Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running

the motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL listing

information

114 Unidrive M702 User Guide

Issue Number: 3

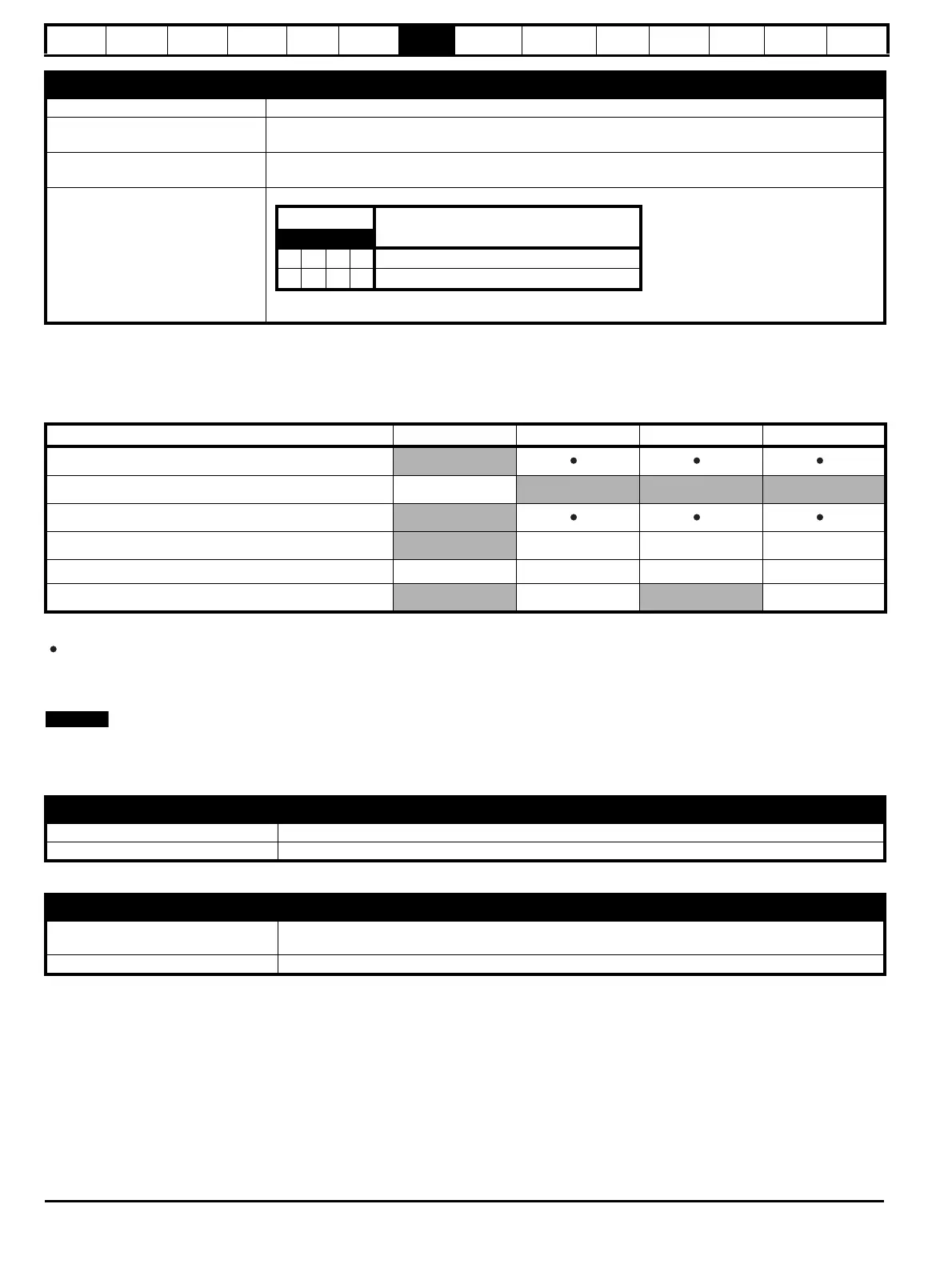

7.4.3 P2 position interface

This section shows the parameter settings which must be made to use each of the compatible feedback device types with the P2 position interface on

the drive. For more information on the parameters listed here please refer to the Parameter Reference Guide. If the position feedback device

connected to the P2 position interface is required to be used for motor control feedback then Pr 03.026 will need to be set to P2 Drive (1).

Table 7-4 Parameters required for feedback device set-up on the P2 position interface

Information required to be entered by the user.

Parameter can be set-up automatically by the drive through auto-configuration. Parameter must be set by the user if auto-configuration is

disabled (i.e. Pr 03.041 = Disabled (0)).

The P2 position interface does not have its own independent power supply output. Therefore, any position feedback device connected to the P2

position interface must either share the P1 power supply output on pin 13 of the 15-way D-type, or be supplied from an external source.

The termination resistors are always enabled on the P2 position interface. Wire break detection is not available when using AB, FD or FR position

feedback device types on the P2 position interface.

Table 7-4 shows a summary of the parameters required to set-up each feedback device. More detailed information follows.

