31.8

•

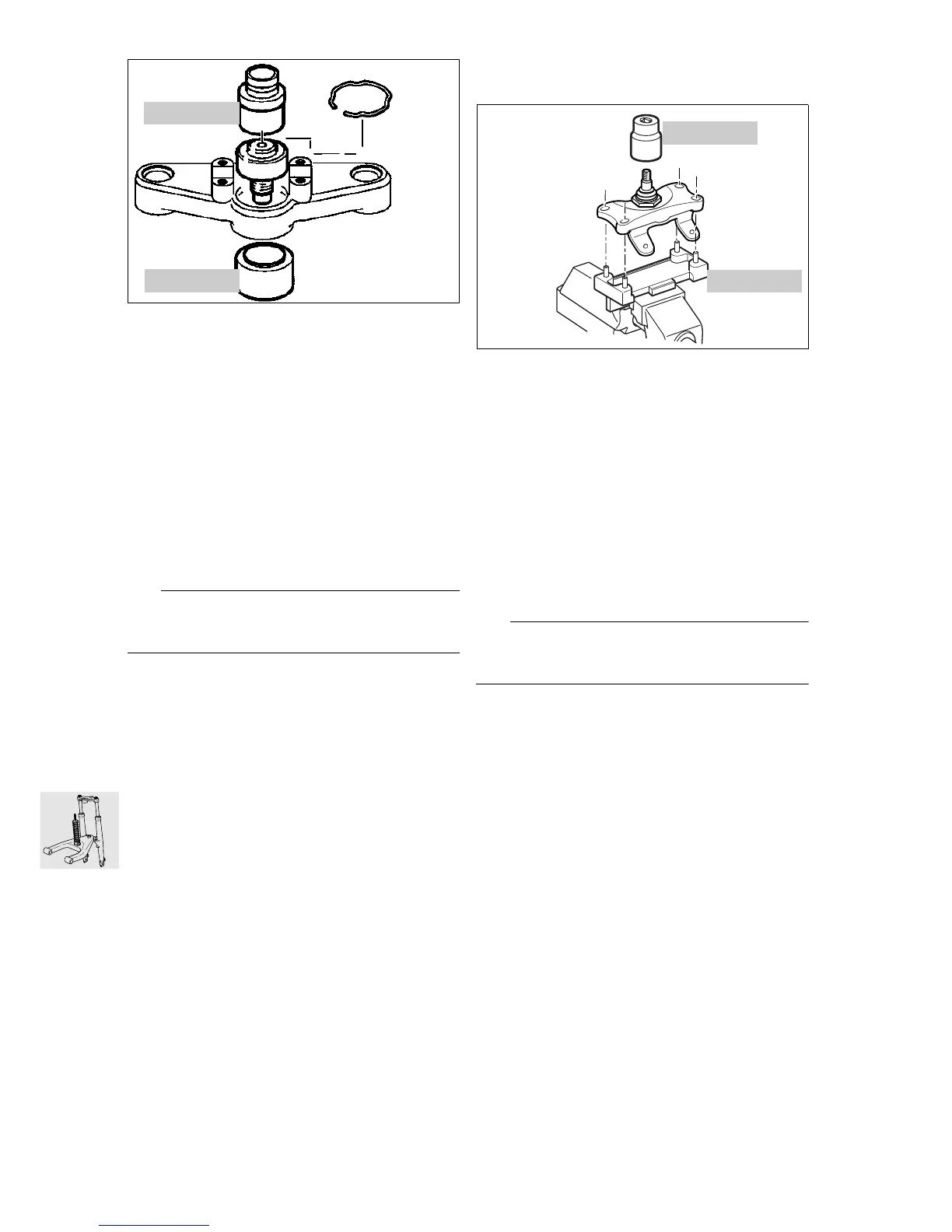

Heat the fork bridge to 100 °C (212 °F) and press

in the angular-contact ball bearing with pin,

BMW No. 31 5 651, and bushing,

BMW No. 31 5 653.

•

Install retaining ring.

31 42

Removing and installing slider

tube bridge

•

Remove mudguard.

•

Heat leading link mount at front to

max. 120 °C (248 °F) and unscrew.

•

Remove fastener securing slider tube bridge.

•

Installation is the reverse of the removal proce-

dure.

e Attention:

Comply with assembly instructions for telescopic

fork.

