Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA6, 09/2017

49

Entering the tool wear offsets

You must distinguish the direction of tool wear compensation clearly.

Two methods are available for entering the tool wear offsets: absolute input and incremental input (default: absolute input).

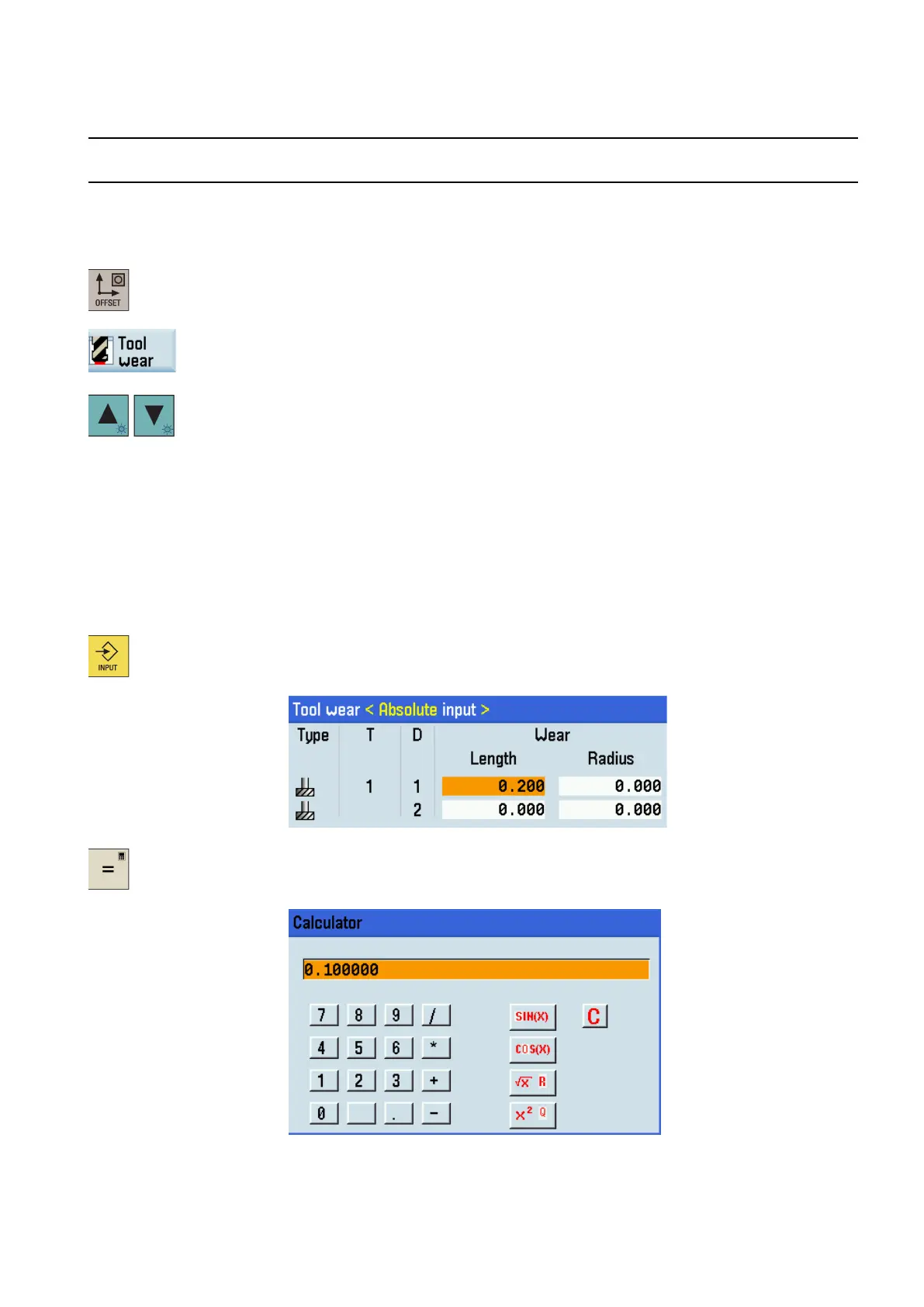

Operating sequence for absolute input

1.

Select the offset operating area.

2.

Open the tool wear window.

3.

Use the cursor keys to select the required tools and their edges.

4.

Enter the desired tool length wear parameter and the tool radius wear parameter (range of

value in mm:

-9.999 to 9.999).

Positive value: the tool compensates in a direction of moving away from the wor

kpiece.

