Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running

the motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL listing

information

Unidrive M702 User Guide 39

Issue Number: 3

3.6.3 Enclosure sizing

1. Add the dissipation figures from section 12.1.2 Power dissipation on

page 232 for each drive that is to be installed in the enclosure.

2. If an external EMC filter is to be used with each drive, add the

dissipation figures from section 12.2.1 EMC filter ratings on

page 245 for each external EMC filter that is to be installed in the

enclosure.

3. If the braking resistor is to be mounted inside the enclosure, add the

average power figures from for each braking resistor that is to be

installed in the enclosure.

4. Calculate the total heat dissipation (in Watts) of any other equipment

to be installed in the enclosure.

5. Add the heat dissipation figures obtained above. This gives a figure

in Watts for the total heat that will be dissipated inside the enclosure.

Calculating the size of a sealed enclosure

The enclosure transfers internally generated heat into the surrounding

air by natural convection (or external forced air flow); the greater the

surface area of the enclosure walls, the better is the dissipation

capability. Only the surfaces of the enclosure that are unobstructed (not

in contact with a wall or floor) can dissipate heat.

Calculate the minimum required unobstructed surface area A

e

for the

enclosure from:

Where:

A

e

Unobstructed surface area in m

2

(1 m

2

= 10.9 ft

2

)

T

ext

Maximum expected temperature in

o

C outside the

enclosure

T

int

Maximum permissible temperature in

o

C inside the

enclosure

P Power in Watts dissipated by all heat sources in the

enclosure

k Heat transmission coefficient of the enclosure material

in W/m

2

/

o

C

Example

To calculate the size of an enclosure for the following:

• Two drives operating at the Normal Duty rating

• External EMC filter for each drive

• Braking resistors are to be mounted outside the enclosure

• Maximum ambient temperature inside the enclosure: 40°C

• Maximum ambient temperature outside the enclosure: 30°C

For example, if the power dissipation from each drive is 187 W and the

power dissipation from each external EMC filter is 9.2 W.

Total dissipation: 2 x (187 + 9.2) =392.4 W

Power dissipation for the drives and the external EMC filters can be

obtained from Chapter 12 Technical data on page 227

The enclosure is to be made from painted 2 mm (0.079 in) sheet steel

having a heat transmission coefficient of 5.5 W/m

2

/

o

C. Only the top,

front, and two sides of the enclosure are free to dissipate heat.

The value of 5.5 W/m

2

/ºC can generally be used with a sheet steel

enclosure (exact values can be obtained by the supplier of the material).

If in any doubt, allow for a greater margin in the temperature rise.

