4.7 SOS

Definition according to EN 61800-5-2:

"This SOS function is used for safe monitor‐

ing of the standstill position of a drive."

Example of how the function can be used

Example Possible solution

A protective door must only be opened if a motor is in

the safe standstill state.

● Select SOS

● A higher-level controller brakes the axis (e.g.

position-controlled) down to standstill within

the configured time between the selection of

SOS and when it becomes active.

● Standstill is then safely monitored via the

SOS function.

The protected machine areas can be entered without having to shut down the machine as long

as SOS is active.

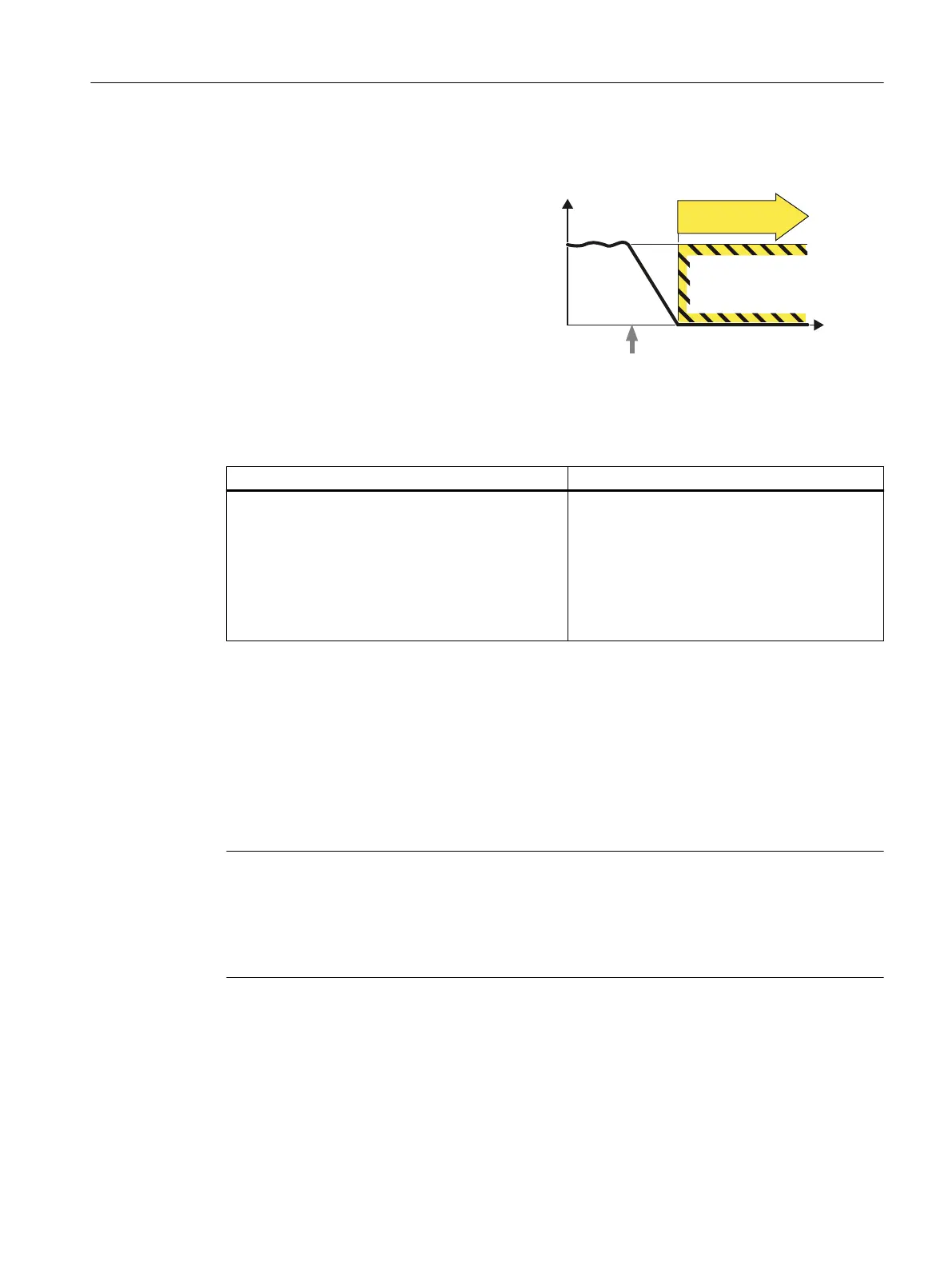

After SOS has been selected it becomes active after the parameterizable delay time has

expired. The drive must be braked to standstill within this delay time (e.g. by the controller).

Drive stopping is monitored using an SOS tolerance window. When this function is activated,

the current actual position is saved as a comparative position, until SOS is deselected again.

Any delay time is cleared after SOS is deselected and the drive can be immediately moved.

The drive is stopped with SS1 when the standstill tolerance window is violated.

Note

Contrary to SS1 and SS2, SOS does not automatically brake the drive

The control still enters the setpoint.

This means that in the user program of the control system, the system must respond to the

"SOS selected" bit so that the control system brings the drive to a standstill within the delay time.

Safety functions integrated in the drive

4.7 SOS

Safety Integrated (with SINAMICS S120)

Commissioning Manual, 02/2020, A5E46305916B AB 125

Loading...

Loading...