9 Preparation for Wiring and Power Supply Wiring

9.2 Cable Connecting Procedures

109

FX3G Series Programmable Controllers

User's Manual - Hardware Edition

1

Introduction

2

Features and

Part Names

3

Product

Introduction

4

Specifications

5

Version and

Peripheral

Devices

6

System

Configuration

7

Input/Output

Nos., Unit Nos.

8

Installation

9

Preparation and

Power Supply

Wiring

10

Input Wiring

9.2.3 Terminal block (for europe) [expansion board and special adapters]

The expansion board and special adapters of a terminal block type have terminal blocks for Europe.

1. Applicable products

2. Electric wires

Compliant electric wires and tightening torque

3. Treatment of electric wire ends

Treat the ends of stranded wires and solid wires without coating or using bar terminals with insulating sleeve.

• Treatment of stranded wires and solid wires without coating

- Twist the ends of stranded wires tightly so that loose wires will not

stick out.

- Do not solder-plate the electric wire ends.

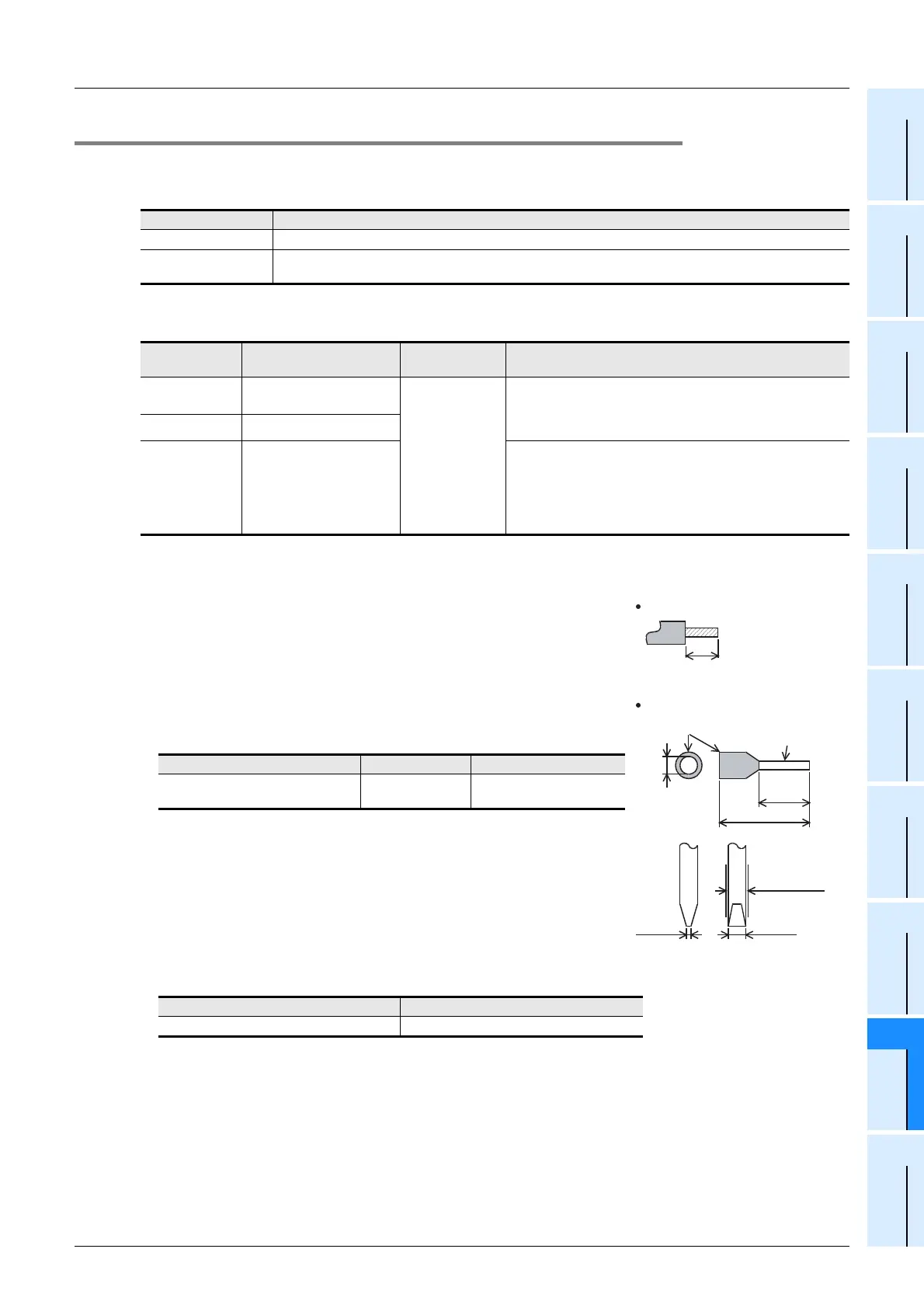

• Treatment using bar terminal with insulating sleeve

It may be difficult to insert the electric wire into the insulating sleeve

depending on the thickness of the electric wire sheath. Select the

electric wire referring to the outline drawing.

4. Tool

• For tightening the terminal, use a commercially available small

screwdriver having a straight form that is not widened toward the end as

shown right.

Caution :

If the diameter of screwdriver grip is too small, tightening torque will not be

able to be achieved. Use the following recommended screwdriver or an

appropriate replacement (grip diameter: approximately 25mm (0.98") ).

Classification Model names

Expansion Board FX3G-485-BD, FX3G-2AD-BD, FX3G-1DA-BD

Special Adapters

FX3U-485ADP(-MB), FX3U-4AD-ADP, FX3U-4DA-ADP, FX3U-4AD-PT-ADP, FX3U-4AD-PTW-ADP,

FX3U-4AD-PNK-ADP, FX3U-4AD-TC-ADP

Electric wire size

(stranded wire/solid wire)

Tightening

torque

End treatment

One electric wire

0.3mm

2

to 0.5mm

2

(AWG22 to 20)

0.22 to 0.25N•m

• Remove the coating of the stranded wire, twist the core wires,

and connect the wires directly.

• Remove the coating from the solid wire, and connect the wire

directly.

Two electric wires

0.3mm

2

(AWG22)

Bar terminal with

insulating sleeve

0.3 mm

2

to 0.5 mm

2

(AWG22 to 20)

(Refer to the following outline

drawing of bar terminal.)

• Bar terminal with insulating sleeve

(recommended product)

AI 0.5-8WH : Phoenix Contact

• Caulking tool

CRIMPFOX ZA 3 : Phoenix Contact

(CRIMPFOX UD 6 : Phoenix Contact)

Manufacturer Model names Caulking tool

Phoenix Contact AI 0.5-8WH

CRIMPFOX ZA 3

(CRIMPFOX UD 6)

Manufacturer Model names

Phoenix Contact SZS 0.4 x 2.5

9mm

(0.36")

Stranded wire/solid wire

8mm

(0.32")

Contact area

(Crimp area)

14mm(0.56")

2.6mm

(0.11")

Insulating sleeve

Bar terminal with insulating sleeve

0.4mm

(0.02")

2.5mm

(0.1")

With

straight tip

Loading...

Loading...