Programming and Operating Manual (Milling)

16 6FC5398-4DP10-0BA6, 09/2017

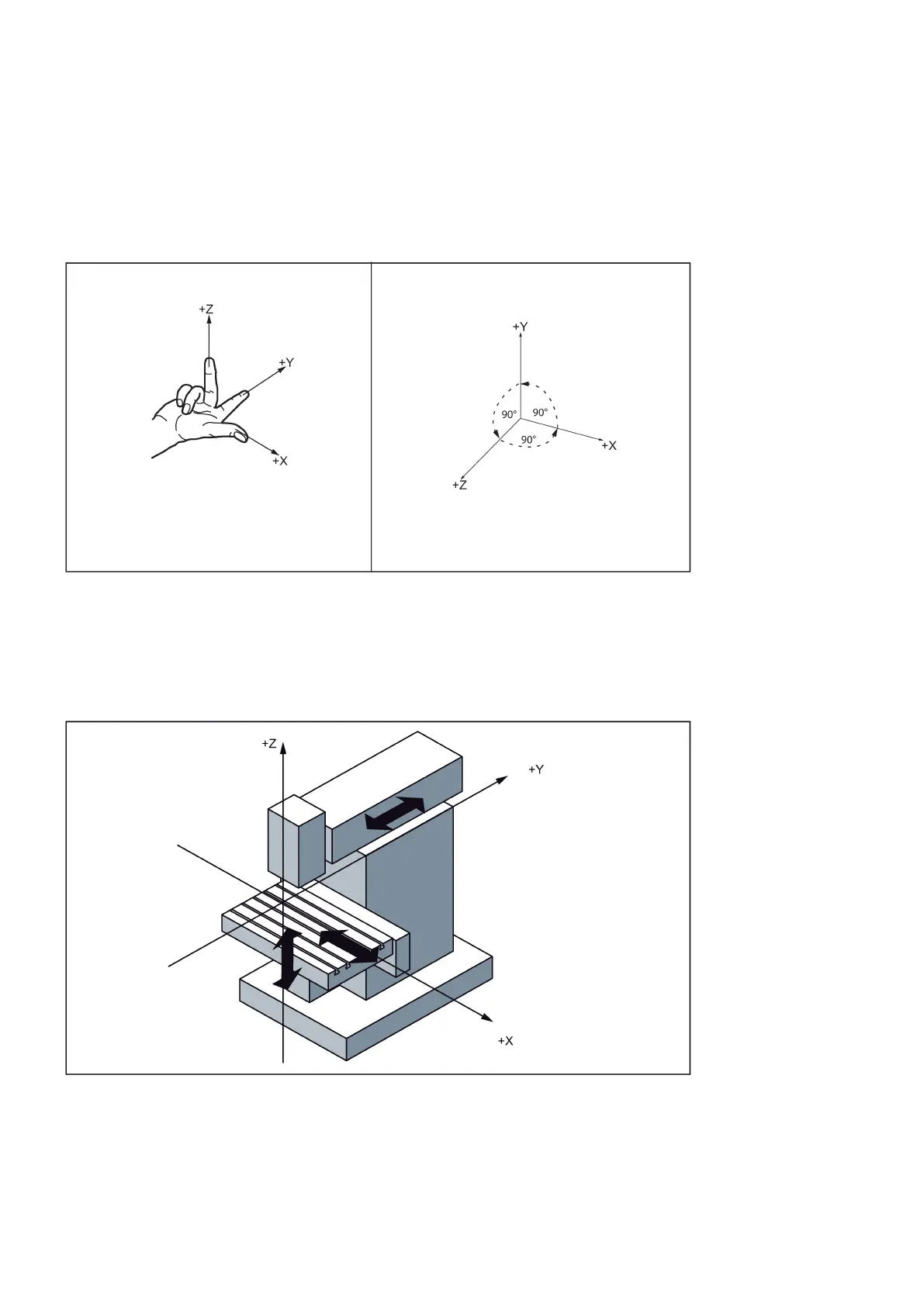

As a rule, a coordinate system is formed from three mutually perpendicular coordinate axes. The positive directions of the

coordinate axes are defined using the Cartesian coordinate system. The coordinate system is related to the workpiece and

programming takes place independently of whether the tool or the workpiece is being traversed. When programming, it is

always assumed that the tool traverses relative to the coordinate system of the workpiece, which is intended to be

stationary.