X Tightening torque:

Leading link to ball joint

(clean thread + Loctite 2701)...................... 130 Nm

Slider tube bridge to slider tube

(clean thread + Loctite 243)......................... 25 Nm

Removing and installing ball joint in slider tube

bridge

•

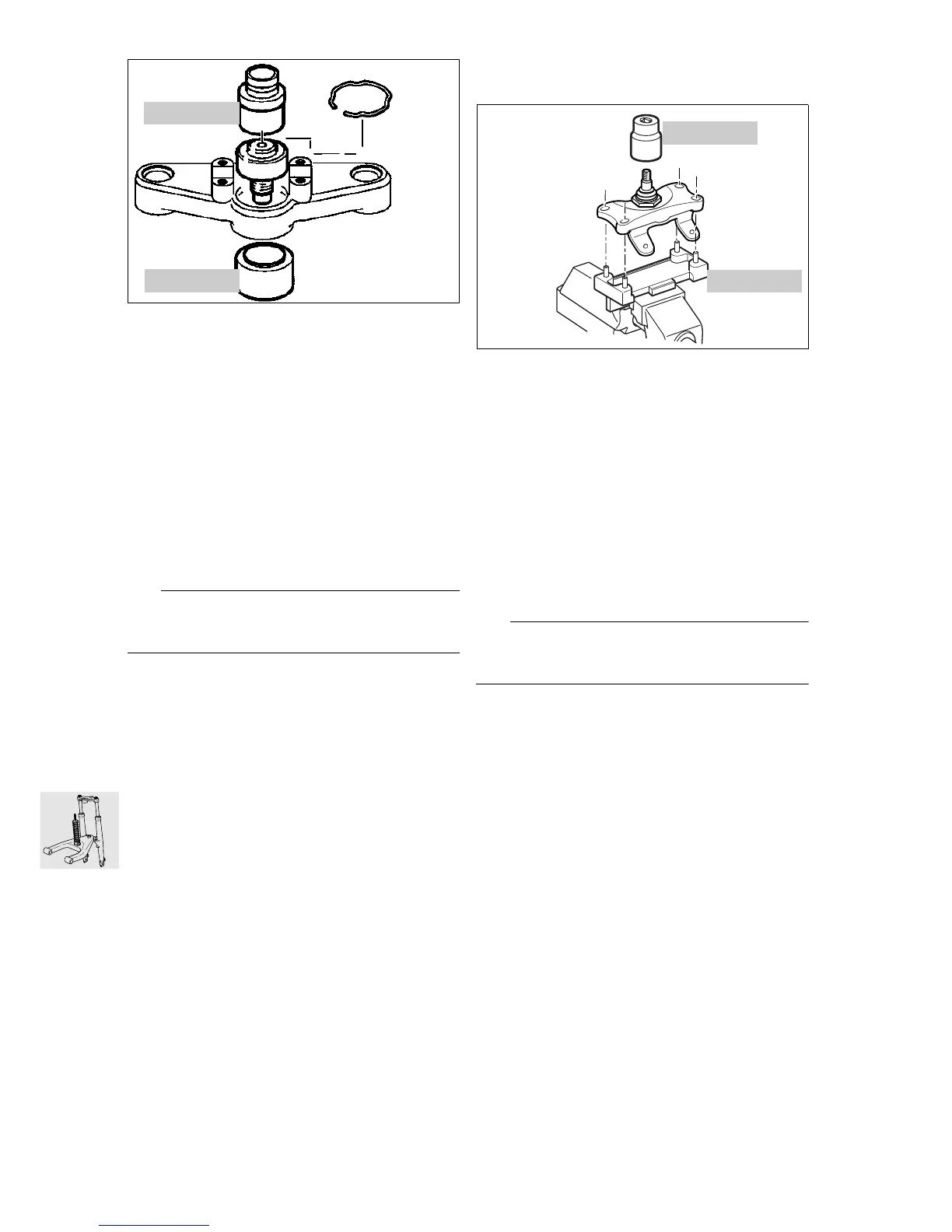

Mount the slider tube bridge in retaining fixture,

BMW No. 31 5 620.

•

Loosen and tighten ball joint with 46 mm socket,

BMW No. 31 5 630 .

X Tightening torque:

Ball joint to slider tube bridge

(coat threads with Optimoly TA).................. 230 Nm

31 42

Checking friction at ball joint/

angular-contact ball bearing

•

Raise the motorcycle on its main (centre) stand,

make sure front wheel is clear of the ground.

L Note:

To determine the friction value, increase torque very

slowly.

•

Measure the breakaway moment to left and right

from the central position of the handlebars using

friction meter, BMW No. 00 2 570.

Friction value:

Measure at room temperature (above 20 °C/68 °F)

Specified value:................................... 1.0...2.0 Nm

j

100

w

GS310130

31 5 653

31 5 651

R22310050

31 5 630

31 5 620

Loading...

Loading...