Programming and Operating Manual (Milling)

6FC5398-4DP10-0BA6, 09/2017

327

The functions marked with an asterisk (*) are active at the start of the program in the CNC milling variant, unless otherwise

they are programmed or the machine manufacturer has preserved the default settings for the "milling" technology.

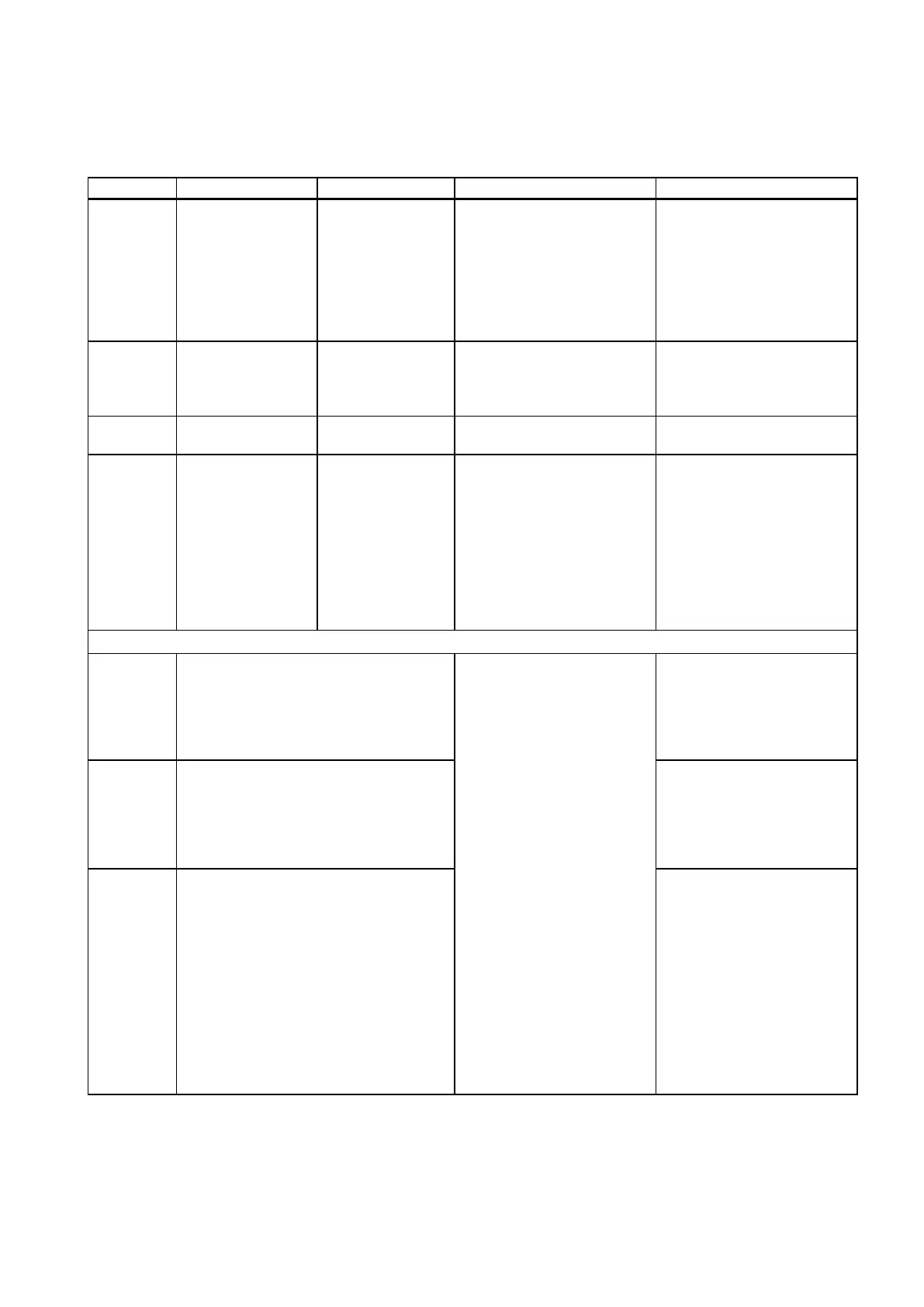

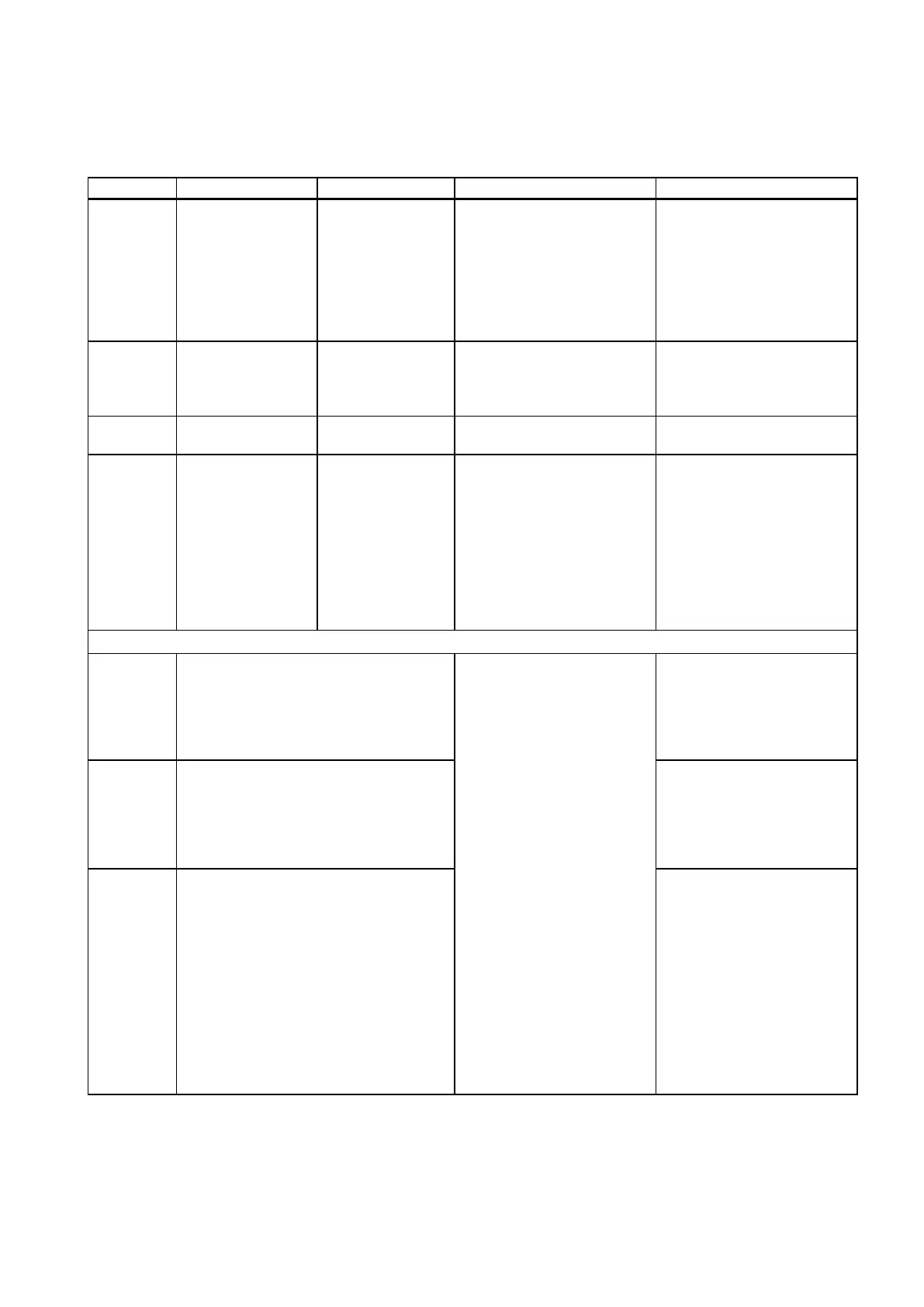

D Tool offset number

no sign

Contains compensation data

for a particular tool T... ; D0

indicates no compensation for

the tool, one tool activates 1~9

numbers, that is, one tool

carries at most nine different

compensation data at the

D...

F Feedrate 0.001 ... 99 999.999 Path velocity of a

tool/workpiece;

unit: mm/min or mm/revolution

depending on G94 or G95

F...

F Dwell time (in block

0.001 ... 99 999.999 Dwell time in seconds G4 F...; separate block

(preparatory func-

tion)

fied values

The G functions are divided

into G groups. Only one G

function from one group can

be written in one block.

A G function can either be

modal (until canceled by an-

other function from the same

group), or non-modal (only

effective for the block it is

or symbolic name, e.g.:

CIP

G0 Linear interpolation at rapid traverse rate 1: Motion commands (type of

interpolation), modally effec-

tive

G0 X... Y... Z... ; Cartesian in

polar coordinates:

G0 AP=... RP=...

or with additional axis:

G0 AP=... RP=... Z... ; e.g.:

G1 * Linear interpolation at feedrate G1 X... Y... Z... F...

in polar coordinates:

G1 AP=... RP=... F...

or with additional axis:

G1 AP=... RP=... Z... F... ;

e.g.: with G17 axis Z

G2

Circular interpolation in clockwise direction

(in conjunction with a third axis and

TURN=... also helix interpolation -> see

under TURN)

G2 X... Y... I... J... F... ; End

point and center point

G2 X... Y... CR=... F... ; Radi-

us and end point

G2 AR=... I... J... F... ; Aper-

ture angle and center point

G2 AR=... X... Y... F... ; Aper-

ture angle and end point in

polar coordinates:

G2 AP=... RP=... F...

or with additional axis:

G2 AP=... RP=... Z... F... ;

e.g.: with G17 axis Z

Loading...

Loading...