Negative value: the tool compensates in a direction of approaching the workpiece.

If there is already a non

-zero offset value in the input field (for example, the existing tool

length offset value is "0.1") and you desire to increase the offset value, then you can either

directly enter the sum of the existing offset value and the increment, or call the pocket calcu-

lator to work out the tool wear

offset (proceed through Steps 6 to 9).

5.

s key or move the cursor to activate the compensation.

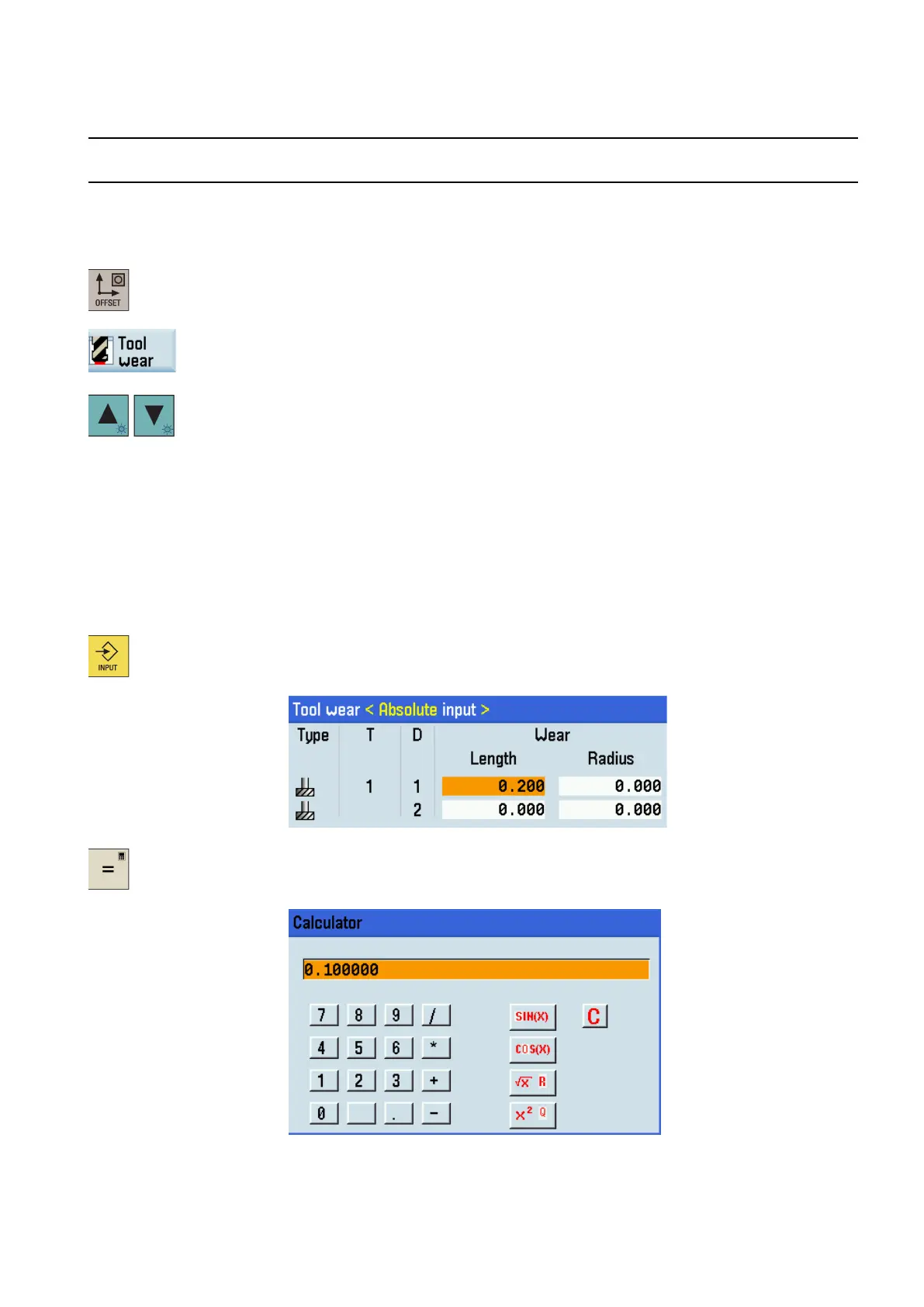

6.

If you desire to use the pocket calculator,

position the cursor on the desired input field and

press this key. Then the pocket calculator is opened:

Loading...

Loading...