1

3

2

1

C

B

A

Loading...

Loading...