Programming and Operating Manual (Milling)

230 6FC5398-4DP10-0BA6, 09/2017

Thread milling - CYCLE90

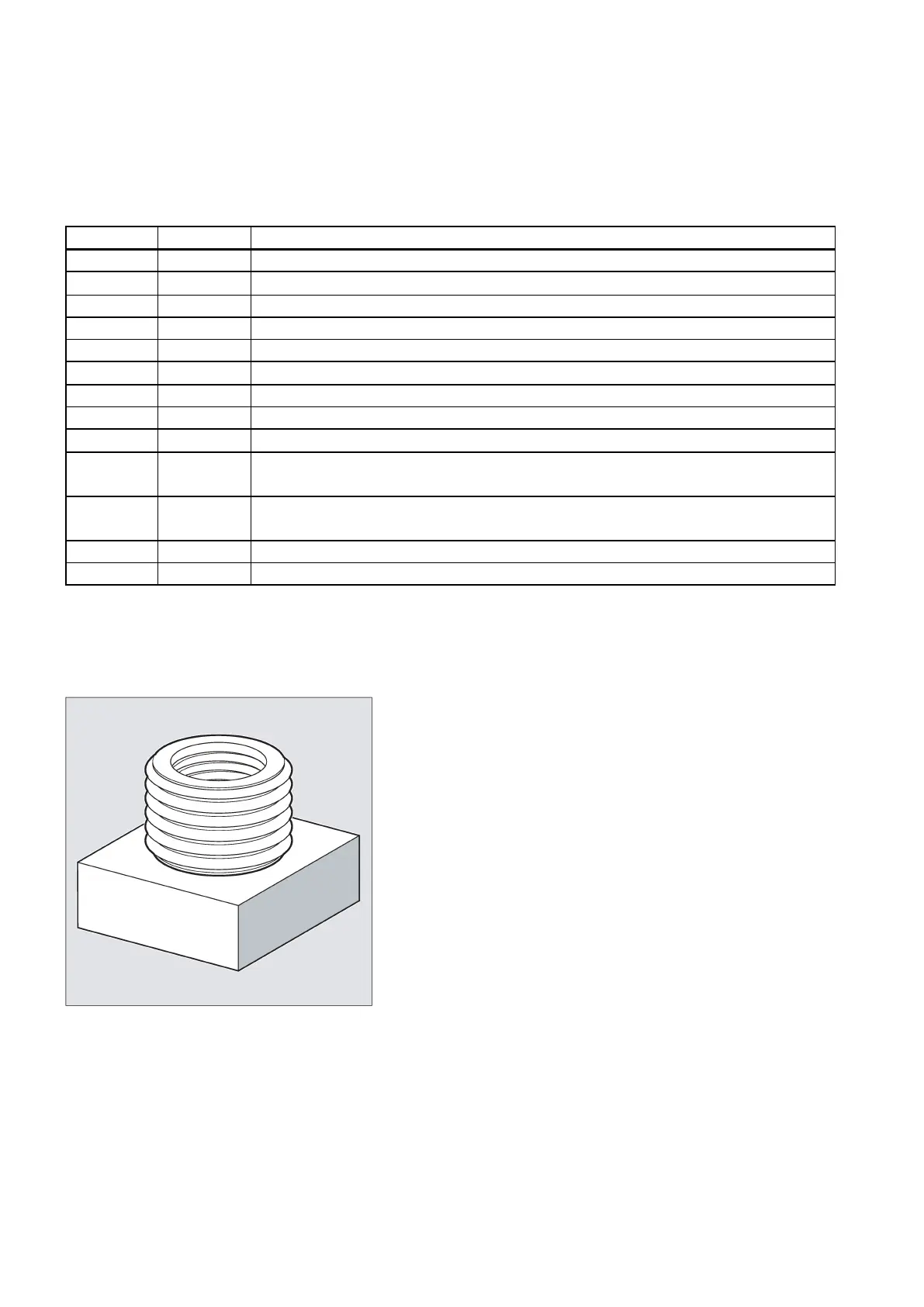

Programming

CYCLE90 (RTP, RFP, SDIS, DP, DPR, DIATH, KDIAM, PIT, FFR, CDIR, TYPTH, CPA, CPO)

Retraction plane (absolute)

RFP REAL Reference plane (absolute)

SDIS REAL Safety clearance (enter without sign)

DP REAL Final drilling depth (absolute)

Final drilling depth relative to the reference plane (enter without sign)

DIATH REAL Nominal diameter, outer diameter of the thread

KDIAM REAL Core diameter, internal diameter of the thread

Thread pitch; value range: 0.001 ... 2000.000 mm

FFR REAL Feedrate for thread milling (enter without sign)

