Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running

the motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL listing

information

102 Unidrive M702 User Guide

Issue Number: 3

7 Running the motor

This chapter takes the new user through all the essential steps to

running a motor for the first time, in each of the possible operating

modes.

For information on tuning the drive for the best performance, see

Chapter 8 Optimization on page 118.

7.1 Quick start connections

7.1.1 Basic requirements

This section shows the basic connections which must be made for the

drive to run in the required mode. For minimal parameter settings to run

in each mode please see the relevant part of section 7.3 Quick start

commissioning / start-up on page 107.

Table 7-1 Minimum control connection requirements for each

control mode

Table 7-2 Minimum control connection requirements for each

mode of operation

Speed feedback

Suitable devices are:

• Incremental encoder (A, B or F, D with or without Z)

• Incremental encoder with forward and reverse outputs (F, R with or

without Z)

• SINCOS encoder (with, or without Stegmann Hiperface, EnDat or

SSI communications protocols)

• BiSS absolute encoder

• EnDat absolute encoder

• Resolver

Speed and position feedback

Suitable devices are:

• Incremental encoder (A, B or F, D with or without Z) with

commutation signals (U, V, W)

• Incremental encoder with forward and reverse outputs (F, R with or

without Z) and commutation outputs (U, V, W)

• SINCOS encoder (with Stegmann Hiperface, EnDat or SSI

communications protocols)

• BiSS absolute encoder

• EnDat absolute encoder

• Resolver

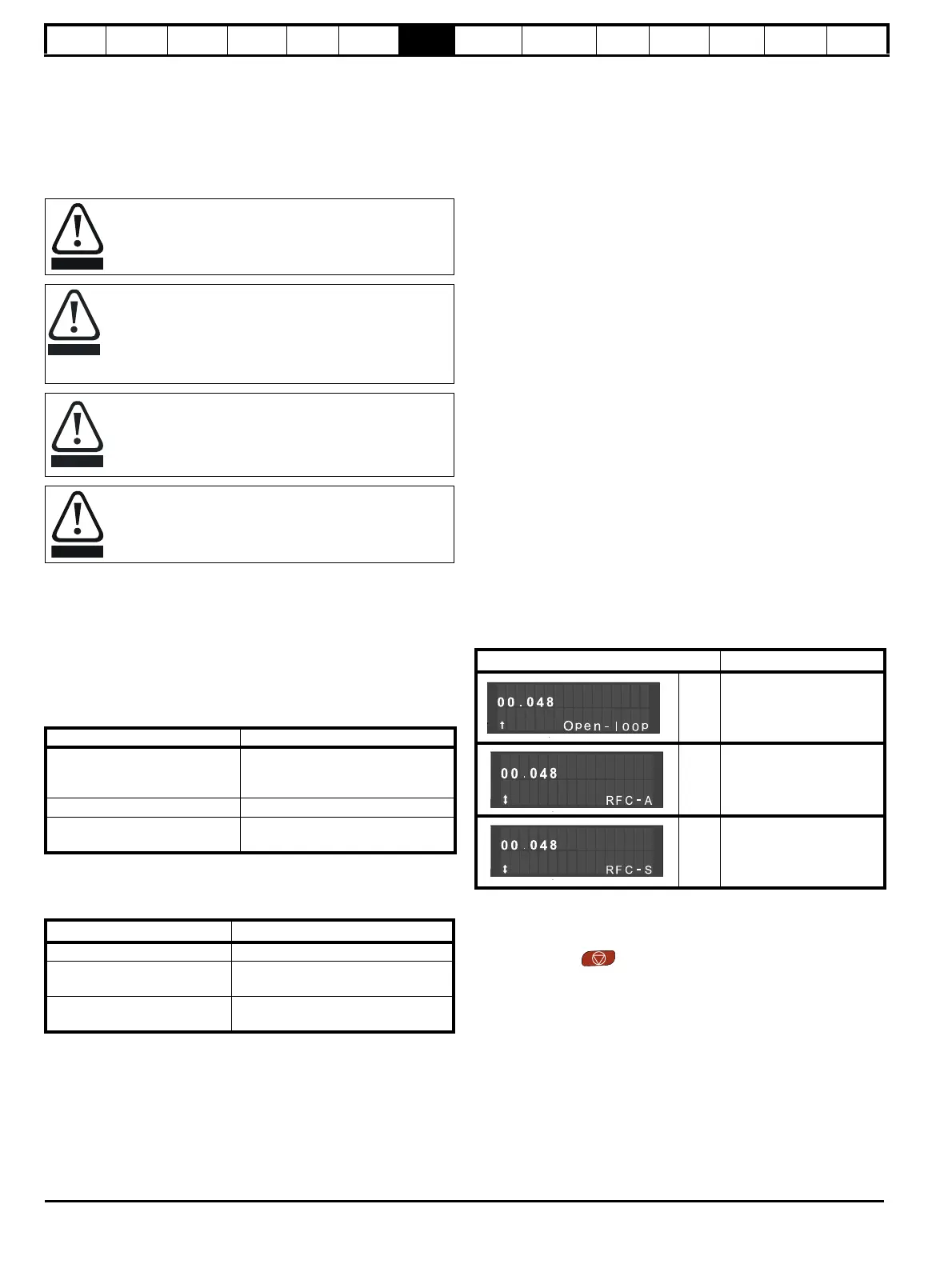

7.2 Changing the operating mode

Changing the operating mode returns all parameters to their default

value, including the motor parameters. User Security Status (Pr 00.049)

and User Security Code (Pr 00.034) are not affected by this procedure).

Procedure

Use the following procedure only if a different operating mode is

required:

1. Enter either of the following values in Pr mm.000, as appropriate:

1253 (50 Hz AC supply frequency)

1254 (60 Hz AC supply frequency)

2. Change the setting of Pr 00.048 as follows:

The figures in the second column apply when serial communications are

used.

3. Either:

• Press the red reset button

• Toggle the reset digital input

• Carry out a drive reset through serial communications by setting

Pr 10.038 to 100 (ensure that Pr. mm.000 returns to 0).

Ensure that no damage or safety hazard could arise from the

motor starting unexpectedly.

The values of the motor parameters affect the protection of

the motor.

The default values in the drive should not be relied upon.

It is essential that the correct value is entered in Pr 00.046

Rated Current. This affects the thermal protection of the

motor.

If the drive is started using the keypad it will run to the speed

defined by the keypad reference (Pr 01.017). This may not

be acceptable depending on the application. The user must

check in Pr 01.017 and ensure that the keypad reference

has been set to 0.

If the intended maximum speed affects the safety of the

machinery, additional independent over-speed protection

must be used.

Drive control method Requirements

Terminal mode

Drive enable

Speed / Torque reference

Run forward / Run reverse

Keypad mode Drive enable

Serial communications

Drive enable

Serial communications link

Operating mode Requirements

Open loop mode Induction motor

RFC – A mode

(with speed feedback)

Induction motor with speed feedback

RFC – S mode (with speed and

position feedback)

Permanent magnet motor with speed

and position feedback

Pr 00.048 setting Operating mode

1 Open-loop

2RFC-A

3RFC-S

Loading...

Loading...