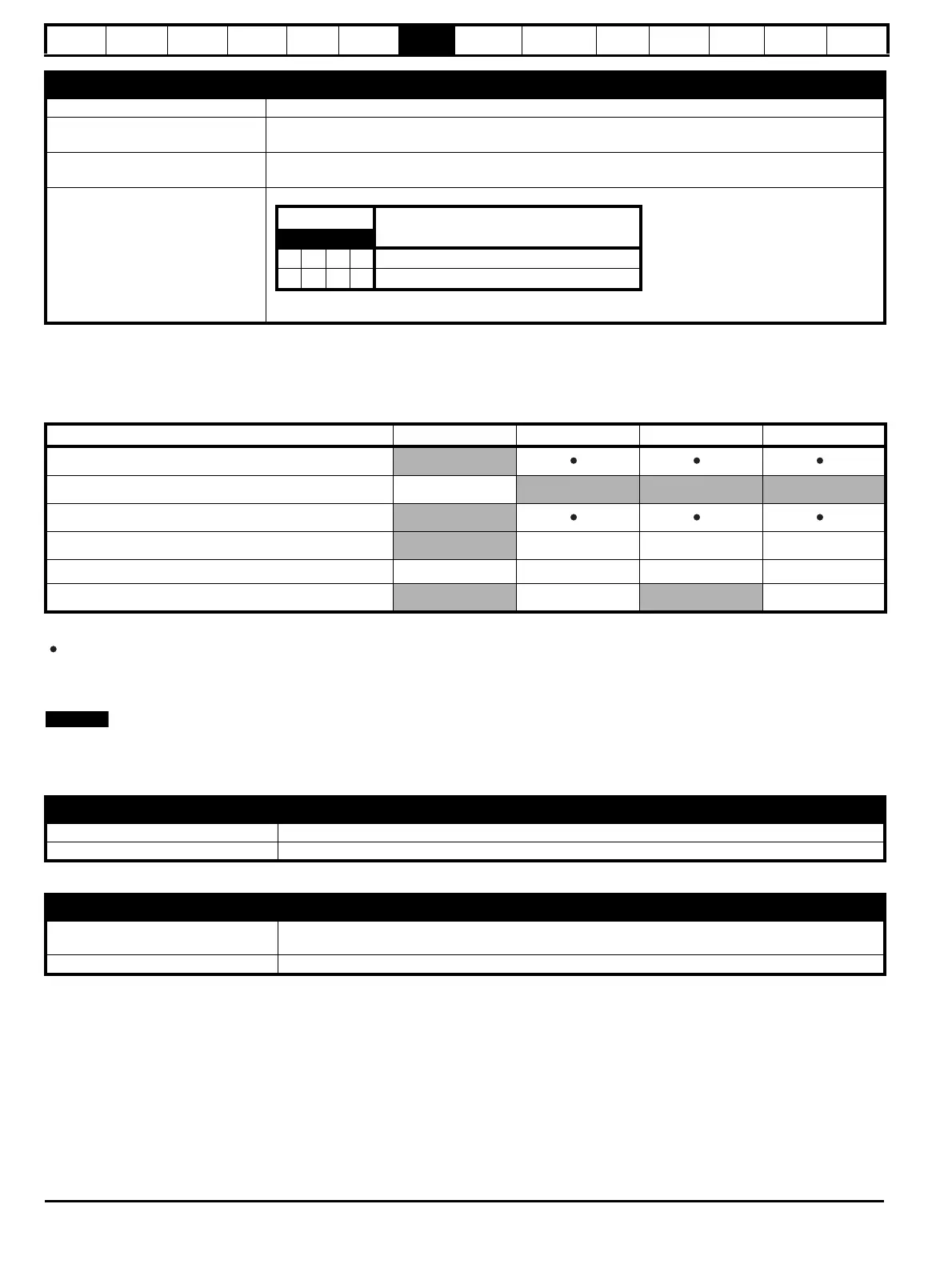

Resolver

Device Type (03.038) Resolver (14)

Resolver Poles (03.065)

Set number of Resolver poles

2 poles, 4 poles, 6 poles, 8 poles

Resolver Excitation (03.066)

Set Resolver excitation voltage and frequency

6 V Auto (0), 4 V Auto (1), 6 V 6 kHz (2), 4 V 6 kHz (3), 6 V 8 kHz (4), 4 V 8 kHz (5)

Error Detection Level (03.040)

So for example, to enable the wire break error detection, set Pr 03.040 to 0001.

Bit

Description

3 2 1 0

xxx1

Enable wire break detection

1xxx

Disable trips Encoder 1 to Encoder 7

Parameter AB, FD, FR EnDat SSI BiSS

P2 Rotary Turns Bits (03.133)

P2 Rotary Lines Per Revolution (03.134)

P2 Comms Bits (03.135)

P2 Comms Baud Rate (03.137)

P2 Device Type (03.138)

P2 Auto–configuration Select (03.141)

Standard quadrature encoder (A, B, Z)

Device Type (03.138) AB (1) for a quadrature encoder

Rotary Line Per Revolution (03.134) Set to the number of lines per revolution of the encoder

Incremental encoder with Frequency and Direction (F and D), or Forward and Reverse (CW and CCW) signals

Device Type (03.138)

FD (2) for frequency and direction signals without commutation signals

FR (3) for forward and reverse signals without commutation signals

Rotary Line Per Revolution (03.134) Set to the number of pulses per revolution of the encoder divided by 2

Loading...

Loading...