CDIR INT Direction of rotation for thread milling

Values: 2 (for thread milling with G2), 3 (for thread milling with G3)

TYPTH INT Thread type

Values: 0=internal thread, 1=external thread

CPA REAL Center point of circle, abscissa (absolute)

Center point of circle, ordinate (absolute)

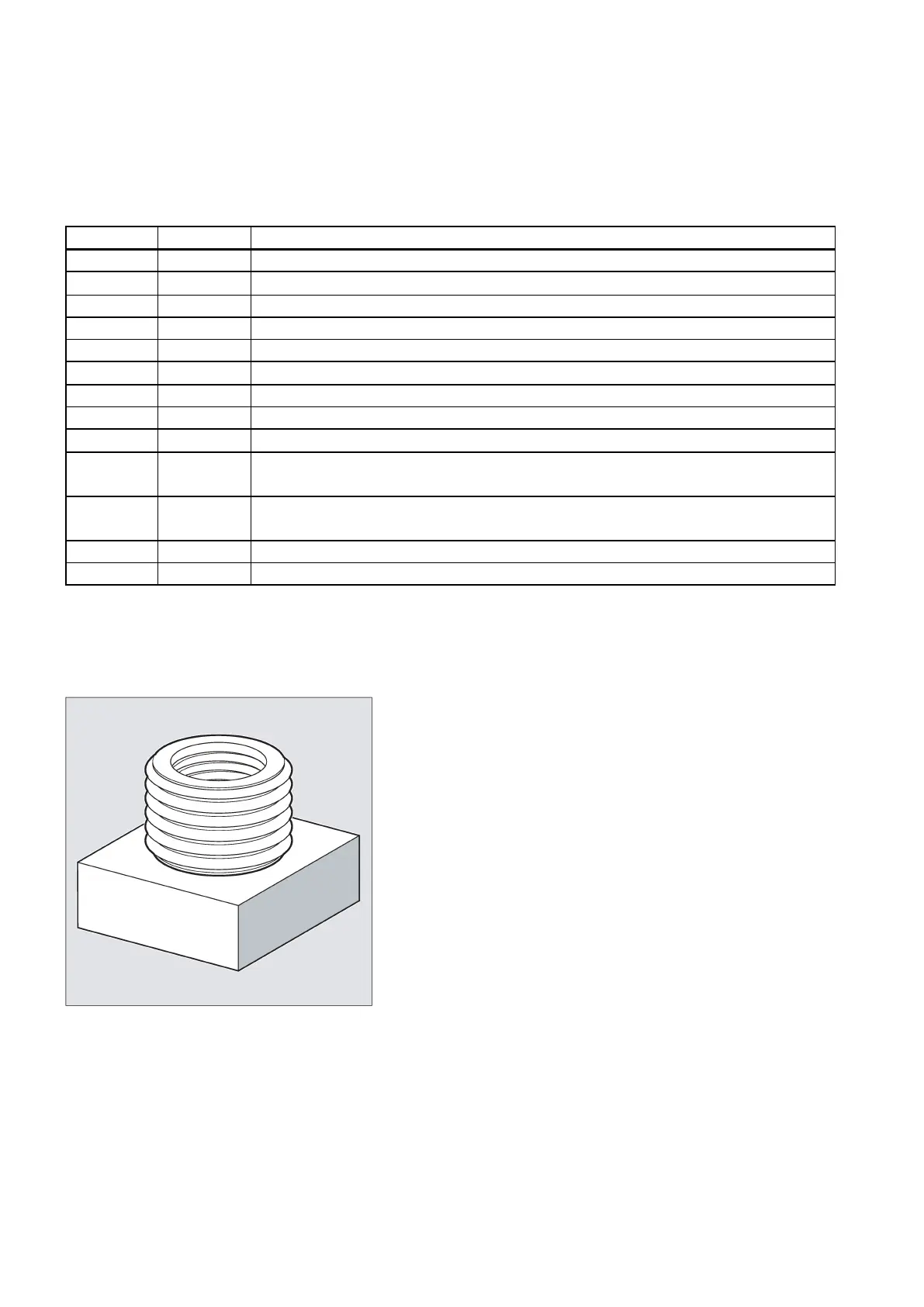

By using the cycle CYCLE90, you can produce internal or external threads. The path when milling threads is based on a

helix interpolation. All three geometry axes of the current plane, which you define before calling the cycle, are involved in this

motion.

Sequence for external thread

Position reached prior to cycle start:

The starting position is any position from which the starting position at the outside diameter of the thread at the height of the

retraction plane can be reached without collision.

Loading...

Loading...