Programming and Operating Manual (Milling)

204 6FC5398-4DP10-0BA6, 09/2017

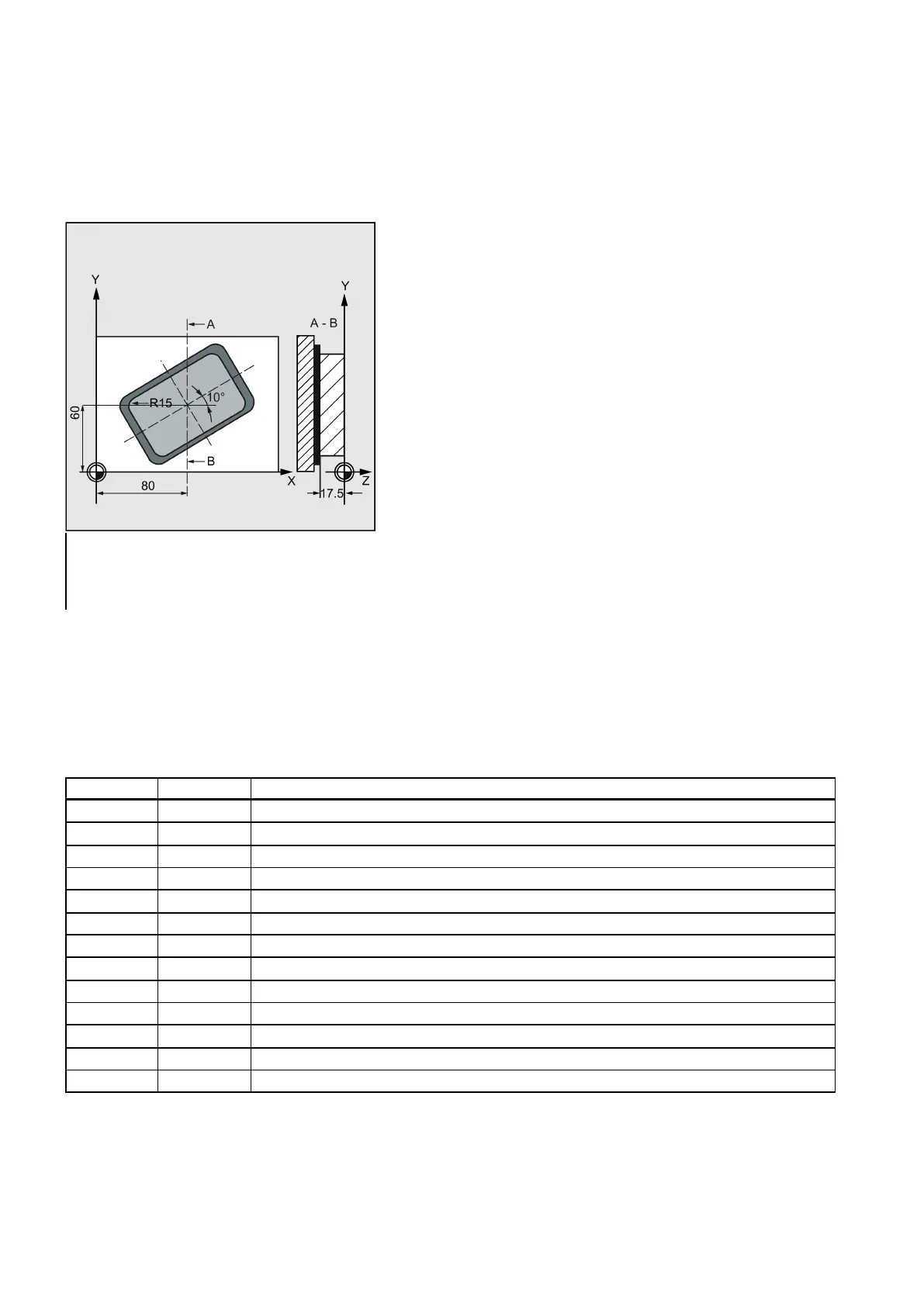

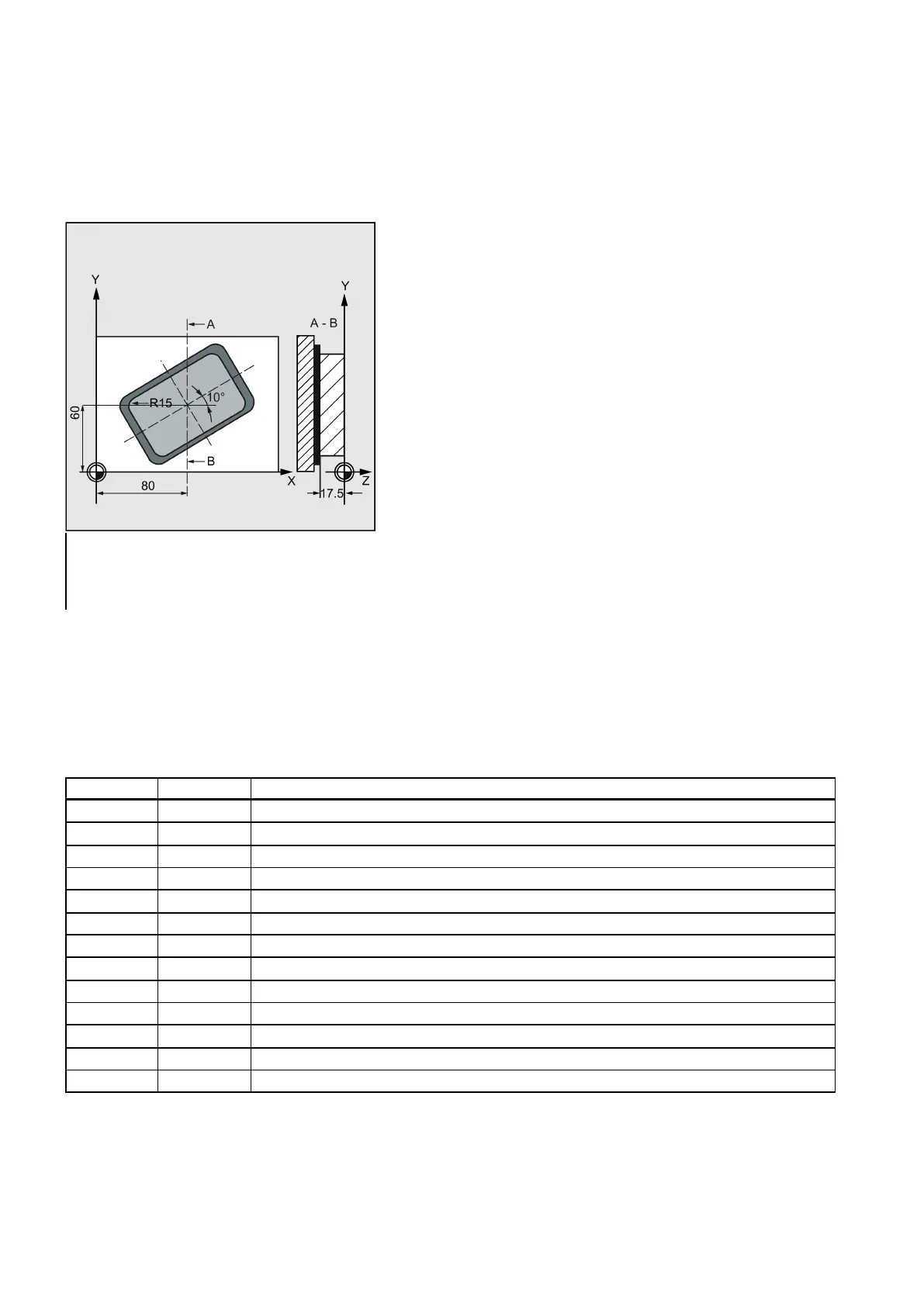

Programming example: Spigot

Use this program to machine in the XY plane a spigot that is 60 mm long, 40 mm wide and has 15 mm corner radius. The

spigot has an angle of 10 degrees relative to the X axis and is premanufactured with a length allowance of 80 mm and a

width allowance of 50 mm.

See the following programming example for rectangular spigot:

N10 G90 G0 G17 X100 Y100 T20 D1 S3000 M3

; Specification of technology values

N30 CYCLE76 (10, 0, 2, -17.5, , 60, 40, 15, 80, 60, 10, 11,

, , 900, 800, 0, 1, 80, 50)

Milling a circular spigot - CYCLE77

Programming

CYCLE77 (RTP, RFP, SDIS, DP, DPR, PRAD, PA, PO, MID, FAL, FALD, FFP1, FFD, CDIR, VARI, AP1)

The following input parameters are always required:

Retraction plane (absolute)

RFP REAL Reference plane (absolute)

SDIS REAL Safety clearance (enter without sign)

DPR REAL Depth relative to the reference plane (enter without sign)

Spigot diameter (enter without sign)

Reference point, first axis of plane

Reference point, second axis of plane

MID REAL Maximum depth infeed (incremental; enter without sign)

Final machining allowance at the margin contour (incremental)

FALD REAL Finishing allowance at the base (incremental, enter without sign)

Feedrate for surface machining

Feedrate for depth infeed (or spatial infeed)

Loading...

Loading...