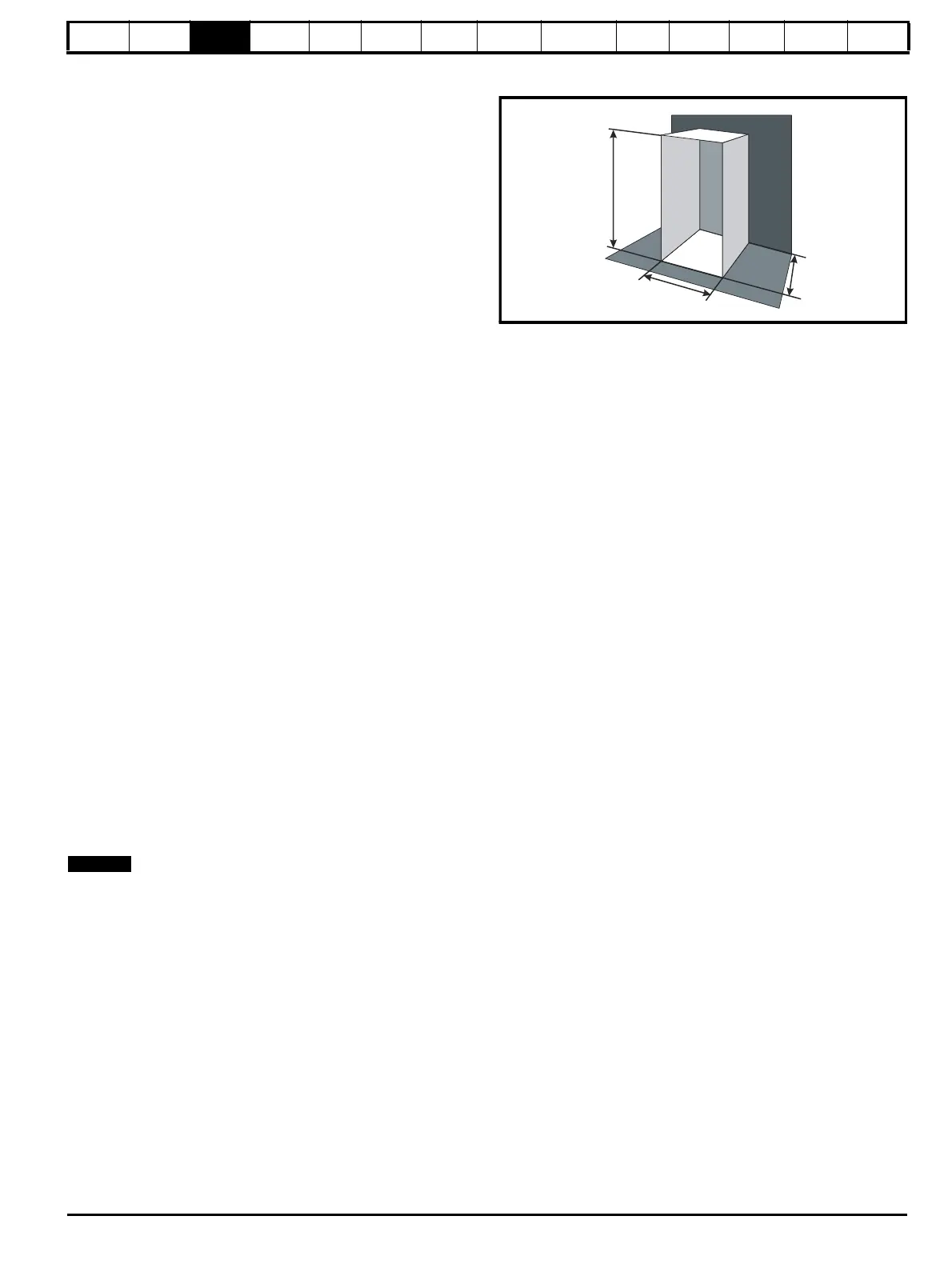

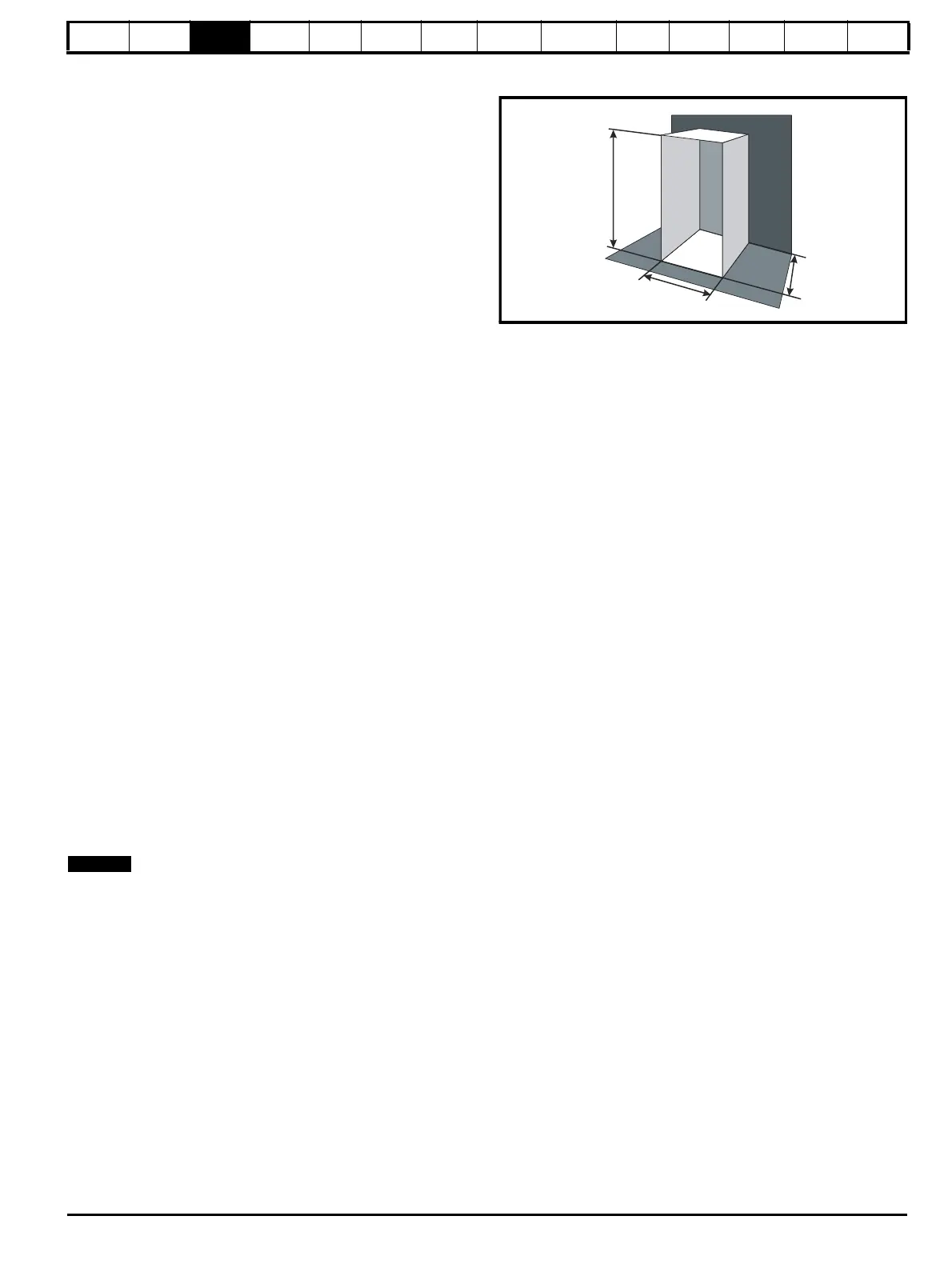

Figure 3-29 Enclosure having front, sides and top panels free to

dissipate heat

Insert the following values:

T

int

40 °C

T

ext

30 °C

k 5.5

P 392.4 W

The minimum required heat conducting area is then:

= 7.135 m

2

(77.8 ft

2

) (1 m

2

= 10.9 ft

2

)

Estimate two of the enclosure dimensions - the height (H) and depth (D),

for instance. Calculate the width (W) from:

Inserting H = 2m and D = 0.6 m, obtain the minimum width:

=1.821 m (71.7 in)

If the enclosure is too large for the space available, it can be made

smaller only by attending to one or all of the following:

• Using a lower PWM switching frequency to reduce the dissipation in

the drives

• Reducing the ambient temperature outside the enclosure, and/or

applying forced-air cooling to the outside of the enclosure

• Reducing the number of drives in the enclosure

• Removing other heat-generating equipment

Calculating the air-flow in a ventilated enclosure

The dimensions of the enclosure are required only for accommodating

the equipment. The equipment is cooled by the forced air flow.

Calculate the minimum required volume of ventilating air from:

Where:

V Air-flow in m

3

per hour (1 m

3

/hr = 0.59 ft

3

/min)

T

ext

Maximum expected temperature in

°C outside the

enclosure

T

int

Maximum permissible temperature in °C inside the

enclosure

P Power in Watts dissipated by all heat sources in the

enclosure

k Ratio of

Where:

P

0

is the air pressure at sea level

P

I

is the air pressure at the installation

Typically use a factor of 1.2 to 1.3, to allow also for pressure-drops in

dirty air-filters.

A

e

P

kT

int

T

ext

–()

-----------------------------------

=

A

e

392.4

5.5 40 30–()

---------------------------------

=

W

A

e

2HD–

HD+

--------------------------

=

W

7.135 2 2× 0.6×()–

20.6+

-----------------------------------------------------

=

V

3kP

T

int

T

ext

–

---------------------------

=

Loading...

Loading...