Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running

the motor

Optimization

NV Media Card

Operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL listing

information

Unidrive M702 User Guide 43

Issue Number: 3

When designing an IP65 (NEMA 12) enclosure (Figure 3-30 Example of

IP65 (NEMA 12) through-panel layout on page 40), consideration should

be made to the dissipation from the front of the drive.

Table 3-6 Power losses from the front of the drive when through-

panel mounted

3.10 Heatsink mounted brake resistor

3.10.1 Size 3, 4 and 5 internal braking resistor

Size 3, 4 and 5 have been designed with an optional space-saving

heatsink mounted resistor. The resistor can be installed within the

heatsink fins of the drive. When the heatsink resistor is used, an external

thermal protection device is not required as the resistor is designed such

that it will fail safely under any fault conditions. The in-built software

overload protection is set-up at default to protect the resistor. The

resistor is rated to IP54 (NEMA 12).

3.10.2 Internal braking resistor installation

instructions

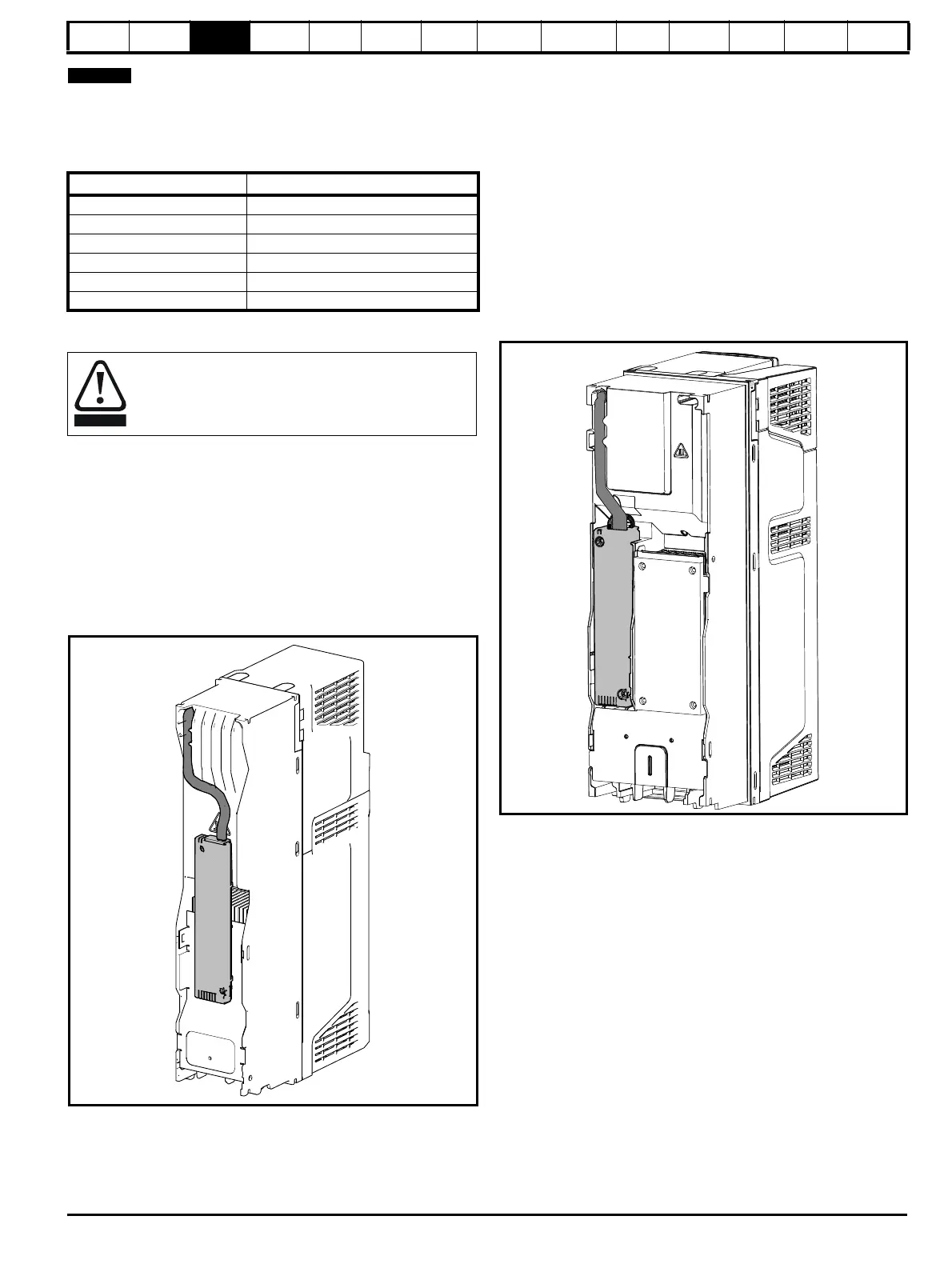

Figure 3-36 Brake resistor installation on size 3

1. Remove the terminal covers as detailed in section 3.3.1 Removing

the terminal covers on page 22.

2. Remove the internal EMC filter as shown in section 4.12.2 Internal

EMC filter on page 70.

3. Remove the brake resistor bung from the hole in the chassis, the

closed end of the bung will need to be pierced so that the cable has

access to be routed through.

4. Feed brake resistor bung onto outer insulation of brake resistor

cable. The wider end of the bung should be inserted first. The

Narrow end should align with end of insulation.

5. Install the braking resistor to the heatsink using captive screws. The

screws should be tighten to a maximum torque of 2 N m (1.5 lb ft).

6. Route the cables through the provided hole at the rear of the

heatsink as shown in Figure 3-36 and take the cable out from the

front side of the drive. Ensure the cables are routed between the fins

of the heatsink.

