Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA6, 09/2017

211

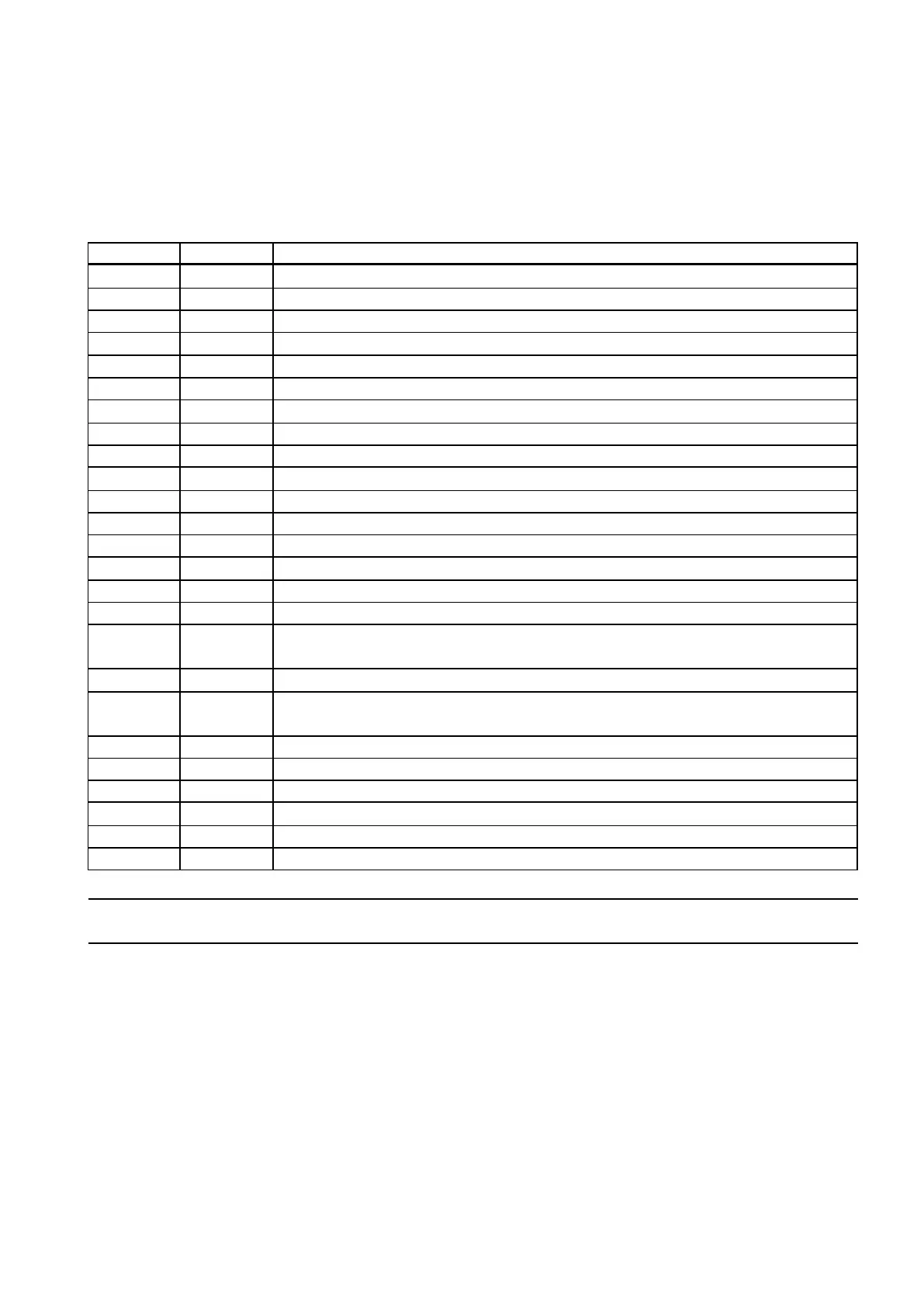

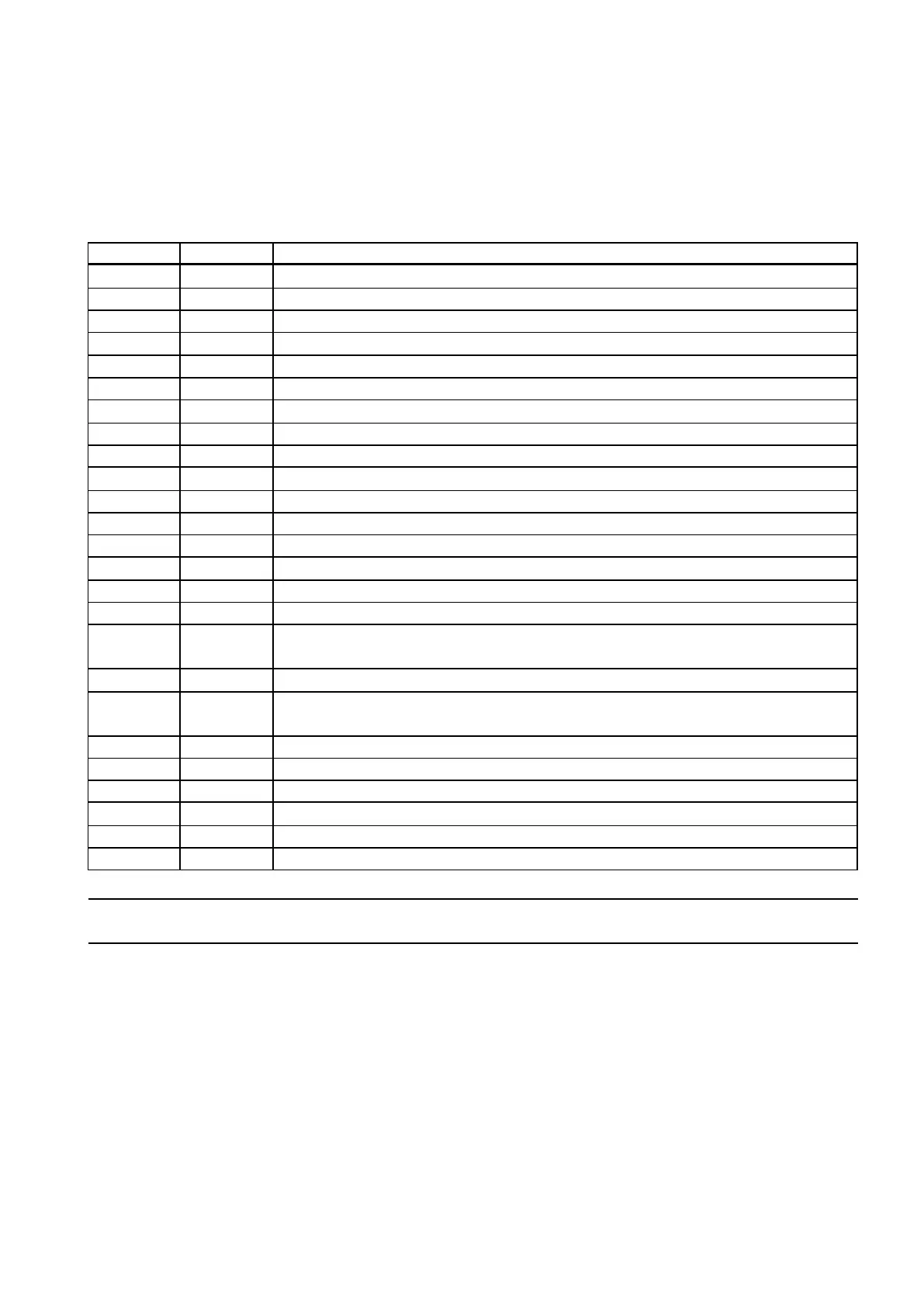

Slots on a circle - SLOT1

Programming

SLOT1 (RTP, RFP, SDIS, DP, DPR, NUM, LENG, WID, CPA, CPO, RAD, STA1, INDA, FFD, FFP1, MID, CDIR, FAL, VARI,

MIDF, FFP2, SSF, FALD, STA2, DP1)

Retraction plane (absolute)

Reference plane (absolute)

Safety clearance (enter without sign)

DP REAL Slot depth (absolute)

DPR REAL Slot depth relative to the reference plane (enter without sign)

LENG REAL Slot length (enter without sign)

Slot width (enter without sign)

Center point of circle (absolute), first axis of the plane

CPO REAL Center point of circle (absolute), second axis of the plane

RAD REAL Radius of the circle (enter without sign)

STA1 REAL Starting angle

FFD REAL Feedrate for depth infeed

FFP1 REAL Feedrate for surface machining

Maximum infeed depth for one infeed (enter without sign)

CDIR INT Milling direction for machining the slot

Values: 2 (for G2), 3 (for G3)

FAL REAL Finishing allowance at the slot edge (enter without sign)

VARI INT Machining type

Values: 0 = complete machining, 1 = roughing, 2 = finishing

MIDF REAL Maximum infeed depth for finishing

FALD REAL Finishing allowance at the slot base (enter without sign)

STA2 REAL Maximum insertion angle for oscillation movement

DP1 REAL Insertion depth per revolution for helix (incremental)

The cycle requires a milling cutter with an "end tooth cutting across center" (DIN844).

Loading...

Loading...