Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA6, 09/2017

207

A tool compensation must be programmed before the cycle is called. Otherwise, the cycle is canceled and alarm 61009

"Active tool number=0" is output. Internall

y in the cycle, a new current workpiece coordinate system is used which influences

the actual value display. The zero point of this coordinate system is to be found in the pocket center point.

At the end of the cycle, the original coordinate system is active again.

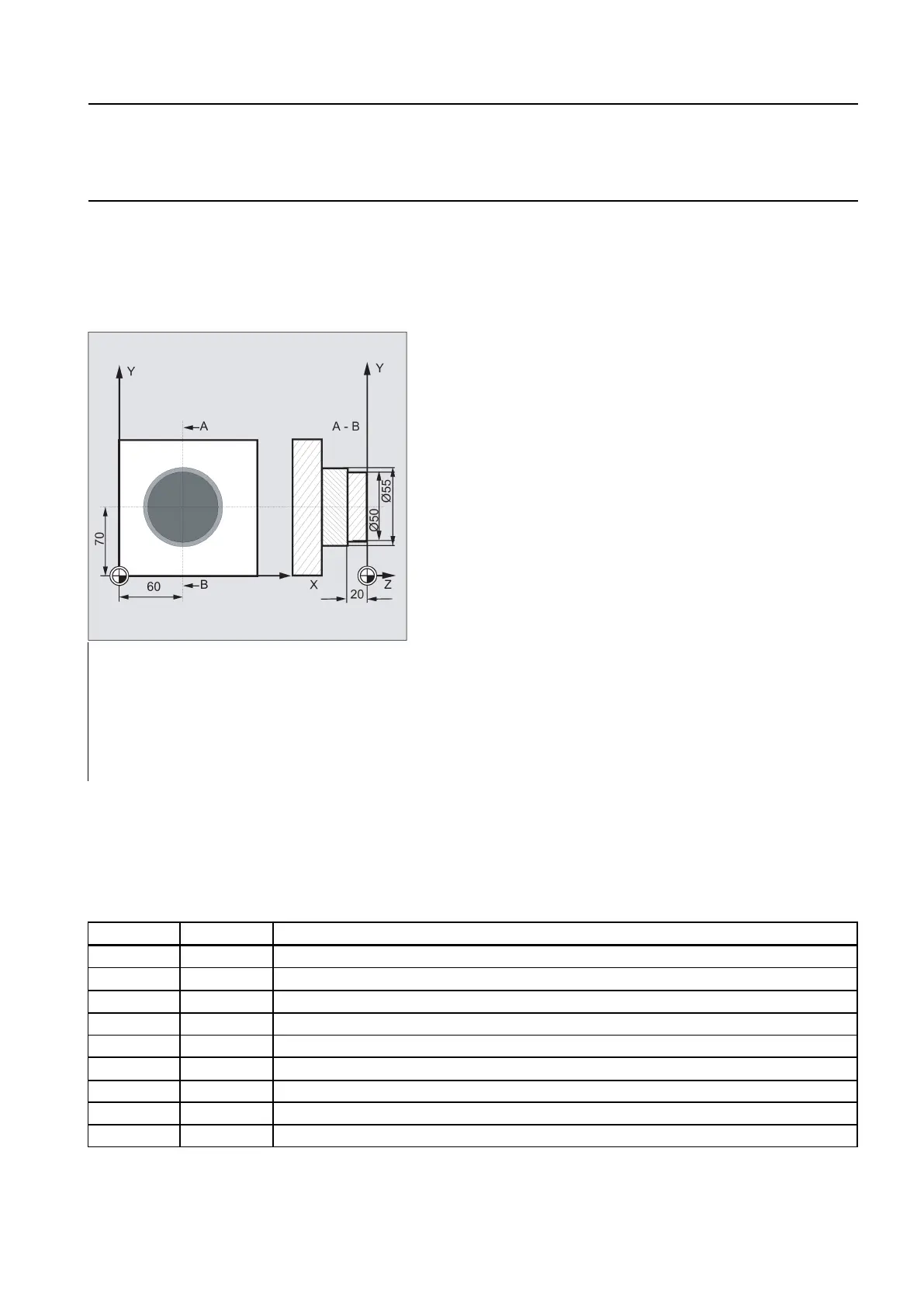

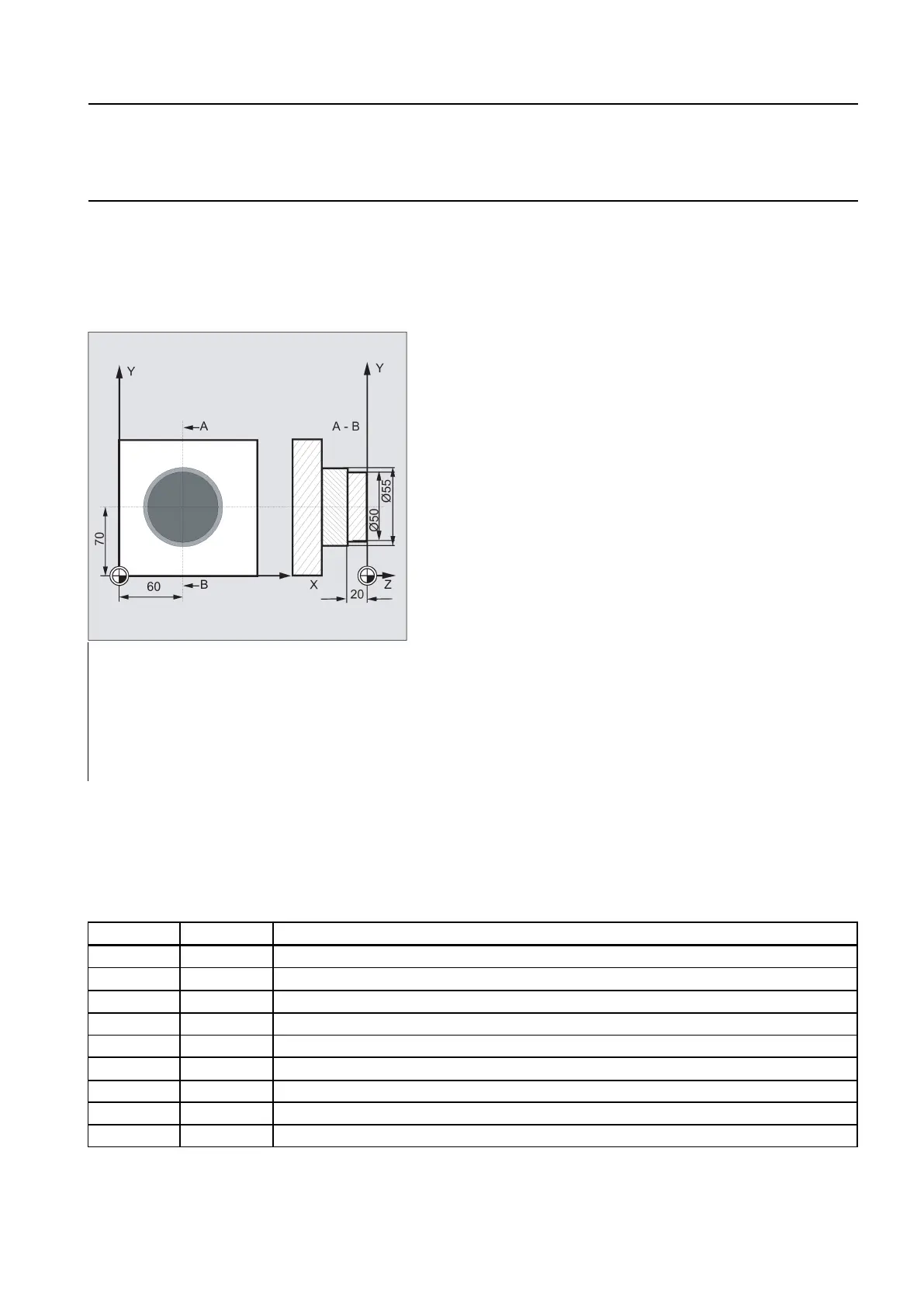

Programming example: Circular spigot

Machining a spigot from a blank with a diameter of 55 mm and a maximum infeed of 10 mm per cut; specification of a final

machining allowance for subsequent finishing of the spigot surface. The whole machining is performed with reverse rotation.

See the following programming example for circular spigot:

N10 G90 G17 G0 S1800 M3 D1 T1

; Specification of technology values

N20 CYCLE77 (10, 0, 3, -20, ,50, 60, 70, 10, 0.5, 0, 900,

800, 1, 1, 55 )

; Specification of technology values

N50 CYCLE77 (10, 0, 3, -20, , 50, 60, 70, 10, 0, 0, 800 ,

800, 1, 2, 55 )

Long holes located on a circle - LONGHOLE

Programming

LONGHOLE (RTP, RFP, SDIS, DP, DPR, NUM, LENG, CPA, CPO, RAD, STA1, INDA, FFD, FFP1, MID)

RTP REAL Retraction plane (absolute)

Reference plane (absolute)

SDIS REAL Safety clearance (enter without sign)

Slot depth relative to the reference plane (enter without sign)

NUM INT Number of slots

Slot length (enter without sign)

Center point of circle (absolute), first axis of the plane

Center point of circle (absolute), second axis of the plane

Loading...

Loading...