7. Crimp the cable ends and make appropriate connections. The brake

terminals must be tightened to a maximum torque of 2 N m (1.5 Ib ft).

8. Replace the terminal covers on the drive, tighten to a maximum

torque of 1 N m (0.7 lb ft).

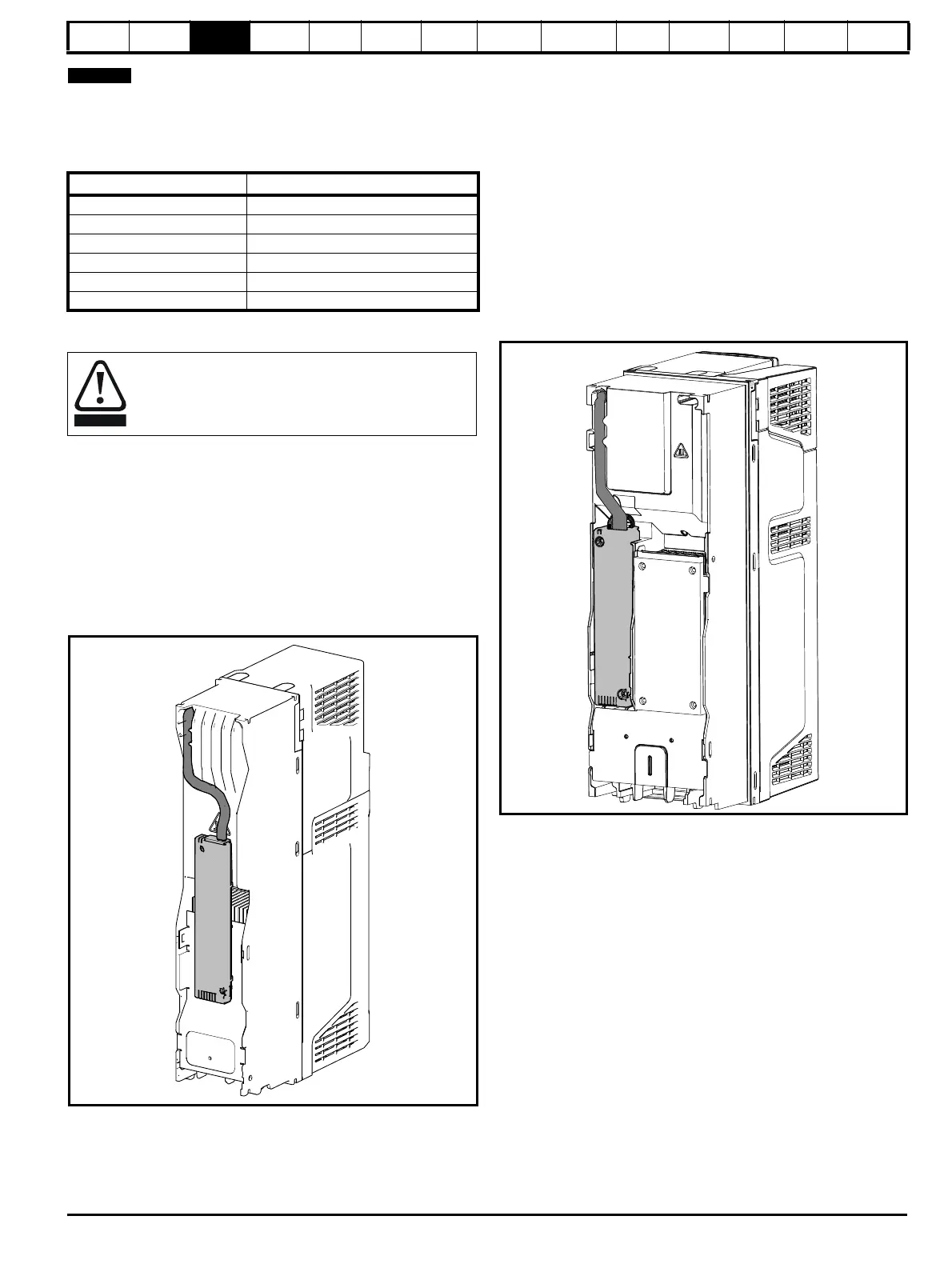

Figure 3-37 Brake resistor installation on size 4

1. Remove the terminal covers as detailed in section 3.3.1 Removing

the terminal covers on page 22.

2. Remove the brake resistor bung from the hole in the chassis, the

closed end of the bung will need to be pierced so that the cable has

access to be routed through.

3. Feed brake resistor bung onto outer insulation of brake resistor

cable. The wider end of the bung should be inserted first. The

Narrow end should align with end of insulation.

4. Install the braking resistor to the heatsink using captive screws as

shown in Figure 3-37. The screws should be tighten to a maximum

torque of 2 N m (1.5 lb ft).

5. Route the cables through the provided hole at the rear of the

heatsink as shown in Figure 3-37 and take the cable out from the

front side of the drive. Ensure the cables are routed between the

tabs of the heatsink, and the cables are not trapped between the

heatsink fins and the resistor.

6. Crimp the cable ends and make appropriate connections. The brake

terminals must be tightened to a maximum torque of 2 N m (1.5 Ib

ft).

7. Replace the terminal covers on the drive, tighten to a maximum

torque of 1 N m (0.7 lb ft).

Frame size Power loss

3

4

5

6

7

8

The internal / heatsink mounted braking resistors must only

be used with the following drives.

Brake resistor 1220-2752-00 must only be used with size 3

drives. Brake resistor 1299-0003-00 must only be used with

size 4 and 5 drives.

Loading...

Loading...