The figure below illustrates how to determine the axis directions.

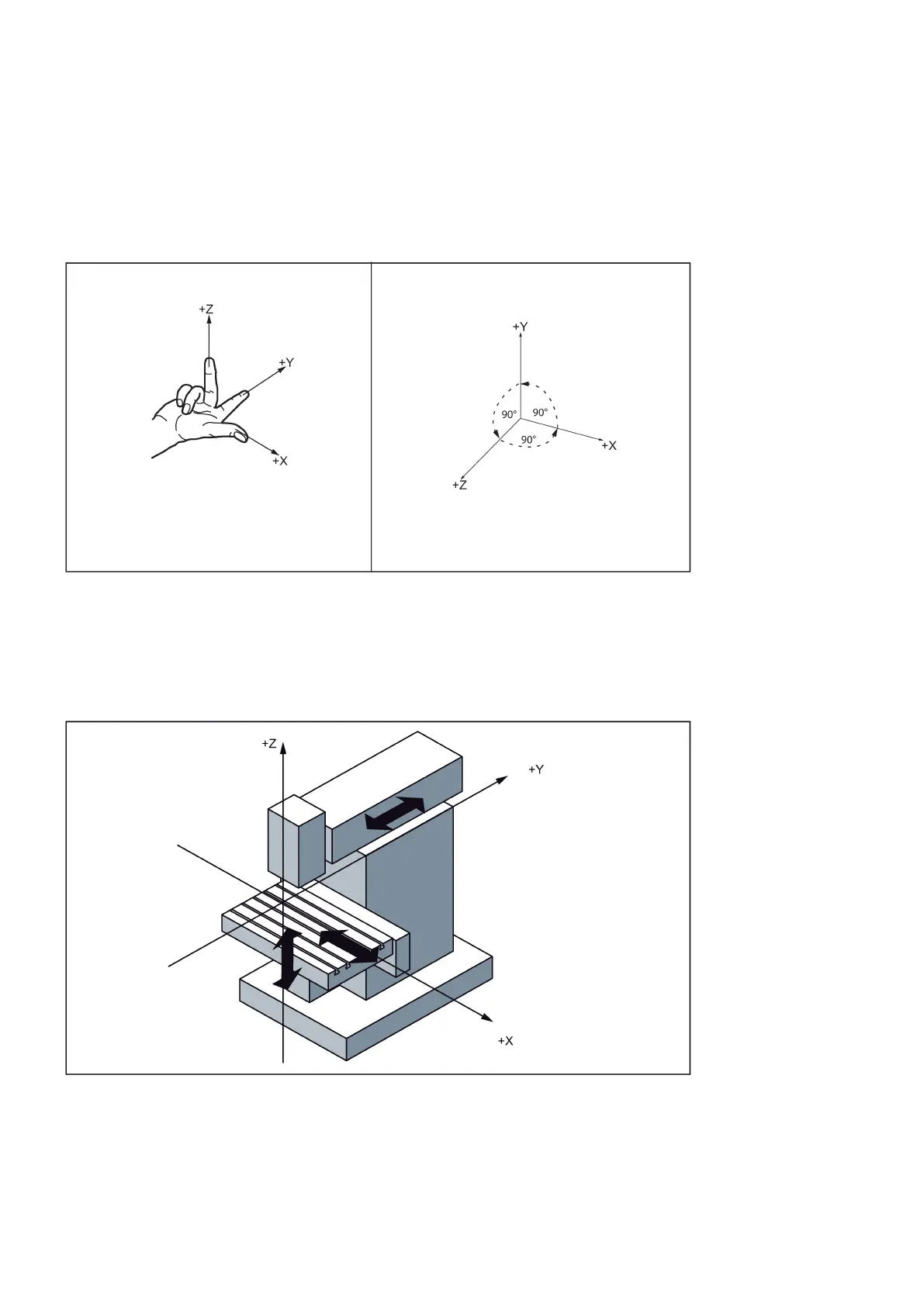

Machine coordinate system (MCS)

The orientation of the coordinate system relative to the machine depends on the respective machine types. It can be rotated

in different positions.

The directions of the axes follow the Cartesian coordinate system.

The figure below shows an example of the machine coordinate system of a flat-body turning machine with a front tool holder.

The origin of this coordinate system is the

,

defined by the machine manufacturer.

The traversing range of the

can be in the negative range.

Loading...

Loading...